6082 Marine Aluminum Tubes for Superyacht Construction

6082 Marine Aluminum Tubes for Superyacht Construction

A Technical Deep Dive from a Designer’s Perspective

In modern superyacht construction, 6082 marine aluminum tubes occupy a quiet but critical role. They are rarely the visual focus of a yacht brochure, yet they shape how the vessel performs, how it feels under load, and how long it will last in aggressive marine environments.

Instead of treating 6082 tubes as just another stock item, it helps to view them like a structural “toolkit” for naval architects and marine engineers: a way to balance strength, weight, corrosion resistance, and fabrication flexibility in a single alloy system.

Below is a concise, application-driven look at 6082 marine aluminum tubes, tailored to superyacht needs.

Why 6082 Tubes Matter in Superyachts

6082 is a medium‑strength, heat‑treatable aluminum alloy from the 6xxx series (Al‑Mg‑Si). In tube form, it offers an unusually efficient combination of:

- High specific strength (strength relative to weight)

- Excellent corrosion resistance in seawater

- Good weldability with marine‑qualified filler metals

- Predictable behavior under bending, machining, and forming

From a designer’s standpoint, 6082 tubes are a way to “move material where it matters” – placing strength along load paths without adding unnecessary solid mass. This is especially useful in long, slender structures like rails, masts, hardtop frames, ladders, and subsea piping where stiffness‑to‑weight is crucial.

Core Functions of 6082 Marine Tubes on a Superyacht

Think of 6082 tubes not as a single product, but as a structural language that repeats across the vessel:

Structural skeleton

- Hardtop supports, radar arches, and flybridge frames often rely on 6082 tubes to deliver rigidity with minimal added top weight. Less mass high up means lower center of gravity, better roll behavior, and improved comfort.

Load‑bearing handrails and guardrails

- Handrails and bulwark stanchions must carry human impact loads and meet classification rules for safety. 6082 in tempers such as T6 or T651 delivers sufficient yield strength while resisting denting and local buckling.

Deck outfit and support systems

- Davit arms, tender cradles, Bimini and awning frames, passerelle structures, and boarding ladders use tubular 6082 to keep components stiff and lightweight while sustaining cyclic loading and vibration from waves and machinery.

Fluid and systems routing

- When specified in suitable tempers and wall thicknesses, 6082 tubes can be used for low‑pressure marine piping, especially in non‑critical systems or as structural conduits and cable trays, where corrosion resistance and formability are important.

Under‑deck and interior frameworks

- Hidden structural frames for furniture, partitions, and ceiling systems benefit from 6082 tubes because they resist corrosion in humid, salt‑laden air while being easy to machine for brackets, inserts, and fasteners.

The common theme is this: 6082 tubes enable designers to build “light but honest” structures that are strong where needed, yet easy to fabricate and maintain.

Alloy Tempering: Choosing the Right Condition

6082 marine tubes are most commonly supplied in several heat‑treated tempers, each balancing strength and workability. From a practical design and fabrication standpoint, these are the tempers:

T6: Solution heat‑treated and artificially aged

- High strength, good for structural members and load‑bearing frames

- Lower formability; bending radii must be carefully controlled

- Typical for finished, dimensionally stable tubes in final assemblies

T651: Solution heat‑treated, stress‑relieved by stretching, then artificially aged

- Similar strength to T6, but with reduced residual stresses

- Better dimensional stability after machining or welding

- Preferred when precision machining, drilling, or slotting is expected

T5 / T52 (less common but important in formed parts)

- Cooled from elevated temperature shaping, then artificially aged

- Slightly lower strength than T6, better ductility

- Useful where more aggressive forming or bending is required before final installation

In practice, naval architects often specify T6 or T651 for primary structural tubes and selectively use softer tempers where extensive forming is needed. This temper strategy helps keep weld distortion, cracking, and spring‑back under control.

