5083 Marine Aluminum Fencing and Railings for Durable Coastal Property Barriers

When a coastal property owner chooses fencing and railings, the conversation usually revolves around style, code compliance, and budget. The ocean, however, has its own priorities: salt, moisture, wind, and UV radiation. This is where 5083 marine aluminum steps in—not as a decorative afterthought, but as a structural, corrosion‑resistant system designed from the same logic as boat hulls and offshore platforms.

Below is a concise yet technically rich overview of 5083 Marine aluminum fencing and railings as long‑term coastal barriers.

Why 5083 Marine Aluminum Instead of Regular “Outdoor” Metals

Most outdoor metals are designed to cope with rain. Coastal metals must cope with salt. Chloride ions in sea air penetrate oxide films, pit steel, and even attack many common aluminum alloys.

Alloy 5083 belongs to the 5xxx series (Al‑Mg), originally tailored for marine structures. Its defining feature is a relatively high magnesium content combined with controlled traces of manganese and chromium. This combination produces:

- Exceptional resistance to seawater and salt‑laden air

- A self‑healing aluminum oxide layer that regenerates if lightly scratched

- High strength without heavy dependence on heat treatment

In practical terms, a 5083 fence panel or balcony rail can sit a few meters from breaking waves and retain surface integrity for years with minimal maintenance, provided it is properly finished and installed.

Functional Roles: Beyond Just a Perimeter

From a functional perspective, 5083 Marine aluminum fencing and railings act as:

- Safety barriers on coastal balconies, decks, piers, marinas, and boardwalks

- Property boundaries resistant to wind‑driven sand and salt spray

- Fall‑prevention systems on sea walls, revetments, and promenades

- Access controls around pools, private jetties, and harbor infrastructure

The same alloy that withstands continuous contact with seawater in ship hulls now works in a less obvious way: as a structural “skin” that surrounds, protects, and defines coastal spaces.

Architects often specify 5083 in slim profiles for minimal visual obstruction of ocean views; engineers value its predictable mechanical behavior under wind load and crowd load.

Technical Parameters for Coastal Fencing and Railings

Although 5083 is versatile, its performance depends heavily on temper (processing condition) and profile design. Some representative parameters:

Common tempers for fencing and railing profiles

- H111: Slightly strain‑hardened; retains good ductility and weldability

- H116: Strain‑hardened and stabilized; optimized for marine corrosion resistance

- H321: Strain‑hardened and stabilized; controlled mechanical properties and good stress‑corrosion resistance

Typical mechanical properties (approximate, for flat products):

- Yield strength:

- H111: ~125–145 MPa

- H116 / H321: ~215–240 MPa

- Ultimate tensile strength:

- H111: ~270–320 MPa

- H116 / H321: ~300–340 MPa

- Elongation (A50):

- H111: ~16–20 %

- H116 / H321: ~10–14 %

For vertical posts resisting wind and impact on coastal sites, the higher‑strength tempers H116 or H321 are often chosen, especially for tall or widely spaced posts. Handrails that require tighter forming may use H111 in curved segments to maintain bendability.

Density and weight advantage

- Density: ~2.66 g/cm³

- Weight savings compared to stainless steel: often 30–35 % lighter for comparable stiffness, reducing foundation loads and easing installation on elevated decks or retrofits.

Chemical Composition of 5083 Marine Aluminum

5083 is an aluminum‑magnesium alloy with carefully controlled additions that influence corrosion behavior and strength. A typical composition range (mass %):

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Other (each) | ≤ 0.05 |

| Other (total) | ≤ 0.15 |

Magnesium is the main strengthening and corrosion‑resisting element in seawater. Manganese and chromium refine grain structure and improve resistance to stress‑corrosion cracking. Tight control of copper content limits galvanic susceptibility.

From Boat Hull Logic to Balcony Rail Logic

The same logic that governs hull plating applies to a coastal guardrail system:

- Uniform, stable temper to avoid localized weakness

- Weldable joints that do not become the first point of corrosion

- Surface finishes that complement the natural oxide film

Shipbuilders rely on 5083 for transverse frames, hull plating, and superstructures because it survives cyclic wave loading and saltwater immersion. In a railing, those loads become wind suction, impact loads from people leaning, and repeated thermal expansion and contraction. The alloy’s fatigue resistance and ductility matter just as much in a hotel balcony as in a catamaran hull.

