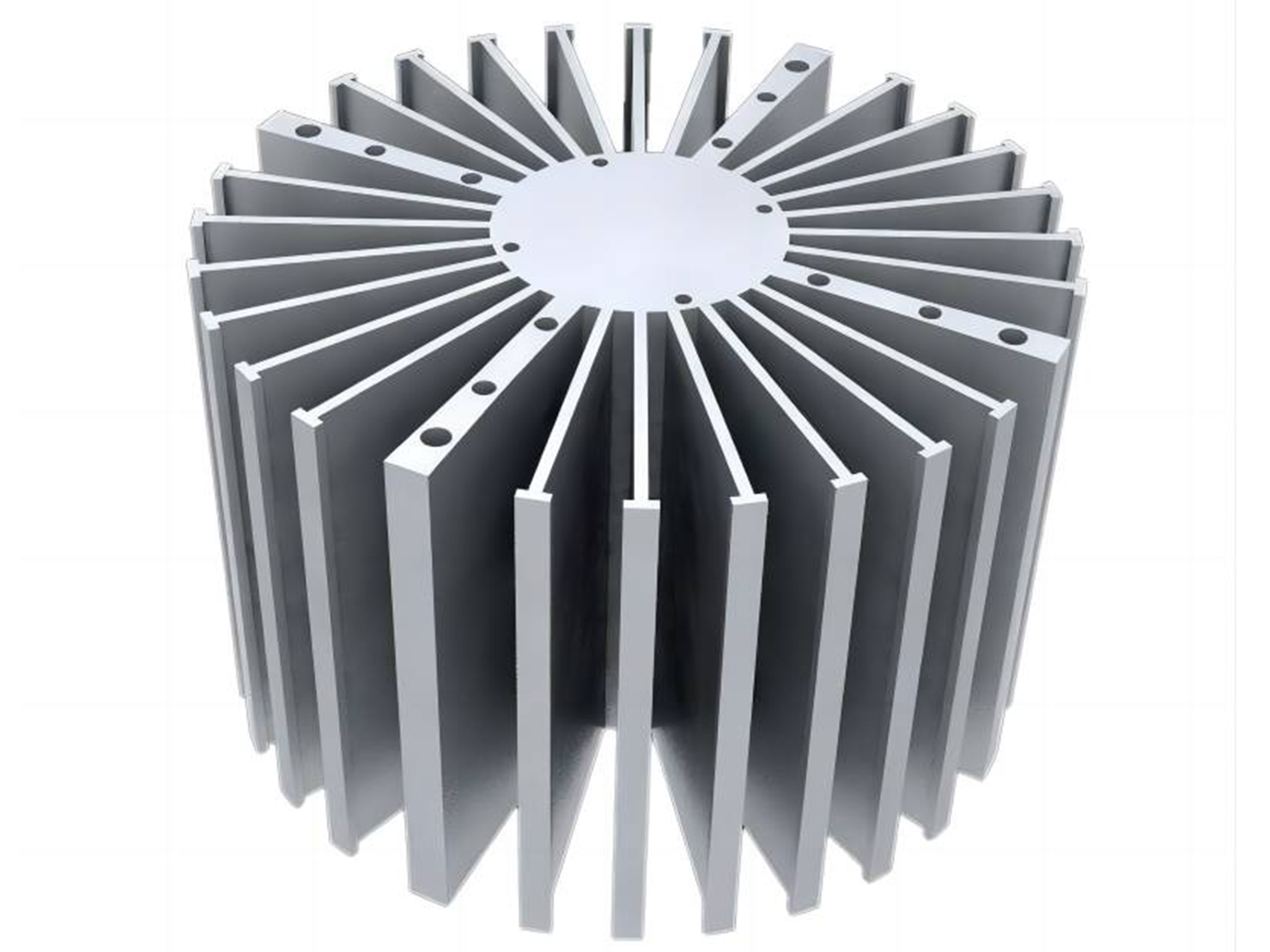

6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery. Among various materials used for heat sink fabrication, 6063 Marine Aluminum stands out due to its robust physical properties, excellent corrosion resistance, and versatile processing capabilities.