Mechanical and Dimensional Parameters

While exact values depend on standards and product forms, typical mechanical properties for 6082 in tube form (room temperature) are:

- Typical density: ~2.70 g/cm³

- Tensile strength (T6/T651): approx. 290–340 MPa

- Yield strength 0.2% (T6/T651): approx. 240–280 MPa

- Elongation: ~8–12% (depending on thickness and temper)

- Modulus of elasticity: ~70 GPa

- Shear modulus: ~26 GPa

Dimensional parameters in marine applications usually involve:

- Outer diameter range: from small tubes around 10–20 mm OD for fittings, up to 200+ mm for structural posts or system conduits

- Wall thickness: often from 1.5 mm to 10 mm depending on load, buckling risk, and classification rule requirements

- Lengths: commonly 6 m or 12 m stock lengths, with custom cut‑to‑size options for yard efficiency

For superyacht projects, the chosen tube geometry often comes from an iterative process: structural finite element analysis, classification rules (such as Lloyd’s Register, DNV, ABS, RINA), and fabrication constraints (bending radius, welding access, joint design).

Implementation Standards and Marine Compliance

To ensure traceability and performance, 6082 marine tubes are usually specified against recognized international standards such as:

- EN 573: Chemical composition of wrought aluminum alloys

- EN 755: Extruded aluminum and aluminum alloy products – Mechanical properties and tolerances for tubes

- EN 485: Mechanical properties for wrought aluminum sheets and plates (often referenced for comparable values)

- ASTM B221: Aluminum and aluminum‑alloy extruded bars, rods, wire, profiles, and tubes

In the marine context, classification societies may additionally require:

- Certified material test reports (MTRs) with heat number, chemistry, and mechanical test data

- Weld procedure qualification records (WPQR) for welding 6082 with appropriate filler alloys (commonly 5356 or 5183)

- Non‑destructive testing (NDT) on critical welded joints (e.g., ultrasonic, dye penetrant, radiography)

Proper alignment with these standards not only protects structural integrity but also streamlines approval with surveyors and flag authorities, avoiding late‑stage redesign or rework.

Chemical Composition of 6082 Alloy

The performance of 6082 in a marine environment comes directly from its carefully balanced chemistry. Typical composition ranges are:

| Element | Typical Content (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 0.60 – 1.20 |

| Silicon (Si) | 0.70 – 1.30 |

| Manganese (Mn) | 0.40 – 1.00 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.10 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

The Al‑Mg‑Si system forms strengthening Mg2Si precipitates during aging, giving 6082 its good strength, while manganese refines grain structure. Low copper content helps maintain excellent corrosion resistance in seawater compared to some higher‑strength 2xxx or 7xxx alloys, making 6082 a more reliable choice for exposed marine tubing.

Practical Benefits in the Shipyard

From a yard and refit perspective, 6082 marine aluminum tubes bring tangible advantages beyond the datasheet:

- Clean and predictable welding behavior with commonly used marine filler alloys

- Good response to anodizing and marine coatings, improving aesthetic finish and corrosion resistance

- Ease of machining for precise fit‑ups, threaded inserts, and custom brackets

- Lower fabrication weight reduces handling and installation time on board, especially for overhead and high‑level structures

By standardizing on 6082 tubes across multiple systems, yards can simplify stock management and ensure consistent welding and forming procedures, improving quality and repeatability from one project to the next.

A Design‑Led View of 6082 Marine Tubes

For high‑end superyachts, every kilogram and every joint counts. 6082 marine aluminum tubes help designers navigate a narrow space where aesthetics, performance, and reliability must all coexist.

They provide:

- Structural confidence: enough strength and stiffness for demanding load cases

- Corrosion resilience: long‑term durability in saltwater and humid atmospheres

- Fabrication freedom: the ability to bend, weld, machine, and finish without exotic processes

When specified in the right temper, to the right standard, and with the right geometry, 6082 tubes quietly underpin the luxury you see on deck – enabling elegant lines, thin profiles, and unobtrusive structures that still meet the strict expectations of class, owners, and captains.

