Marine Aluminum Heat Sink Profile for High Performance Heat Transfer in Coastal Equipment

In coastal and marine environments, electronic and mechanical equipment face rigorous demands due to harsh conditions such as saltwater exposure, high humidity, and temperature fluctuations. Efficient thermal management becomes crucial to ensure longevity and performance. Here, the Marine Aluminum Heat Sink Profile serves as an indispensable component by providing optimized heat dissipation, unmatched corrosion resistance, and structural stability.

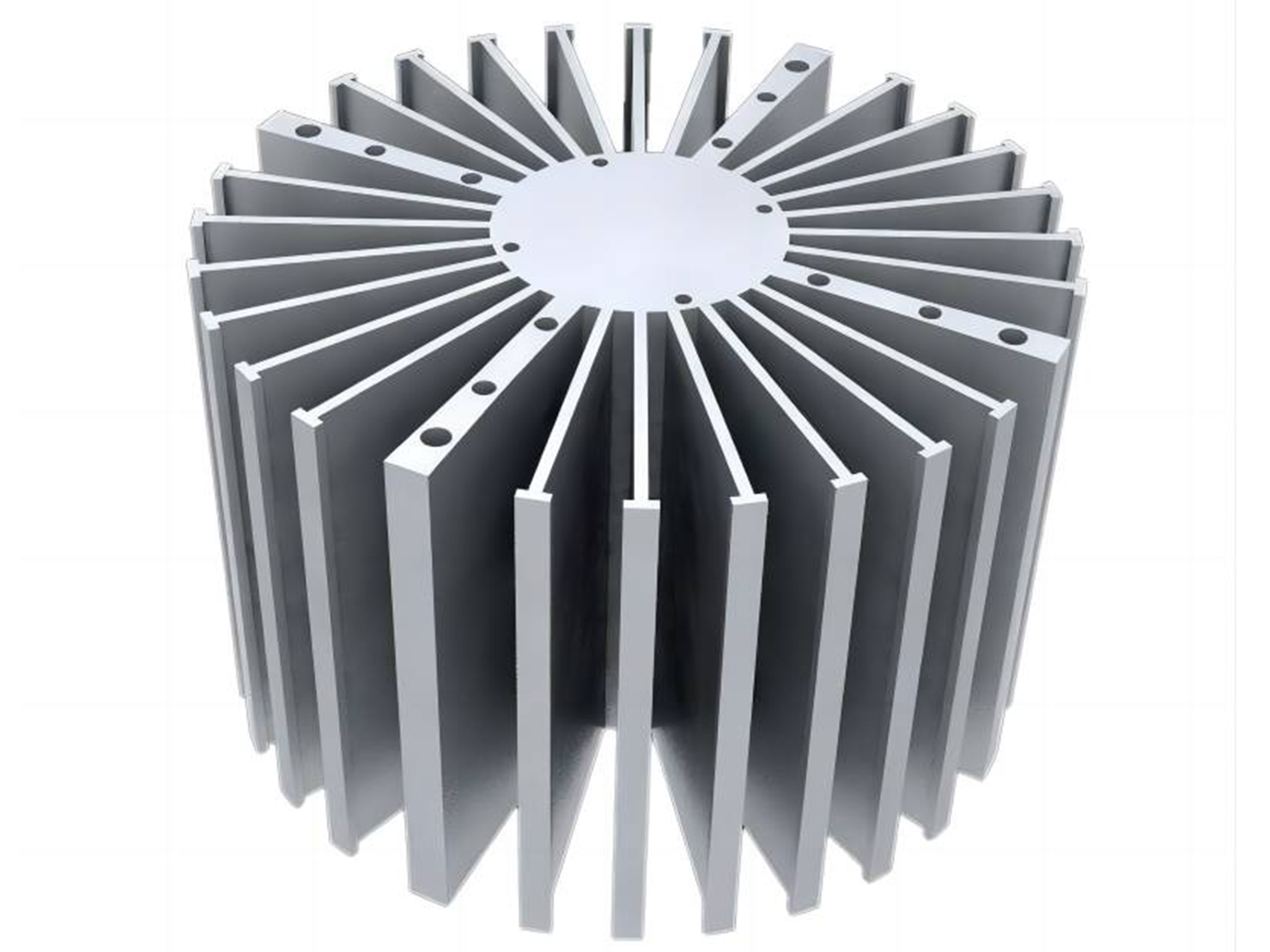

A Marine Aluminum Heat Sink Profile is a specially designed aluminum extrusion optimized for heat dissipation in exposed or harctic environments like coastal or offshore applications. Manufactured using marine-grade aluminum alloys and engineered geometric profiles, these heat sinks maximize surface area for enhanced convective cooling while resisting environmental degradation. They are widely applied in coastal radar systems, navigation aids, marine communication devices, and power conversion units.

Features and Benefits

| Feature | Benefit |

|---|---|

| High Thermal Conductivity Alloy Options | Ensures rapid heat dissipation for reliable equipment function. |

| Superior Corrosion Resistance | Specifically alloys like AA6061–T6 and AA5052 ensure long-term durability against salt spray and humidity. |

| Custom Profile Geometry | Fine fin spacing, optimized surface area tailored to specific heat loads maximizes cooling efficiency. |

| Lightweight Yet Robust | Aluminum’s high strength-to-weight ratio reduces structural load without compromising strength. |

| Compatibility with Marine-Grade Surface Treatments | Can be anodized or powder-coated to further enhance corrosion protection and aesthetical qualities. |

Alloy and Temper Specifications

Metal alloy selection ensures that mechanical and corrosion properties fulfill marine environment demands. Some standard alloys used include:

Working with marine aluminum alloys in coastal environments presents unique challenges beyond standard heat sink design. The constant exposure to salt spray dramatically accelerates corrosion, demanding careful material selection and surface treatments. We've found that 5086 and 6061 alloys, while possessing good heat transfer properties, require meticulous anodizing or powder coating to withstand the aggressive marine atmosphere. Furthermore, the design itself must account for potential crevice