Marine Aluminum Fencing and Railings for Durable Coastal Deck Protection

Coastal environments present unique challenges for construction materials, with high exposure to saltwater, humidity, and fluctuating temperatures. Marine aluminum fencing and railings have become the preferred choice for durable coastal deck protection, thanks to their outstanding corrosion resistance, strength, and aesthetic appeal.

Why Choose Marine Aluminum for Coastal Deck Protection?

Marine aluminum alloys are specifically engineered to withstand harsh maritime conditions without compromising structural integrity or appearance. Their attributes addressing coastal challenges include:

- Superior Corrosion Resistance: Aluminum naturally forms a protective oxide layer that guards against rust and oxidation, especially crucial in salty environments.

- Lightweight but Strong: Easier to handle and install compared to alternative metals, marine aluminum still offers robust support for safety railings and fences.

- Low Maintenance: Unlike steel, it does not require frequent painting or treatments, lowering long-term upkeep costs.

- Aesthetic Flexibility: Marine aluminum fences and railings can be styled to meet modern or traditional designs, including powder-coated finishes for color durability.

- Sustainability: Aluminum is 100% recyclable, aligning with eco-friendly building practices.

Applications of Marine aluminum fencing and railings

Marine-grade aluminum products are vital for various coastal deck installations where safety, longevity, and appearance are critical:

- Residential and commercial coastal balconies where constant exposure to marine elements occurs.

- Dock railings that demand resistance against salt spray and tidal actions.

- Harbor and marina environments requiring security fences coupled with corrosion-resistant properties.

- Coastal boardwalk railings subject to frequent lifting weather from ocean breezes.

- Specialty outdoor decks on cruise terminals or beach resorts aiming to fuse durability with design flair.

Technical Specifications and Properties

Alloy Selection & Temper Designation

Marine aluminum fencing and railing materials often use alloys from the 5xxx series, especially 5083 and 5086, known for corrosion resistance and marine suitability.

| Alloy | Temper | Description | Typical Applications |

|---|---|---|---|

| 5083 | H111 | As-rolled, non-heat-treatable | Marine structures, hull plates |

| 5086 | H32 | Strain hardened and partially annealed | Corrosion-resistant fencing and railings |

Typical Mechanical Properties

| Parameter | 5083-H111 | 5086-H32 |

|---|---|---|

| Tensile Strength (MPa) | 275 - 310 | 290 - 350 |

| Yield Strength (MPa) | 145 - 190 | 240 - 270 |

| Elongation (%) | 12 - 18 | 10 - 16 |

| Density (g/cm³) | 2.66 | 2.66 |

Chemical Composition (% by Weight)

| Element | 5083 Alloy | 5086 Alloy | Notes |

|---|---|---|---|

| Aluminum (Al) | Balance | Balance | Major element |

| Magnesium (Mg) | 4.0 - 4.9 | 4.0 - 5.0 | Enhances strength and corrosion resistance |

| Manganese (Mn) | 0.4 - 1.0 | 0.2 - 0.5 | Improved hardness |

| Iron (Fe) | ≤ 0.4 | ≤ 0.5 | Impurity limit |

| Silicon (Si) | ≤ 0.4 | ≤ 0.4 | Impurity limit |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | Low levels to reduce susceptibility to corrosion |

Industry Implementation and Recognized Standards

Using marine aluminum materials compliant with internationally accepted norms ensures product performance and safety:

| Standard | Scope | Remarks |

|---|---|---|

| ASTM B928 | Specification for Aluminum-Alloy Rolled Plates | Grades 5083, 5086 included |

| ASTM B209 | Aluminum Sheet and Plate Specification | Adopts temper designations like H111, H32 |

| ISO 10088 | Corrosion protection of aluminum and alloys | Design guidelines for marine corrosion resistance |

| 1144 Maritime Safety Code | Pin fold testing, structural design for marine assembling railing |

Installing Marine Aluminum Fences and Railings

Successful implementation of aluminum coastal fences and railings requires attentive consideration of material compatibility, anchoring methods, and finishing treatments. Implementers often choose powder coatings or anodizing for enhanced protection against ultraviolet rays and further corrosion resistance.

Mounting attachments manufactured with stainless steel fasteners avoid galvanic corrosion. Proper surface preparations such as cleaning and priming before installation ensure surface adhesion and durability.

Regular inspection is advisable to maintain connection tightness and structural stability, especially after storms when mechanical stress may challenge hardware supports.