6063 Marine Aluminum Alloy

The 6063 aluminum alloy is an extrusion-grade material that belongs to the 6000-series aluminum-magnesium-silicon alloys, known for their strength, weldability, and corrosion resistance. It has become the industry standard for marine extrusions due to its balanced mechanical properties and excellent surface finish potential.

Chemical Composition of 6063 Alloy (% by weight):

| Element | Composition Range |

|---|---|

| Aluminum | Remainder |

| Silicon (Si) | 0.2 – 0.6 |

| Magnesium (Mg) | 0.45 – 0.9 |

| Iron (Fe) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.1 |

| Manganese (Mn) | ≤ 0.1 |

| Chromium (Cr) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.1 |

| Others | ≤ 0.05 (each), ≤ 0.15 total |

Notably, the low copper content enhances corrosion-resistance significantly, which is crucial for marine environments where saltwater corrosion is persistent and aggressive.

Alloy Tempering and Mechanical Properties

6063 alloy offers several temper designations based on its thermal and mechanical treatments:

- T5: Cooled from an elevated temperature shaping process and artificially aged

- T6: Solution heat-treated and artificially aged, providing the best strength

| Property | Metric Value | Unit |

|---|---|---|

| Ultimate Tensile Strength | 190 - 240 | MPa |

| Yield Strength | 125 - 145 | MPa |

| Elongation at Break | 8 - 12% | % |

| Density | ~2.7 | g/cm³ |

| Thermal Conductivity | Approx. 201 | W/m·K |

For heat sink applications, the T5 and T6 tempers are preferred due to the balance of strength and ductility allowing for complex extrusion profiles while maintaining durability.

6063 Aluminum Heat Sink Profile: Functionalities in Marine Applications

- High Thermal Conductivity for Efficient Cooling

Aluminum’s inherent thermal conductivity (approximately 201 W/m·K) ensures rapid dissipation of heat generated by offshore electronic controllers, LED lighting systems, and communication devices. The 6063 alloy used in heat sinks is shaped into precision extrusions with optimized fin geometries that maximize surface area exposure to seawater or ambient air for accelerated heat transfer.

- Superior Corrosion Resistance in Aggressive Marine Environments

The silicon-magnesium content coupled with low copper yields strong resistance to saltwater corrosion, protecting the heat sink’s structural integrity and thermal performance during long-term offshore exposure. Additional anodizing treatments further enhance corrosion resistance, texture hardness, and weather-resistant properties, extending long service life.

- Light Weight Yet High Strength

In offshore systems where weight reduction impacts installation and maintenance costs, 6063 aluminum balances mechanical strength (yield up to ~145 MPa in T6) and light weight (density ~2.7 g/cm³), outperforming heavier metals historically used for heat sinks.

- Customization Flexibility

6063’s excellent extrusion characteristics allow manufacturers to deliver sophisticated heat sink profiles engineered for specific platform constraints. Complex multi-fin and hollow sections for liquid-cooling channels can be realized with tight dimensional tolerances, fulfilling stringent offshore CAD design specifications.

Implementation Standards for Marine Aluminum Heat Sink Profiles

To meet quality and safety demands, the production of 6063 marine aluminum heat sink profiles adheres to:

- ASTM B221/B221M-20: Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes

- ISO 6361: Aluminum and aluminum alloys — Wrought products — Chemical composition and mechanical properties

- ABS/CCS/DNV-GL Marine Class Certifications: Specific certifications that ensure marine-grade material acceptance for offshore usage

Compliance ensures that extrusions maintain uniform chemical properties and mechanical performances suitable to operational marine environments including mechanical vibration, salt spray, and thermal shock conditions.

Typical Applications in Offshore Equipment

- Heat Sinks for Marine Electronics Control Units: Protect solid-state circuits onboard drilling rigs and floats

- Cooling Profiles for LED Marine Lighting: Maintain luminous efficiency by extracting heat

- Thermal Management in Power Conversion Cabinets: Keep inverters and rectifiers cool in electrical pods

- Structural Heat Transfer Components: Combined mounting and cooling elements for sensor arrays and marine radar

Related Products

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

Marine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View Details6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

Advantages of 6063 marine aluminum heat sink profiles, engineered to provide superior thermal management and corrosion resistance for coastal platform electronics. Ideal for harsh maritime environments.

View Details

Leave a Message