corrosion. Complex geometries with numerous small recesses can trap moisture and accelerate degradation. Thus, a simpler, more robust profile with larger, open channels is often preferable, even if it marginally compromises heat transfer efficiency for the sake of longevity and maintainability. We've seen firsthand the cost savings of prioritizing corrosion resistance over minor performance gains in the long run.

Our experience with coastal equipment heat sinks also underscores the importance of considering biofouling. Organisms attaching to the fins can significantly impede heat transfer, necessitating regular cleaning or the incorporation of antifouling coatings into the design. This is especially crucial for applications like sonar housings or radar systems where efficient heat dissipation is paramount for reliable operation. We've recently explored integrating self-cleaning surfaces, leveraging hydrophobic coatings or textured profiles to minimize biofouling adherence. Ultimately, the ideal marine aluminum heat sink profile for coastal equipment represents a carefully balanced optimization between thermal performance, corrosion resistance, and biofouling mitigation, reflecting the harsh realities of the marine environment.

| Alloy | Temper | Chemical Composition (%) | Typical Mechanical Properties | Application Considerations |

|---|---|---|---|---|

| AA6061 (Marine Grade) | T6 | Si (0.4-0.8), Mg (0.8-1.2), Fe (<0.7) | Tensile Strength: 290 MPa, Yield Strength: 240 MPa | |

| Good combination of strength, corrosion resistance, weldability | ||||

| AA5052 | H32 / H34 | Mg (2.2-2.8), Cr (0.15-0.35), Fe (<0.4) | Tensile Strength: 215 MPa, Yield Strength: 145 MPa | |

| Excellent corrosion resistance, especially good for uncoated conditions | ||||

| AA6082 | T6 | Si (0.7-1.3), Mg (0.6-1.2), Fe (<0.5) | Tensile Strength: 310 MPa, Yield Strength: 260 MPa | |

| Structural robustness with good corrosion/chip resistance |

Physical and Thermal Properties

| Parameter | Value |

|---|---|

| Density | ~2.70 g/cm³ |

| Thermal Conductivity | 167-180 W/m·K (depending on alloy and temper) |

| Melting Point | ~580 - 650 °C |

| Coefficient of Thermal Expansion | ~23 x 10^-6 /°C |

Implementation and Industry Standards

Marine Aluminum Heat Sink Profiles must comply with rigorous requirements set forth by both international and industry-recognized marine standards:

- ISO 9227: Corrosion testing — Neutral Salt Spray (NSS) Test for marine aluminum alloys.

