5083 Marine Grade Aluminum Plate for Shipbuilding

When people picture shipbuilding, they tend to imagine big welds, thick steel, and dramatic launches. Yet some of the most important decisions are almost invisible: alloy choice, temper condition, plate flatness, and how a material behaves after kilometers of welding. From that quieter, more practical angle, 5083 marine grade aluminum plate earns its reputation not because it is trendy, but because it is predictable-especially where seawater, cyclic loads, and fabrication reality meet.

5083 is widely specified for ship hull plating, decks, bulkheads, superstructures, ramps, and high-strength marine components because it offers an unusually balanced combination of corrosion resistance in seawater, high as-welded strength, and excellent toughness at low temperatures. In the language of the yard, it is the alloy that "keeps its manners" after welding and service exposure.

Why 5083 Is a True Marine Grade Aluminum Plate (Not Just "Corrosion-Resistant")

Many aluminum alloys resist corrosion in air. Marine service is different: chlorides, crevice conditions, wet-dry cycles, and dissimilar-metal contact create a harsher, more complex environment. The signature of 5083 is its high magnesium content. Magnesium strengthens aluminum through solid-solution strengthening, and in the right temper it produces high mechanical performance without needing heat treatment. This matters in shipbuilding because hull plates are cut, formed, and welded extensively; heat-treatable alloys can lose properties or become difficult to manage around welds.

From a shipbuilder's viewpoint, the real selling point is not only "good corrosion resistance," but confidence in the heat-affected zone. 5083 maintains solid performance in welded structures and is known for good resistance to seawater corrosion and strong structural behavior in the H116/H321 conditions commonly specified for hull applications.

5083 Alloy Tempering Conditions: Reading the Plate Like a Builder

Shipbuilders do not buy an alloy; they buy an alloy plus a temper that defines stability, strength, and resistance to marine-specific degradation.

Common tempers for 5083 marine aluminum plate include:

H116

Used heavily for marine plate. It is strain-hardened and processed to provide improved resistance to exfoliation corrosion. This is a classic choice for hull plating and structural members exposed to seawater.

H321

Also widely used in marine structures. It is strain-hardened and stabilized to reduce susceptibility to certain forms of corrosion while maintaining strong mechanical properties.

O (Annealed)

Chosen when maximum formability is required. It is easier to shape but has much lower strength, so it is typically reserved for parts where forming dominates and loads are modest.

A practical distinction many procurement teams overlook is that temper is not just strength; it is also a statement about how the plate behaves after fabrication and exposure, including corrosion behavior in marine atmospheres.

Technical Parameters That Matter in Shipbuilding (Beyond "Thickness and Size")

In shipbuilding, a plate is not judged only by its mill test certificate; it is judged by how it behaves on the shop floor.

parameters typically controlled or specified include:

Thickness range and dimensional availability

5083 plate is available across a wide thickness band for ship structures, from lighter deck and superstructure plate to heavier hull and ramp sections. Wider and longer plates reduce weld length, which reduces distortion and labor.

Flatness and residual stress

Marine fabrication is distortion-sensitive. Better flatness and lower residual stress improve fit-up, reduce rework, and help maintain hull fairness.

