Marine 5059 Aluminum Plate is a high-performance aluminum-magnesium alloy plate that offers superior strength and exceptional corrosion resistance, making it an ideal choice for demanding marine and offshore applications. As a premium member of the 5xxx aluminum alloy series, 5059 delivers enhanced mechanical properties compared to traditional marine alloys while maintaining excellent weldability and formability. This combination makes it increasingly popular in shipbuilding, offshore platform construction, high-speed vessels, and other structural marine projects.

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance. Unlike some 5xxx alloys, 5059 is strain-hardened and strain-age hardened, which results in outstanding tensile strength and yield strength, positioning it between 5083 and 5086 in performance.

In addition to excellent seawater corrosion resistance, 5059 aluminum exhibits improved resistance to stress corrosion cracking, making it safer and more reliable in structural marine environments where cyclic stresses and harsh conditions prevail.

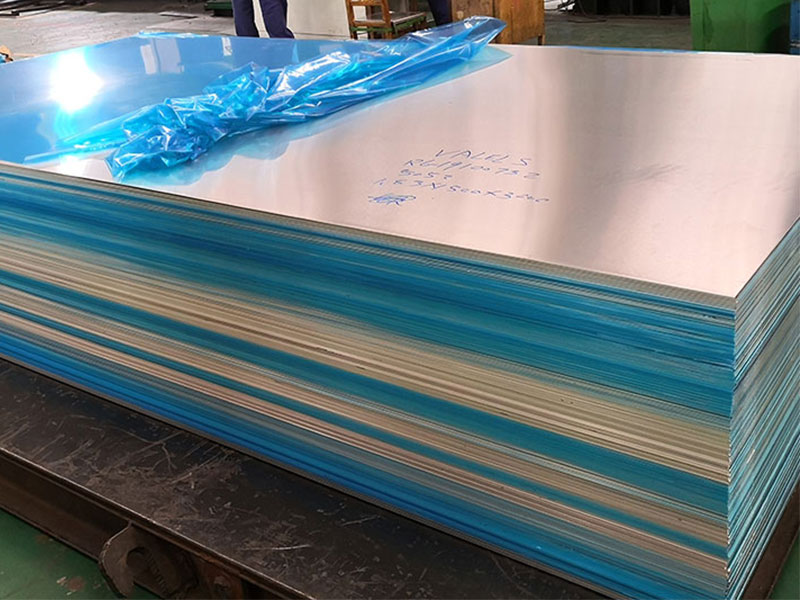

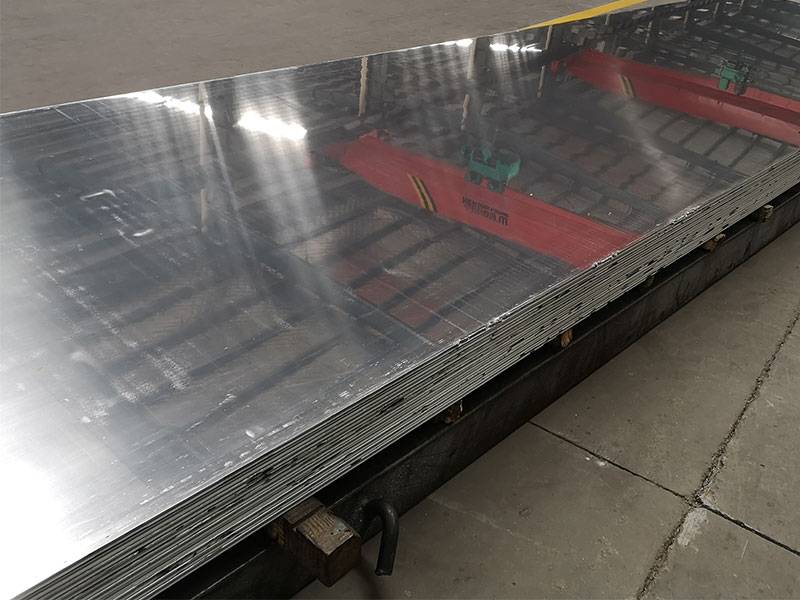

Manufactured by controlled hot rolling and cold working, 5059 marine plates maintain superior dimensional accuracy, surface finish, and mechanical uniformity across the sheet.

Chemical Composition

The chemistry of Marine 5059 Aluminum Plate plays a critical role in its performance characteristics:

| Element | Typical Range (%) |

|---|---|

| Magnesium (Mg) | 5.8 – 6.4 |

| Chromium (Cr) | 0.35 – 0.55 |

| Manganese (Mn) | 0.2 – 0.7 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5059 Aluminum Plate is available in several strain-hardened tempers, with H131, H136, and H321 being most common for marine structural use. Below is a summary of typical mechanical properties:

| Property | 5059-H131 | 5059-H136 | 5059-H321 |

|---|---|---|---|

| Tensile Strength (MPa) | 380 – 430 | 400 – 460 | 370 – 420 |

| Yield Strength (MPa) | 240 – 300 | 260 – 310 | 230 – 290 |

| Elongation (%) | 8 – 12 | 7 – 10 | 9 – 14 |

| Brinell Hardness (HB) | 110 – 130 | 115 – 135 | 105 – 125 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 |

Physical and Thermal Properties

Density: Approximately 2.66 g/cm³, offering significant weight savings versus steel alternatives.