Related Products

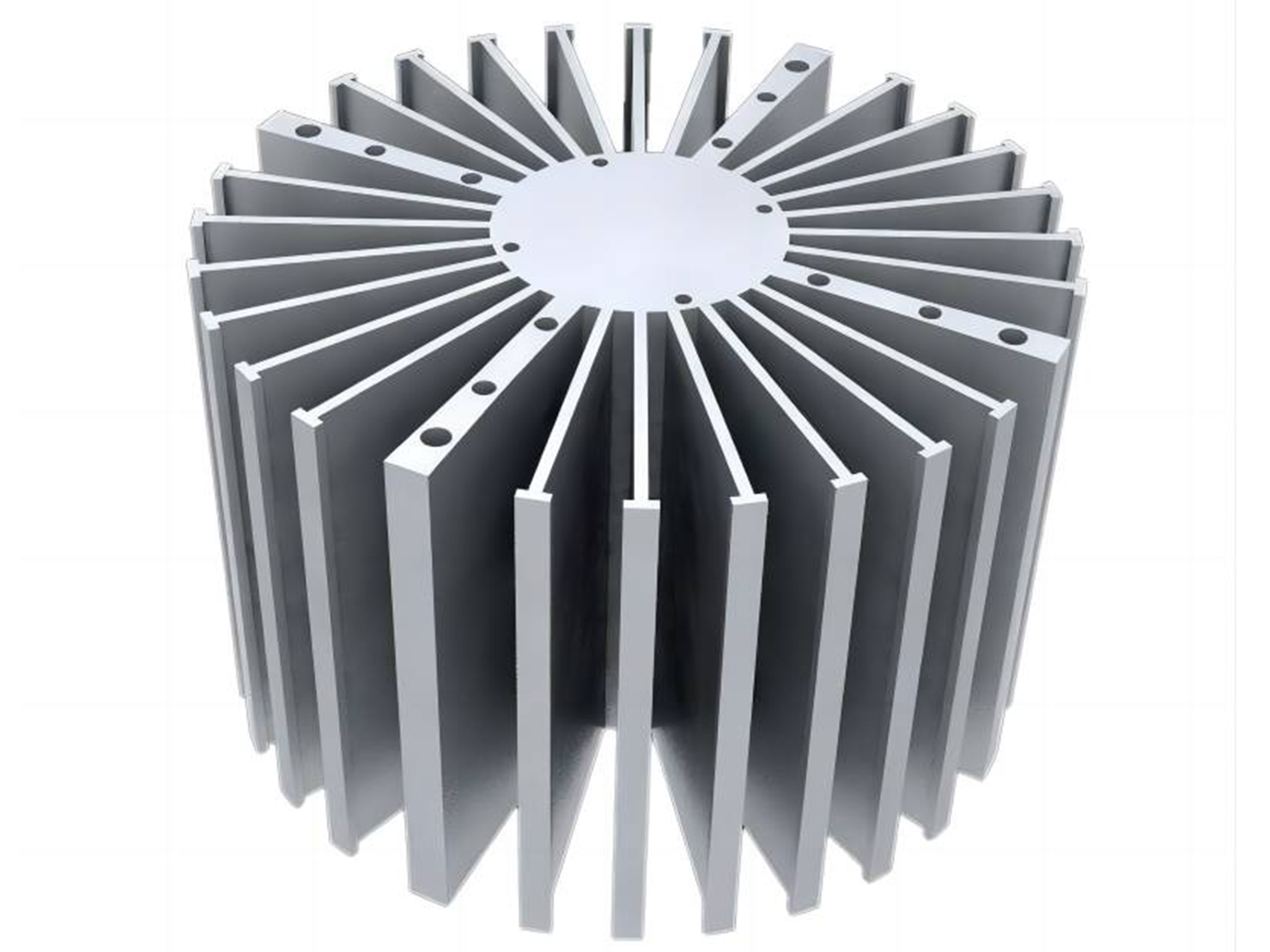

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

Marine Aluminum Customized Shapes for Custom Ship Deck and Railing Systems

In the ever-evolving maritime industry, safety, durability, and performance take precedence. Marine aluminum, recognized for its lightweight yet robust characteristics.

View Details5083 Marine Aluminum Fencing and Railings for Lightweight Offshore Guardrail Systems

When it comes to offshore guardrail systems, ensuring safety, durability, and corrosion resistance are paramount. 5083 Marine Aluminum has emerged as an excellent material choice for fencing and railings in marine environments.

View DetailsMarine Aluminum Customized Shapes for Custom Offshore Vessel Structural Parts

Manufacturing custom offshore vessel structural parts demands materials that combine exceptional strength, corrosion resistance, and ease of fabrication under challenging marine environments.

View Details6061 Marine Aluminum Fencing and Railings for Lightweight Coastal Deck Railings

6061 marine aluminum is renowned for its excellent qualities, making it one of the top choices for lightweight coastal deck railings and fencing solutions. Designed specifically for marine environments, its exceptional resistance to corrosion.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5052 Marine Aluminum Customized Shapes for High Strength Offshore Platforms

Superior qualities of 5052 Marine Aluminum, a high-strength material ideal for customized shapes used in offshore platforms. Learn about its key features, applications, and technical specifications.

View Details

Leave a Message