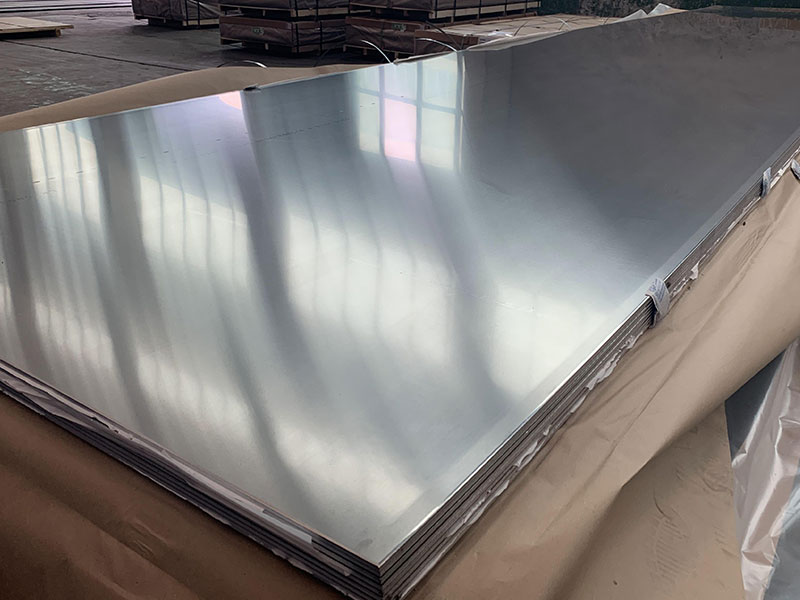

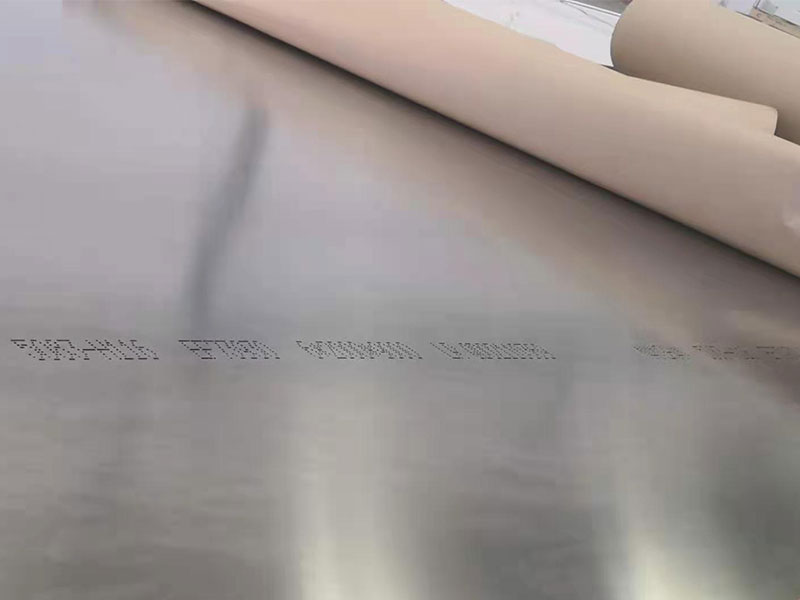

Surface quality and edge condition

Consistent surface and clean edges support stable welding, reduce porosity risk, and improve coating performance where coatings are used.

Weldability and as-welded performance

5083 is known for good weldability using common marine aluminum filler alloys. The design reality is that the as-welded joint and heat-affected zone performance often governs, not the base metal ultimate strength in the certificate.

Implementation Standards and Common Shipbuilding Specifications

5083 marine grade aluminum plate is commonly supplied and verified under widely recognized standards and classification expectations. Actual project requirements vary by yard, flag state, and class, but typical frameworks include:

ASTM standards

ASTM B928 is frequently used for marine-grade plate (including 5083) because it focuses on corrosion performance expectations relevant to seawater exposure. ASTM B209 is also used for general aluminum plate requirements.

EN standards

EN 485 and EN 573 are commonly referenced in markets using European norms, covering mechanical properties and chemical composition.

Classification society requirements

Marine projects often involve third-party inspection and certification. DNV, ABS, Lloyd's Register, and similar organizations may impose additional requirements for traceability, testing frequency, and documentation, particularly for hull structures.

In practical procurement, the most important point is alignment: selecting the standard that matches the service environment and the temper intended for hull exposure, then ensuring the MTC and inspection plan reflect that.

Chemical Composition of 5083 Marine Grade Aluminum (Typical Limits)

5083's performance is engineered into its chemistry. Magnesium is the headline, but small additions and limits on impurities protect corrosion behavior and consistency.

Below is a commonly referenced chemical composition range for AA 5083 (values in weight %). Exact limits can vary slightly by standard; always confirm against the governing specification for your project.

| Element | Typical Specification Range (wt. %) |

|---|---|

| Magnesium (Mg) | 4.0–4.9 |

| Manganese (Mn) | 0.4–1.0 |

| Chromium (Cr) | 0.05–0.25 |

| Silicon (Si) | ≤ 0.40 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

A distinctive way to interpret this table is to see it as a "corrosion and weldability contract." Tight limits on copper and controlled minor elements help keep the alloy stable in seawater and predictable during welding.

