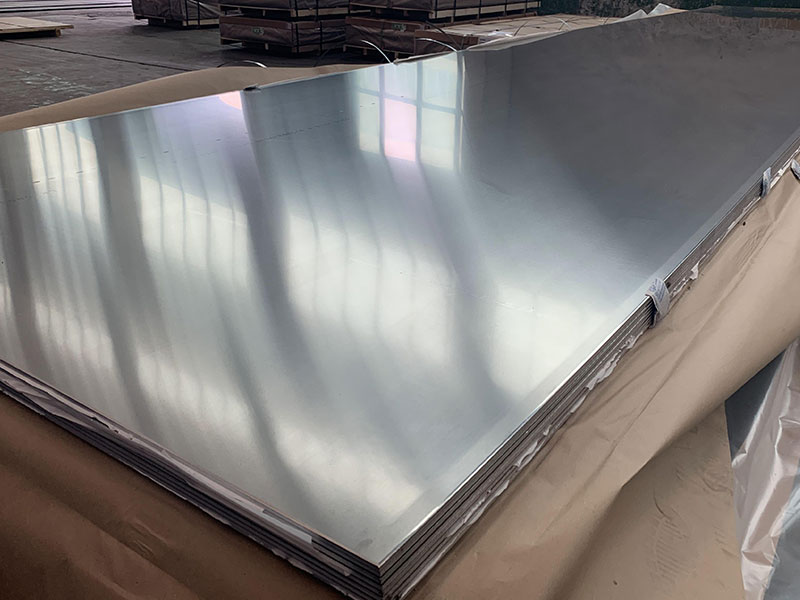

Aluminium plate marine grade

Marine environments are uniquely punishing: salt spray, humidity, temperature cycling, abrasion, and galvanic couples all work together to attack metal. Aluminium plate marine grade is engineered to thrive in these conditions by combining corrosion resistance, strength-to-weight efficiency, and dependable fabrication performance. For boatbuilders, shipyards, offshore contractors, and coastal infrastructure projects, marine-grade aluminium plate offers a practical path to long service life with reduced maintenance compared to many steels.

What "Marine Grade" Means

In aluminium plate, marine grade generally refers to alloys that have demonstrated strong resistance to seawater corrosion and retain good mechanical properties after welding. In practice, the most common marine-grade plate families are:

- 5xxx series (Al-Mg) such as 5083, 5086, 5454, 5754

- Selected 6xxx series (Al-Mg-Si) such as 6061, 6082 (often for extrusions and structural components; plate is also used)

For immersed or splash-zone service, 5xxx alloys dominate because of their excellent resistance to chloride-driven corrosion and strong weldability. For machined structural parts where higher yield strength and heat-treat capability are valuable, 6xxx alloys are often chosen-typically with added attention to corrosion design and isolation from dissimilar metals.

Features Customers Value

| Feature | What it means in service | Typical benefit |

|---|---|---|

| Seawater corrosion resistance | Strong resistance to pitting and general corrosion in chloride environments | Longer life, less coating dependency |

| High strength-to-weight | Good mechanical strength at low density | Faster vessels, higher payload, easier handling |

| Weldability | Stable properties and low defect sensitivity in welded structures | Efficient fabrication, reliable joints |

| Toughness at low temperature | Maintains toughness in cold marine climates | Safer structures in harsh regions |

| Formability | Good bending and forming for hull plating and superstructures | Cleaner fabrication, fewer seams |

| Recyclability | Aluminium is widely recycled with high retained value | Better lifecycle economics |

Common Marine-Grade Alloys and Tempers

Marine plate is usually supplied in tempers that balance strength, workability, and stress-corrosion performance.

