Marine Aluminum Profiles

Marine aluminum profiles are a cornerstone of modern marine design and construction. Their unique chemical properties and tempering standards make them not only lightweight but also incredibly robust for a variety of marine applications.

Importance of Marine Aluminum in Modern Shipping

Aluminum alloy provides an evolutionary leap in marine construction. As compared to steel, aluminum's lower density translates to significantly reduced weight without sacrificing strength, enhancing both speed and fuel efficiency in vessels. The strategic use of alloys, especially series 5000 and 6000, allows for enhanced corrosion resistance, an essential factor when exposed to saltwater exposure.

Properties and Features of Marine Aluminum Profiles

Resistance to Corrosion: Aluminum's inherent properties enable it to form a protective oxide layer, making marine aluminum profiles an ideal choice for shipbuilding and marine applications.

Mechanical Strength: Through tempering and alloying, aluminum offers increased mechanical strength, allowing for non-welded frame constructions that maintain structural integrity over time.

Lightweight: Reducing overall vessel weight not only speeds up transport but also increases overall efficiency leading to significant cost savings over time.

Thermal Conductivity: Marine aluminum profiles display excellent thermal conductivity, which is beneficial for heat dissipation in engine rooms and peak heat areas.

Alloy Tempering and Standards

The versatility of marine aluminum stems from a variety of tempering techniques that define its usability in different environments. Here’s a brief on some specific temper standards worth noting for marine applications:

- F Temper: As fabricated condition. Low strength with good formability.

- H Temper: Strain-hardened condition which offers increased ultimate tensile strength for most coast guard and specific industry inspections.

- T Temper: Heat-treated to bring higher durability characteristics to the material.

Implementation Standards for Marine Aluminum

Marine aluminum profiles must comply with strict performance and durability standards. The relevant standards include:

- ABYC (American Boat and Yachting Council) Compliance: This encompasses standard structural naval ratings and specifications for extrusions.

- DNV GL Certification (Det Norske Veritas - Germanischer Lloyd): A classification society which focus on the volume standards and endurance against harsh weather patterns.

Chemical Properties of Marine Aluminum

Like most materials, marine aluminum can be broken down by its distinctive weight percentages of elemental components. Below is a systematic overview:

| Element | Weight % Requirement |

|---|---|

| Magnesium (Mg) | 2.0 - 5.0 |

| Manganese (Mn) | 0.2 - 1.2 |

| Silicon (Si) | ≤ 0.6 |

| Copper (Cu) | ≤ 0.1 |

| Iron (Fe) | ≤ 0.7 |

| Zinc (Zn) | ≤ 0.25 |

| Other/Remaining | Balance |

Related Products

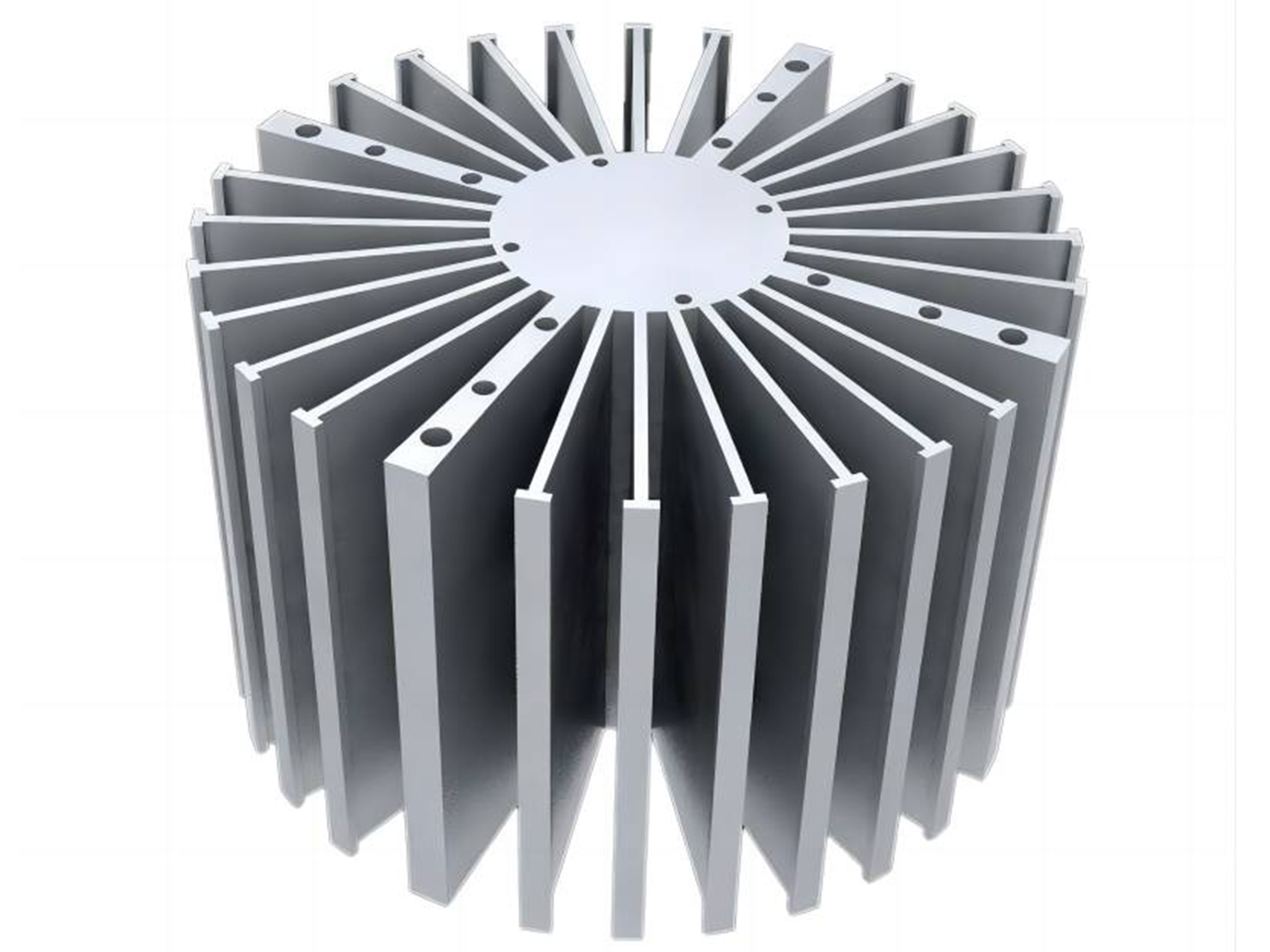

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

Marine Aluminum Fencing and Railings for High Strength Boat Deck Safety Barriers

When it comes to ensuring safety on boat decks, the choice of fencing and railing materials plays a critical role. Marine aluminum fencing and railings have emerged as the premier solution for high strength, corrosion-resistant.

View DetailsMarine Aluminum Heat Sink Profile for High Performance Heat Transfer in Coastal Equipment

High-performance Marine Aluminum Heat Sink Profile specially engineered for coastal equipment, offering superior corrosion resistance, thermal conductivity, and durability to ensure optimal heat transfer even in harsh marine environments.

View Details6061 Marine Aluminum Fencing and Railings for Lightweight Coastal Deck Railings

6061 marine aluminum is renowned for its excellent qualities, making it one of the top choices for lightweight coastal deck railings and fencing solutions. Designed specifically for marine environments, its exceptional resistance to corrosion.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View Details5052 Marine Aluminum Fencing and Railings for Saltwater Proof Marine Railing Systems

When it comes to marine applications, durability, corrosion resistance, and strength are non-negotiable. One material that stands out as a superior choice for fencing and railing systems on ships, docks, and coastal structures is 5052 Marine Aluminum.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View Details

Leave a Message