Typical Mechanical Property Expectations (Temper-Dependent)

Mechanical properties depend on thickness, processing route, and temper. For shipbuilding, 5083-H116 and 5083-H321 are commonly selected because they deliver a strong combination of strength and ductility while supporting marine corrosion performance.

Commonly cited ranges seen in industry for plate (temper- and thickness-dependent) include:

- Tensile strength often in the neighborhood of the low-to-mid 300 MPa range

- Yield strength often in the neighborhood of the 200+ MPa range

- Elongation that remains workable for forming and fabrication

For design, always use the values required by your governing standard and class approval, since minimums can change with thickness bands and testing direction.

Corrosion Behavior: The Marine Reality, Not the Brochure Version

In seawater service, the most expensive corrosion failures are not always uniform thinning; they are localized problems born from geometry and assembly.

5083 marine grade aluminum plate performs strongly when shipbuilding fundamentals are respected:

- Avoiding crevices and water traps that create persistent chloride concentration

- Controlling dissimilar-metal contact and using isolation strategies where needed

- Applying correct surface prep and coating systems when specified

- Selecting marine-appropriate tempers such as H116/H321 for exposed structures

A subtle but important procurement insight is that "marine grade" is not a single checkbox; it is the combination of alloy, temper, standard, and fabrication discipline.

Fabrication Notes That Shipyards Appreciate

5083 is popular partly because it fits shipyard rhythm.

Cutting and forming

It machines and cuts cleanly with appropriate parameters, and it can be formed effectively, especially in thinner gauges or softer tempers. For tighter radii, discuss forming requirements early so plate temper and process choices support the shape.

Welding

5083 welds well using established procedures. As with all aluminum welding, controlling cleanliness, heat input, and shielding practice makes the difference between "acceptable" and "production-grade repeatability."

Distortion control

Aluminum's thermal conductivity and expansion mean distortion management is part of the craft. Plate quality, fit-up, tack strategy, and sequence planning all matter.

The most valuable feature of 5083 marine aluminum plate for shipbuilding is not a single property like tensile strength. It is how the alloy reduces project risk across many small decisions:

- It reduces uncertainty in welded structural performance

- It supports long-term seawater exposure with proven marine tempers

- It helps yards maintain schedule by being cooperative in fabrication

- It aligns with common marine standards and class expectations

In other words, 5083 behaves like a "systems material." It does not just meet a specification; it helps the entire build-from cutting table to sea trials-stay predictable.

Choosing 5083 Marine Grade Aluminum Plate for Your Next Vessel

If your vessel design values durability in seawater, high strength-to-weight, and welded structure reliability, 5083 in H116 or H321 is often the most straightforward solution. The best procurement outcomes come from specifying the complete package: alloy + temper + implementation standard + inspection documentation, with plate quality metrics that match your yard's fabrication methods.

Related Products

Marine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsRelated Blog

AA 5083 505 5754 aluminum sheet plate for ship building

Marine aluminum alloys such as AA 5083, 5052, and 5754 have become the backbone of modern shipbuilding due to their exceptional strength, corrosion resistance, and lightweight nature.

View Details11 mm thick marine aluminium plate 5083

Marine industries demand materials that offer exceptional strength, corrosion resistance, and durability under harsh environmental conditions. The 11 mm thick marine aluminium plate 5083 is specifically designed to meet these rigorous standards.

View Details5083 marine grade aluminium plate

When it comes to marine construction and applications necessitating optimal performance in corrosive saltwater environments, 5083 marine grade aluminium plate stands out as one of the most reliable and versatile materials.

View DetailsMarine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View DetailsMill Finish Plate Aluminum Sheet 5083 H116 For Boat

Mill Finish Plate Aluminum Sheet 5083 H116 For Boat: A Deep-Dive From The Hull’s Point Of View When naval architects choose materials, they are not merely reading charts; they are imagining how a plate of metal will live its entire life in salt water.

View Details5083 hot rolled aluminium sheet plate for shipbuilding

5083 hot rolled aluminium sheet plate is a premium-grade aluminum product tailored specifically for shipbuilding applications. Renowned for its exceptional resistance to seawater corrosion, high strength, and easily weldable nature.

View Details

Leave a Message