- AA Metallic Aluminum Standards: per Aluminum Association (AA) specifications.

- ASTM B221/B221M: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- MIL-A-8625: Specifications for anodic coatings on aluminum for marine durability enhancement.

Recommended Finishing Processes

- Anodizing (Type II & III): Guarantees a hard oxide layer to resist saltwater pitting, abrasion, and improves aesthetics.

- Powder Coating: Applied over anodized or bare surfaces; provides additional UV/abrasion resistance with diverse color options.

- Marine-Grade Sealants and Epoxy Coatings: To fill imperfections and prevent micro-permeation of corrosive agents.

Design Considerations for Optimal Heat Transfer

- Fin Density and Thickness Optimization: Tailoring fin pitch to balance airflow and minimizing dust/debris buildup in marine environments.

- Surface Treatments: Combining anodizing with thermal interface materials (TIM) further enhances heat dissipation efficiency.

- Mounting Compatibility: Provision of standardized slots or mounting holes to seamlessly attach equipment with minimal thermal resistance.

Real World Applications

- Coastal Telecommunication Towers: Protection of RF amplifiers with compact and highly conductive heat sinks.

- Marine Navigation and Radar Systems: Enhanced thermal performance drives system reliability especially in off-shore wind farms and ships.

- Power Electronics Enclosures: Traction systems in electric boats use marine aluminum heat sinks to prevent thermal runaway.

- Lighting Fixtures: Aluminum profiles act as both mechanical frames and heat dissipators for vessel and pier lighting compliant with maritime humidity.

For any coastal or marine equipment requiring robust thermal management, Marine Aluminum Heat Sink Profiles present a perfect convergence of performance, durability, and cost-effectiveness. They utilize optimized marine grade alloys such as AA6061–T6 and AA5052, comply with international standards, and resist corrosion, enabling steady device operation under challenging environmental conditions.

Contact Us

Contact our engineering team for custom prototype development or bulk orders designed specially for your coastal equipment project. Let our Marine Aluminum Heat Sink Profiles improve your heat management system’s resilience and efficiency.

Keywords: Marine aluminum heat sink, corrosion resistant heat sink, marine grade aluminum alloy, coastal environment heat dissipation, high thermal conductivity aluminum profile.

Related Products

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsRelated Blog

6061 Marine Aluminum Customized Shapes for Offshore Engineering Projects

In the fast-evolving world of offshore engineering, the demand for materials that ensure strength, corrosion resistance, and versatility has never been higher. Among various options.

View Details6061 Marine Aluminum Customized Shapes for High Performance Offshore Vessel Design

Explore the advantages of 6061 Marine Aluminum customized shapes engineered for high performance offshore vessel design. detailed specifications, temper conditions, mechanical properties, and corrosion resistance features tailored for marine environments.

View DetailsMarine Aluminum Heat Sink Profile for High Performance Heat Transfer in Coastal Equipment

High-performance Marine Aluminum Heat Sink Profile specially engineered for coastal equipment, offering superior corrosion resistance, thermal conductivity, and durability to ensure optimal heat transfer even in harsh marine environments.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View Details6061 Marine Aluminum Heat Sink Profile for Custom Boat and Ship Engine Cooling

Explore the superior cooling efficiency of 6061 Marine Aluminum Heat Sink Profiles, engineered for custom boat and ship engines. detailed specifications, temper types, chemical properties, standards compliance, and advanced corrosion resistance features o

View DetailsMarine Aluminum Heat Sink Profile for Lightweight Boat Engine Cooling Systems

Marine Aluminum Heat Sink Profile for Lightweight Boat Engine Cooling Systems: Excellence in Functionality and Technical PrecisionIn the evolving sphere of marine engineering, optimizing boat engine cooling systems for lightness, durability.

View Details

Leave a Message