Marine Aluminum Customized Shapes for Custom Boat Frame Construction and Design

When it comes to constructing custom boats, marine aluminum rises to the occasion—offering versatility, rigidity, and corrosion resistance needed for aquatic environments.

The Surge in Demand for Custom Boat Frames

The maritime industry continues to evolve with bespoke designs taking precedence for recreational enthusiasts and commercial entities alike. Custom boat frames not only enhance aesthetic appeal but also amplify performance and durability—a trend where marine aluminum plays an essential role.

Why Artificially Create Boat Frames?

- Lightweight Design: Enabling greater speed with less energy expenditure.

- Corrosion Resistance: An essential property when faced with saltwater exposure.

- Workability: Ease of fabrication for unique shapes and attenuates weldability requirements.

Marine Aluminum Profiles: Custom Shapes Defined

Custom shapes of marine aluminum are derived from versatile alloys specifically tailored for maritime applications. Manufacturers excel by producing varied profiles—channels, angles, squares, and DTOs (double-tapered outriggers), all customized to individual specifications.

Parameters of Custom Shapes

- Thickness & Gauge: A customizable area can deal with different gauge thicknesses which are pivotal for structural integrity.

- Length/Width/Height: Specification hinges significantly on design needs. Custom dimensions accommodate modifications that adhere to engineering requirements.

- Bend Radius: Sharper bending leads improve design flexibility to angles cleaner and yield optimum stress distribution.

Standards and Implementation: What You Need to Know

To promote the buyer's confidence in their engineering approximations, custom marine aluminum should comply with standardized norms like the American Society for Testing and Materials (ASTM) and the American Welding Society (AWS). Shipbuilders usually refer to these standards in the specification documents when drafting immediate plans.

Differentiating Alloy Tempers

alloy temper structuring is equally when delving into its frame capabilities. Standard NM-grade industrial and marine grade 5000 series (such as the widely known 5083 and 5052) are distinct in their temper classifications varied from H, F, O, or T characteristics, marking their stiffness and elasticity conformation.

Chemical Properties & Alloy Table

Marine aluminum’s resistance properties often hinge on its chemical composition. Here’s a quick comparison of notable grades commonly used in the marine environment:

| Alloy Grade | Major Alloying Elements | Main Properties | Registered Temper | Diameter Limits (mm) |

|---|---|---|---|---|

| 5083 | 4.5% Mg, 0.5% Cr | Exceptional performance in severe conditions; Influences weldability; Ultimate strength. | H116 | |

| 5052 | 2.5% Mg | Better workability combined with corrosion resistance. Maintain weld endurance. | H32 |

The temper condition spotlight matters, as each structural manipulation defaults to certain uses—where the elimination or change in production processes resolves to properties aligning favorably for boating apps.

Spectacular Joinery Procedures

Custom boat frame creation leverages successful procedures combining marine aluminum’s customized geometry merging together plate or section specs efficiently, profitable behavior evident post-application stress. Approaches linked compose strong joints; often laser-cutting is determined for sharp yields—a refinement marrying freedom with craftsmanship.

Advantages of Customized Shapes for Boat Frames

Harnessing marine aluminum’s characteristics translates fluid dynamics and weight matching into artful progress:

- Enhanced fuel efficiency demands cohesion refinement through kinetics.

- Improved Responsive Frameworks assures adaptability for soft straits or tricky torrents.

- Potential reduction in non-calcified leaks by its lighter presence opposed to heavier compromises, deslopping operational surveys ahead.