| Alloy | Alloy family | Common tempers (plate) | Typical marine use |

|---|---|---|---|

| 5083 | Al-Mg-Mn | H116, H111, H321 | Hulls, decks, bulkheads, high-performance structures |

| 5086 | Al-Mg | H116, H111 | Hull plating, tanks, welded assemblies |

| 5454 | Al-Mg | H32 | Pressure vessels, fuel/chemical tanks, heat-affected zones with good stability |

| 5754 | Al-Mg | H111, H22/H24 | Superstructures, interior panels, general marine fabrication |

| 6061 | Al-Mg-Si | T6, T651 | Machined parts, frames, fittings, structural members |

| 6082 | Al-Mg-Si | T6, T651 | European structural plate applications, machined components |

Temper notes (quick guide)

- H116 / H321 are widely used for marine 5xxx plate because they are designed to improve corrosion performance in seawater service while maintaining strength.

- T6 / T651 indicate solution heat-treated and artificially aged (with T651 stress-relieved by stretching), often preferred for dimensional stability in machining.

Chemical Composition (Typical Ranges)

Actual limits vary by standard and product form. Confirm exact chemistry to the governing specification for your project.

5083 (Marine Plate Standard Workhorse)

| Element | Typical range (wt%) |

|---|---|

| Mg | 4.0–4.9 |

| Mn | 0.4–1.0 |

| Cr | 0.05–0.25 |

| Si | ≤0.40 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Al | Balance |

5086 (Excellent Welded Hull Plate)

| Element | Typical range (wt%) |

|---|---|

| Mg | 3.5–4.5 |

| Mn | 0.2–0.7 |

| Cr | 0.05–0.25 |

| Si | ≤0.40 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Al | Balance |

6061 (Structural, Machinable Marine Component Plate)

| Element | Typical range (wt%) |

|---|---|

| Mg | 0.8–1.2 |

| Si | 0.4–0.8 |

| Cu | 0.15–0.40 |

| Cr | 0.04–0.35 |

| Fe | ≤0.70 |

| Mn | ≤0.15 |

| Zn | ≤0.25 |

| Ti | ≤0.15 |

| Al | Balance |

Mechanical Properties (Typical Values)

Properties depend on thickness, orientation, and standard. The values below are representative for common supply conditions.

| Alloy / Temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Notes |

|---|---|---|---|---|

| 5083-H116 | 305–350 | 215–250 | 10–16 | Excellent hull plate choice |

| 5083-H321 | 305–350 | 215–250 | 10–16 | Stable for welded structures |

| 5086-H116 | 275–340 | 200–240 | 10–16 | Very good welded performance |

| 5754-H111 | 190–240 | 80–130 | 12–22 | Great formability, moderate strength |

| 6061-T6 / T651 | 290–320 | 240–280 | 8–12 | Strong, machinable; corrosion design matters |

Technical Specifications Customers Commonly Request

Dimensional Supply (Typical Capabilities)

Availability varies by mill and region; these ranges reflect common stocking and production practice.

| Parameter | Typical range |

|---|---|

| Thickness | 3–150 mm (stock); thicker plate may be available by inquiry |

| Width | 1000–2500 mm |

| Length | 2000–12000 mm |

| Flatness | Controlled by plate class; tighter tolerances available |

| Surface finish | Mill finish; optional brushed or patterned finishes |

| Protection | PVC film, paper interleaving, export seaworthy packing |

Physical Properties (Useful for Design)

| Property | Typical value (5xxx marine plate) | Typical value (6061) |

|---|---|---|

| Density | ~2.66–2.68 g/cm³ | ~2.70 g/cm³ |

| Thermal conductivity | ~110–140 W/m·K | ~167 W/m·K |

| Electrical conductivity | Moderate | Moderate |

| Melting range | ~570–640 °C | ~582–652 °C |

Performance in Marine Corrosion Conditions

Marine-grade aluminium plate resists corrosion primarily through a stable oxide film and the alloy's chemistry. In real-world marine service, performance is strongly influenced by design and fabrication practices.