Thermal Conductivity: ~130 W/m·K, beneficial for moderate heat dissipation needs on marine vessels.

Melting Point: 570 to 640 °C, imparting thermal stability suitable for marine environments.

Electrical Conductivity: Roughly 28–30% IACS, effective for grounding and electrical applications on ships.

Manufacturing Process

Marine 5059 Aluminum Plates are produced through:

Hot Rolling: Controlled hot rolling produces heavy gauge plates with uniform thickness and strength.

Cold Working and Strain Aging: Enhances mechanical strength while maintaining ductility and toughness.

Surface Preparation: Standard mill finish supplied; anodizing or coatings are available for additional corrosion protection or aesthetics.

Post-processing: Plates can be cut, machined, formed, and welded using industry standard marine fabrication techniques.

Typical Marine Applications

Marine 5059 Aluminum Plate’s excellent strength and corrosion resistance make it suitable for:

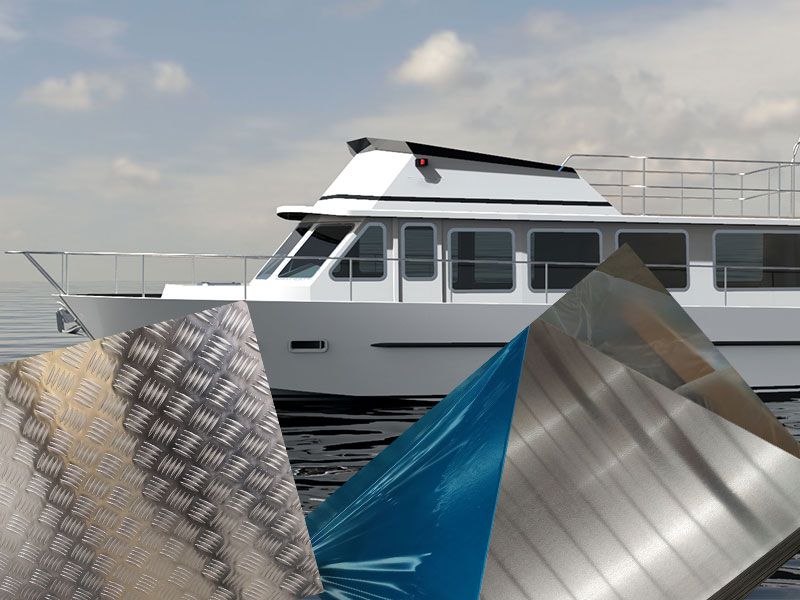

High-Speed Vessels and Naval Ships: Hull plating, decks, and structural members where high strength and reduced weight are critical.

Offshore Oil and Gas Platforms: Heavy structural panels, walkways, and protective housings.

Commercial Shipping: Superstructure components, reinforcement plates, and fuel or ballast tanks.

Specialized Marine Equipment: Crane bases, support frameworks, and marine transportation containers.

Recreational Yachts and Ferries: Lightweight yet strong panels for decks and cabins enhancing performance and safety.

Advantages of Marine 5059 Aluminum Plate

Superior Strength: Higher tensile and yield strength than many conventional marine aluminum alloys.

Exceptional Corrosion Resistance: Versatile protection against seawater and marine atmospheric conditions, including resistance to stress corrosion cracking.

Good Weldability: Can be welded with TIG, MIG, or resistance methods with appropriate filler wire and procedures.

Excellent Fatigue Resistance: Suitable for high-cycle loading typical in marine structural applications.

Good Formability: Can be formed and bent with standard procedures without cracking or losing strength.

Lightweight: Weight savings compared to steel reduce fuel consumption and increase payload capacity.

Maintenance and Durability

To ensure optimal life span and sustained performance:

Regular Rinsing: Clean with freshwater to remove salts and marine residue.

Avoid Harsh Abrasives: Use soft brushes and mild detergents to prevent superficial damage.

Inspection: Periodically examine for signs of mechanical damage or corrosion, especially near welds.

Protective Coatings: Anodizing or marine-grade paints can complement the natural corrosion resistance in highly aggressive environments.

Welding Repairs: Employ qualified welders and suitable filler materials to maintain corrosion resistance and strength.

Marine 5059 Aluminum Plate stands out as a high-strength, corrosion-resistant, and highly durable material designed to meet the rigorous demands of modern marine and offshore structures. Its advanced alloy chemistry and physical properties make it especially valuable for structural components requiring significant load-bearing capacity and longevity in seawater environments.

For detailed technical advice, tailored specifications, or pricing information, please contact our marine metals experts who are ready to assist you with your project requirements.