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

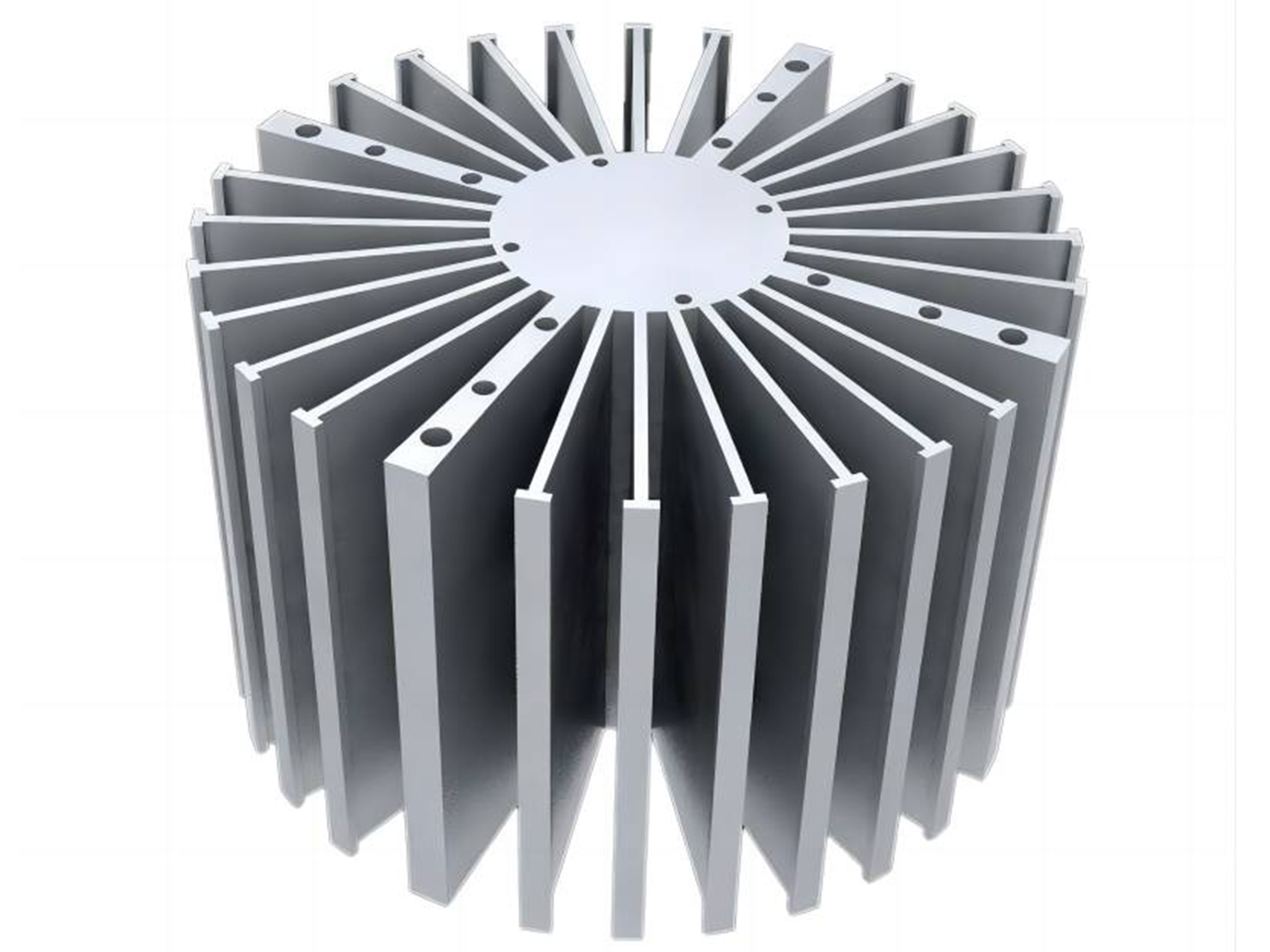

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

6061 Marine Aluminum Fencing and Railings for Lightweight Coastal Deck Railings

6061 marine aluminum is renowned for its excellent qualities, making it one of the top choices for lightweight coastal deck railings and fencing solutions. Designed specifically for marine environments, its exceptional resistance to corrosion.

View Details6061 Marine Aluminum Fencing and Railings for Custom Offshore Deck and Railings

6061 Marine Aluminum fencing and railings provide a lightweight, corrosion-resistant, high-strength solution for custom offshore decks and railings.

View Details6063 Marine Aluminum Heat Sink Profile for Coastal Platform Electronics

Advantages of 6063 marine aluminum heat sink profiles, engineered to provide superior thermal management and corrosion resistance for coastal platform electronics. Ideal for harsh maritime environments.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details6061 Marine Aluminum Customized Shapes for Lightweight Offshore Platform Design

Explore how 6061 marine aluminum customized shapes offer superior strength, corrosion resistance, and lightweight characteristics essential for innovative offshore platform design, enabling robust and efficient marine structures.

View Details6061 Marine Aluminum Customized Shapes for Saltwater Resistant Shipbuilding Frames

Marine aluminum alloys play a critical role in shipbuilding, exhibiting remarkable resistance to corrosion, high strength-to-weight ratios, and ease of fabrication.

View Details

Leave a Message