For naval architects, shipyards, and refit specialists, these details is the to turning a simple alloy designation – 6082 – into a reliable structural strategy for modern superyacht construction.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

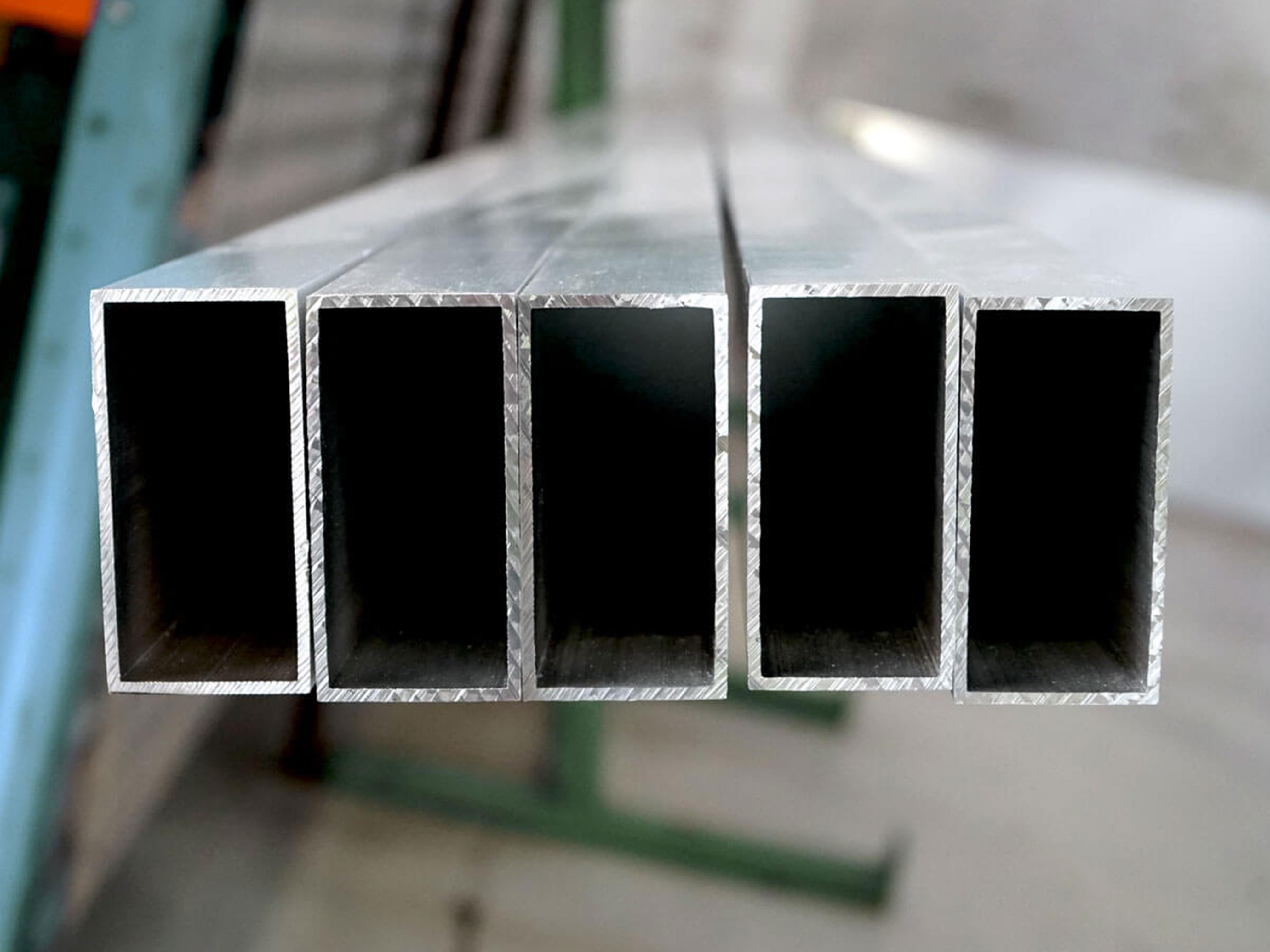

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View Details6082 Marine Aluminum Tubes for Superyacht Construction

6082 Marine Aluminum Tubes for Superyacht ConstructionA Technical Deep Dive from a Designer’s Perspective In modern superyacht construction, 6082 marine aluminum tubes occupy a quiet but critical role.

View Details6082 Marine Aluminum Tubes for Saltwater Tolerant Marine Parts

6082 Marine Aluminum Tubes for Saltwater‑Tolerant Marine PartsA structural engineer’s perspective on choosing the “workhorse” alloy for modern boats and offshore equipmentWhen designers talk about marine alloys for direct saltwater exposure, 6082.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details

Leave a Message