Implementation Standards and Design Considerations

Codes vary by region, but designing with 5083 marine aluminum usually touches three main groups of standards:

Structural and safety standards

- Building codes and load standards (such as IBC, Eurocode, or equivalent local codes) define minimum horizontal load on railings, post spacing, and height requirements. 5083’s strength-to-weight ratio enables slender posts and top rails that still meet these loads.

Material and marine standards

- EN 485 / EN 573 or ASTM B209 / B928 for plate and sheet

- Marine‑grade tempers (H116, H321) typically meet or exceed marine service expectations, especially near splash zones.

Surface treatment and durability guidelines

- Anodizing standards (such as ISO/Qualanod or equivalent) and powder‑coating standards for coating thickness, adhesion, and UV resistance ensure the aesthetic life matches the structural life.

Designers often pair 5083 frames with stainless fasteners that are carefully isolated using nylon or polymer bushings and washers to avoid galvanic corrosion, especially in direct splash zones.

Surface Finishes: Turning Corrosion Resistance into Aesthetics

Left bare, 5083 will form a dull, stable oxide in coastal air. Many coastal projects, however, require a higher aesthetic standard and additional surface protection:

Anodizing

Thick anodized layers (for example, 20–25 μm) create a dense barrier that enhances natural corrosion resistance. The micro‑porous surface can be sealed for stain resistance. Anodized 5083 retains a metallic look that suits marinas and modern beachfront designs.Marine‑grade powder coating

A properly pre‑treated and powder‑coated surface provides color, texture, and further protection. When applied over 5083, powder coatings experience less under‑film corrosion compared with many non‑marine alloys, particularly if edges are well radiused and welds are properly ground and pre‑treated.

Practical Applications in Coastal Projects

5083 Marine aluminum fencing and railings appear in several distinct roles:

- Marina and harbor rail systems around piers, gangways, and dock perimeters

- Elevated seaside decks, hotel balconies, and roof terraces exposed to onshore winds

- Pool and beach access barriers where chlorinated water and sea spray coexist

- Property boundary fences along dunes, cliffs, or seawalls where conventional steel rusts rapidly

- Public seaside promenades where maintenance windows are short and crowd loads are high

In many cases, system designers use hollow extrusions for posts and rails with internal reinforcement where needed, taking advantage of 5083’s weldability to create continuous frames that distribute load efficiently.

Installation Conditions That Preserve Durability

The alloy’s chemistry and temper are only part of the story; site practice makes or breaks long‑term durability:

Drainage and detailing

Profiles are designed with internal drainage paths and open ends or weep holes to prevent saltwater accumulation. Standing brine is an enemy even for marine alloys.Isolation from dissimilar metals

Contact with carbon steel or non‑marine stainless can create galvanic cells. Plastic spacers, gaskets, and compatible sealants form a barrier at joints and brackets.Controlled welding and fabrication

Using 5xxx‑series filler metals (such as 5183 or 5356) preserves corrosion resistance at welds. Post‑weld cleaning and passivation steps help the oxide layer reform uniformly.

Implemented correctly, the installed system behaves as a continuous marine barrier, not a patchwork of different metals fighting electrochemistry.

A Coastal Barrier Designed Like a Vessel

Thinking of 5083 Marine aluminum fencing and railings as “miniature hulls” surrounding your property is a useful mental model. They are light but strong, exposed but protected, and engineered to coexist with salt rather than constantly battle it.

For coastal developers, hotel owners, marina operators, and private homeowners, this alloy offers a durable, low‑maintenance way to secure and define sea‑exposed spaces while keeping structures lean and visually unobtrusive. When correctly specified in the right temper, finished to marine standards, and detailed with galvanic isolation in mind, 5083 marine aluminum becomes less a decorative accessory and more a quietly resilient coastal infrastructure.