| Marine exposure zone | Typical risk | Recommended alloy family |

|---|---|---|

| Immersed seawater | Pitting, crevice corrosion | 5xxx (5083/5086/5454) |

| Splash / tidal zone | Wet-dry cycling, chloride concentration | 5xxx preferred; good detailing and drainage essential |

| Atmospheric coastal | Salt spray, staining | 5xxx or 6xxx with good coating/anodizing practice |

| Dissimilar metal contact | Galvanic corrosion | Any alloy needs isolation strategy |

Fabrication, Welding, and Finishing Notes

| Topic | Practical guidance for customers |

|---|---|

| Welding | 5xxx plate welds efficiently with common marine filler choices; control heat input and cleanliness for best results |

| Heat treatment | 5xxx is non-heat-treatable; strength is from work hardening. 6xxx is heat-treatable and often supplied in T6/T651 |

| Forming | 5754 and 5086 are very friendly for bending; 5083 offers strong performance with slightly higher forming loads |

| Machining | 6061-T651 is often preferred for tight tolerances and stable machining |

| Surface protection | Marine coatings and anodizing improve durability; even "marine grade" benefits from good coating design |

| Galvanic isolation | Use insulating gaskets, sleeves, coatings, and proper fastener selection when joining to steel, copper alloys, or carbon composites |

Typical Applications

| Application | Why marine aluminium plate fits |

|---|---|

| Boat and ship hulls | High strength-to-weight, corrosion resistance, weldable large plates |

| Decks and superstructures | Reduced top weight improves stability and fuel efficiency |

| Offshore walkways, platforms | Durable in salt-laden air, easy modular fabrication |

| Fuel, water, and process tanks | Selected 5xxx alloys offer reliable corrosion performance and weld integrity |

| Gangways, ramps, pontoons | Lightweight handling, strong in service, good repairability |

| Coastal infrastructure | Ladders, covers, housings, and panels with long service life |

How to Specify the Right Plate Quickly

| What to decide | Practical recommendation |

|---|---|

| Primary environment | Immersed/splash zone favors 5083/5086; structural machined parts often favor 6061 |

| Welded or machined? | Heavy welding: 5xxx. Tight machining and fixtures: 6061-T651 |

| Target thickness and flatness | Confirm plate class, tolerances, and stress-relief needs |

| Certification needs | Request mill test certificate, traceability, and standard compliance for marine projects |

| Corrosion design | Plan drainage, avoid crevices, isolate dissimilar metals, and consider coatings |

Aluminium plate marine grade-commonly 5083-H116/H321 and 5086-H116-is designed for seawater durability, excellent weldability, and high strength-to-weight performance. It is widely used in boat hulls, decks, offshore structures, tanks, and coastal equipment, offering reliable corrosion resistance in immersed and splash-zone environments. With clear alloy selection, proper fabrication, and galvanic isolation, marine-grade aluminium plate delivers lightweight construction, long service life, and lower maintenance in demanding marine conditions.

Related Products

Marine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsRelated Blog

Marine aluminium plate 5059

Marine Aluminium Plate 5059 is a high-strength alloy specifically designed for maritime applications. The versatile and durable properties of 5059 aluminum make it well-suited for a variety of marine structures.

View DetailsAluminium plate boat fishing boat alloy 5083

Aluminium alloy 5083 is a high-strength, corrosion-resistant marine aluminium widely used for fishing boats, workboats, ferries, and other offshore structures. Its combination of mechanical performance, weldability.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View Details1.5mm Aluminum Plate for The Marine

The 1.5mm Aluminum Plate is a crucial material employed in marine applications due to its exceptional resistance to corrosion, lightweight nature, and high strength-to-weight ratio.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View Details6061 T6 T651 Marine Grade Aluminum Plate Sheet

When it comes to selecting the ideal material for marine applications, nothing quite matches the balanced strength, corrosion resistance, and versatility of the 6061 T6 T651 marine grade aluminum plate sheet.

View Details

Leave a Message