6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar represent a cornerstone in marine engineering, providing unmatched durability, machinability, and corrosion resistance. Particularly suited for harsh saltwater environments, 6061 is widely adopted for constructing structural components, frameworks, and specialized marine applications where both strength and resistance to corrosion from seawater are essential.

What is 6061 Marine Aluminum?

6061 alloy is a precipitation-hardened aluminum alloy primarily composed of magnesium and silicon. When specially tempered and processed using recognized marine industry standards, it becomes an ideal candidate for marine applications.

The 6061 marine aluminum rods and bars produced under stringent quality control conform to ASTM B221 (for extruded bars) and AMS-QQ-A-200 standards. These ensure high mechanical integrity, optimal tensile strength, and superior corrosion resistance, especially against seawater exposure.

Applications of 6061 Marine Aluminum Rod & Bar

- Shipbuilding: Structural frames, railing bars, and fittings

- Boat Masts and Superstructures: Lightweight yet strong frameworks

- Decking and Railings: Resistant to salt spray and constant marine weather

- Propeller Shafts and Marine Hardware: High fatigue resistance with reliable performance

- Drainage & Plumbing Components used on ships

- Marine Electrical Equipment Frames

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.40 - 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 - 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 - 1.2 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical & Physical Properties

| Property | Value (Typical) |

|---|---|

| Density | 2.70 g/cm³ |

| Yield Strength (T6 temper) | ≥ 240 MPa |

| Tensile Strength (T6 temper) | 275 - 310 MPa |

| Elongation (in 2 inches) | 8 - 12 % |

| Hardness (Brinell) | 95 HB |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | ~167 W/m*K |

Temper Designations and Processing

- O (Annealed): Soft and ductile for forming and welding purposes. Excellent machining but lower strength.

- T4 (Solution Heat Treated and Naturally Aged): Moderate strength with modest corrosion resistance for use where intricate machine parts are needed.

- T6 (Solution Heat Treated and Artificially Aged): The most common temper used in marine engineering, combining superior strength and corrosion resistance.

The temper significantly affects mechanical properties. For durable marine-grade products, the T6 temper is recommended for rods and bars to resist mechanical wear due to saltwater.

Resistance to Corrosion in Marine Environments

6061 marine aluminum rod & bar offers excellent corrosion resistance, thanks to a naturally forming oxide layer enhanced by alloying elements like chromium and magnesium. When compared to other 6xxx alloys, 6061 provides an optimized balance between strength and resistance to oxidization and seawater attacks, reducing the risk of pitting corrosion—a critical attribute in marine environments.

Surface treatments such as anodizing or powder coating can further improve longevity and protect the base material under constant exposure to UV rays, salt spray, and temperature fluctuations prevalent at sea.

Manufacturing Standards and Compliance

- ASTM B221: Defines the standard specification for aluminum and aluminum-alloy extruded bars, rods, wires, shapes, and tubes.

- AMS-QQ-A-200/8: Covers aerospace and marine DTD requirements for corrosion-resistant weldable aluminums.

- ISO 9001 Certification: Maintains fabrication and quality standards.

- ABS and DNV Certification: For marine-grade alloy certification compliance on vessels.

Advantages of Choosing 6061 Marine Aluminum Rod & Bar

- High strength-to-weight ratio supporting lightweight fabrication

- Superior resistance to corrosion from seawater, avoiding frequent maintenance

- Good galvanic corrosion resistance optimal when joining with other marine metals

- Excellent machinability allowing precision manufacturing of complex parts

- Versatile temper offers customization based on specific usage requirements

- Readily weldable enabling intricate constructions

Related Products

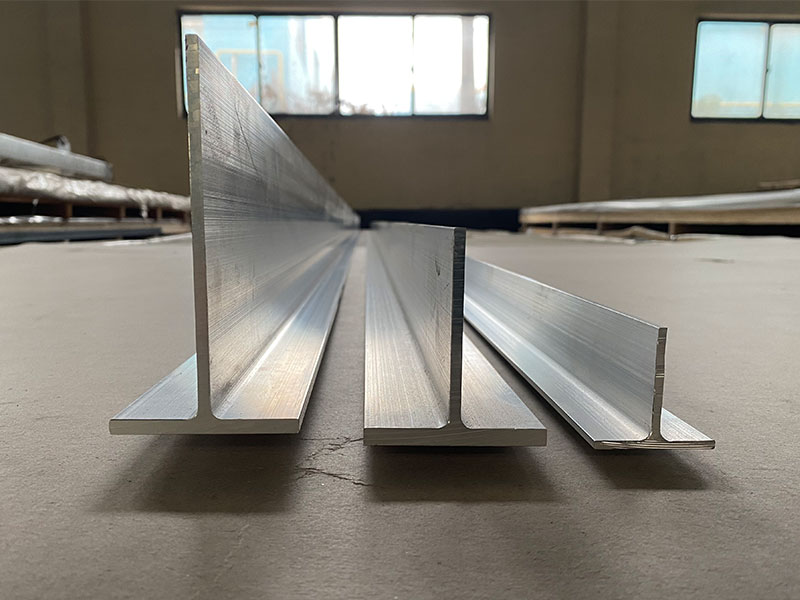

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details

Leave a Message