Related Products

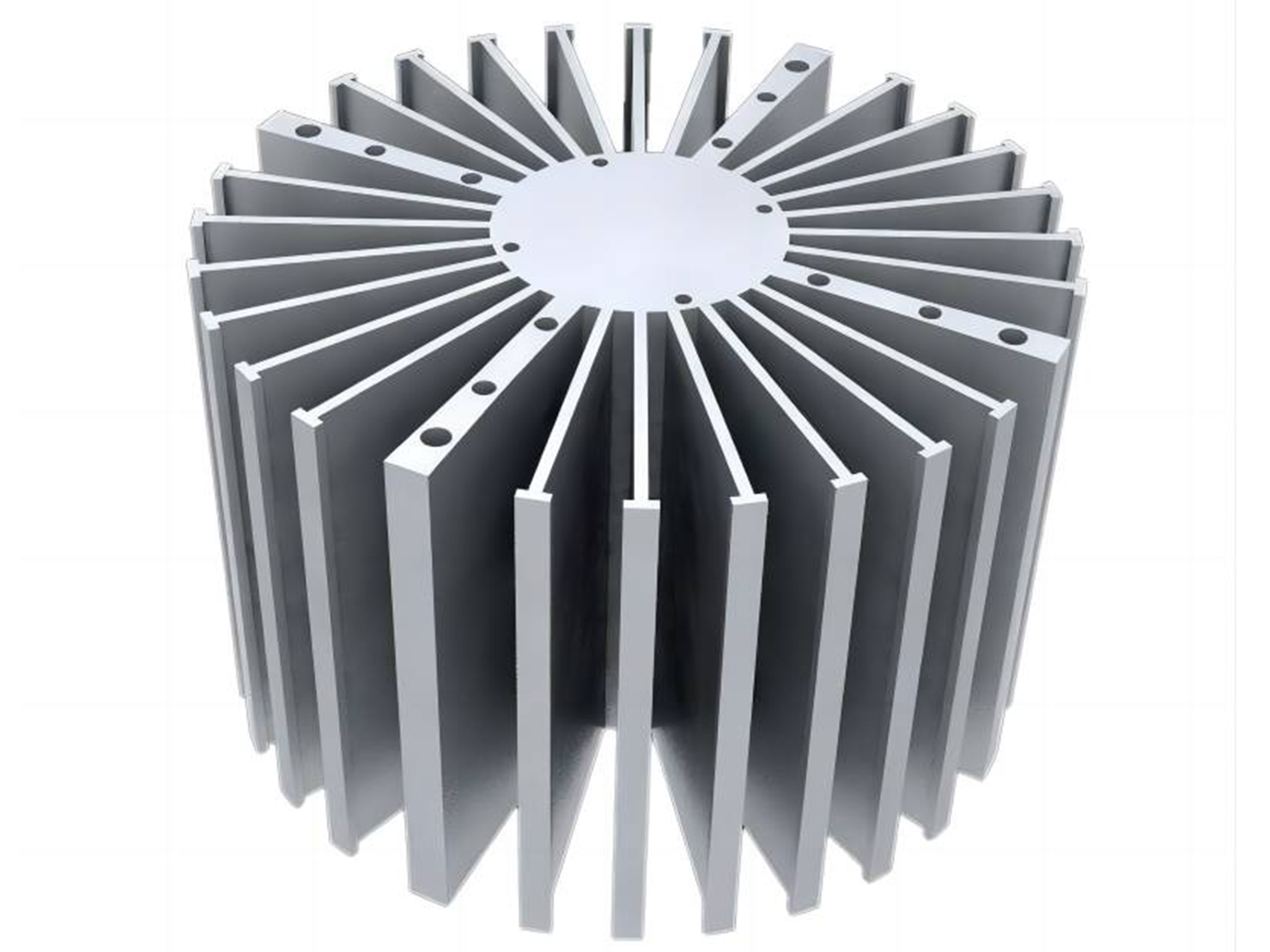

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Fencing and Railings for Durable Coastal Property Barriers

When a coastal property owner chooses fencing and railings, the conversation usually revolves around style, code compliance, and budget. The ocean, however, has its own priorities: salt, moisture, wind, and UV radiation.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details5083 Marine Aluminum Fencing and Railings for Lightweight Offshore Guardrail Systems

When it comes to offshore guardrail systems, ensuring safety, durability, and corrosion resistance are paramount. 5083 Marine Aluminum has emerged as an excellent material choice for fencing and railings in marine environments.

View Details5083 Marine Aluminum Customized Shapes for Custom Ship Hull Construction

In the realm of marine engineering, the construction of ship hulls strikes at the foundation of naval architecture and ship integrity. Among the variety of materials available, instead, one alloy has repeatedly distinguished itself as the go-to choice.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Fencing and Railings for Custom Marine Infrastructure Barriers

When it comes to building durable, high-performance marine infrastructure barriers such as fencing and railings, 5083 Marine Aluminum stands out as an industry-leading material.

View Details

Leave a Message