Marine Heavy Duty Aluminum Plates Sheets are specially engineered aluminum alloy materials designed to fulfill the demanding structural and operational requirements of marine vessels, offshore platforms, and coastal infrastructure. Combining the inherent advantages of aluminum—lightweight, corrosion resistance, and strength—with increased thickness and enhanced mechanical properties, these heavy duty aluminum plates and sheets provide reliable, long-lasting performance in harsh marine environments.

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383. They boast superior tensile strength, excellent corrosion resistance, and good weldability—all critical for structural integrity and safety in aggressive saltwater conditions.

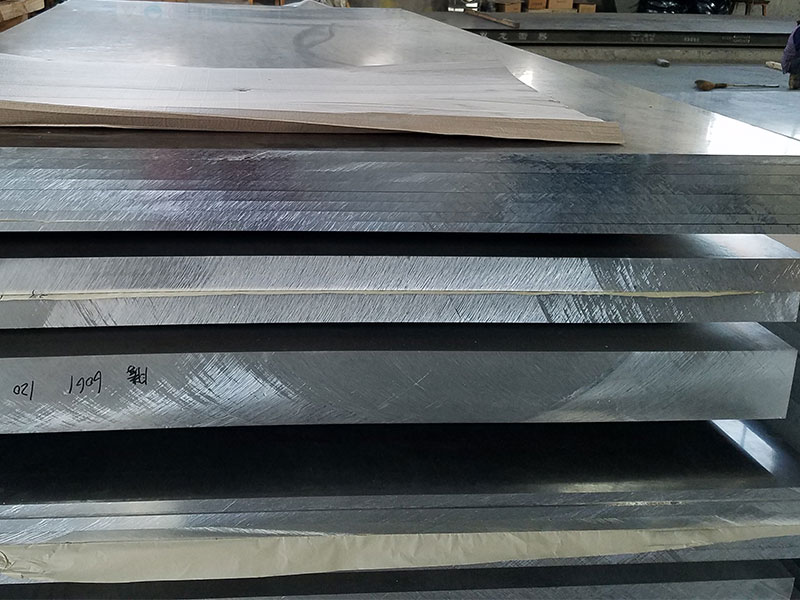

These plates are fabricated through advanced hot rolling and finishing processes to achieve uniform thickness, high flatness, and pristine surface quality. Their heavy duty nature stems from thicker dimensions — typically ranging from 6 mm up to 150 mm or more — providing robustness for load-bearing and impact resistance applications.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminum Alloy | Typically 5xxx series alloys (e.g., 5083, 5086) known for excellent seawater corrosion resistance | Superior longevity in marine environments |

| Heavy Gauge Thickness | Thickness from 6 mm to 150 mm+ allowing use in demanding structural applications | High structural strength and durability |

| High Tensile and Yield Strength | Enhanced strength properties suitable for load-bearing ship components and offshore structures | Ensures safety and reliability under mechanical stress |

| Excellent Weldability | Compatible with common welding techniques such as TIG, MIG, and resistance welding | Facilitates fabrication, assembly, and repairs |

| Good Formability and Machinability | Despite heavy thickness, alloy maintains good workability for shaping and machining | Allows manufacturing of complex marine components |

| Corrosion and Pitting Resistance | Superior resistance to seawater corrosion, including pitting and crevice corrosion | Reduced maintenance and extended operational life |

| Lightweight Compared to Steel | Approximately one-third the weight of comparable steel plates | Improves vessel fuel efficiency and overall payload capacity |

Chemical Composition

Marine heavy duty aluminum plates typically utilize alloys within the 5xxx series optimized for marine conditions. Typical chemical composition for common alloys is as follows:

| Element | 5083 (%) | 5086 (%) | 5059 (%) | 5383 (%) |

|---|---|---|---|---|

| Magnesium (Mg) | 4.0 – 4.9 | 4.0 – 4.9 | 5.8 – 6.4 | 4.5 – 5.5 |

| Manganese (Mn) | 0.4 – 1.0 | 0.2 – 0.7 | 0.2 – 0.7 | 0.2 – 0.7 |

| Chromium (Cr) | 0.05 – 0.25 | 0.05 – 0.25 | 0.35 – 0.55 | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.4 | ≤ 0.35 | ≤ 0.3 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.15 | ≤ 0.1 | ≤ 0.1 |

| Aluminum (Al) | Balance | Balance | Balance | Balance |

Mechanical Properties

Mechanical properties vary by alloy and temper but generally provide excellent strength for heavy duty applications. Example values for typical tempers:

| Property | 5083-H321 | 5086-H32 | 5059-H131 | 5383-H116 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 275 – 350 | 380 – 430 | 320 – 380 |

| Yield Strength (MPa) | 145 – 215 | 145 – 230 | 240 – 300 | 205 – 290 |

| Elongation (%) | 10 – 18 | 12 – 18 | 8 – 12 | 10 – 13 |

| Brinell Hardness (HB) | 75 – 95 | 75 – 95 | 110 – 130 | 85 – 105 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 | 2.66 |

Typical Applications

Shipbuilding: Hull plating, decks, bulkheads, ship structural frameworks

Offshore Platforms: Structural panels, load-bearing supports, walkways

Marine Infrastructure: Bridges, piers, docks, and cranes

Naval Vessels: Armored plating, superstructure components requiring enhanced strength

Custom Marine Fabrication: Tanks, containers, and marine vehicle parts

High-Performance Yachts and Ferries: Lightweight structural components balancing strength and weight

Manufacturing and Fabrication

Manufacturing of Marine Heavy Duty Aluminum Plates Sheets includes:

Hot Rolling: To achieve heavy gauge plates with uniform properties.

Surface Finishing: Mill finish, polishing, or anodizing to enhance corrosion resistance and appearance.

Fabrication capabilities include:

Welding: Approved TIG, MIG, and resistance welding to maintain corrosion resistance and strength.

Cutting: Plasma, laser, water jet, or mechanical cutting for precise dimensions.

Forming: Bending, rolling, and shaping with attention to alloy-specific requirements due to thickness.

Machining: Drilling, milling, and threading as required for custom fittings and components.

Corrosion Resistance and Maintenance

Heavy duty marine aluminum plates are inherently corrosion-resistant due to the natural formation of a protective oxide film. This is reinforced by the alloying elements magnesium and chromium that inhibit pitting and stress corrosion.

Maintenance Recommendations:

Regular cleaning with fresh water to remove salt and contaminants.

Avoid chemical exposure to strong acids or alkaline substances.

Visual inspections for mechanical damage, especially in welded or fastened areas.

These plates require significantly less maintenance than steel equivalents, making them cost-effective over their lifecycle.

Marine Heavy Duty Aluminum Plates Sheets combine the lightweight benefits of aluminum with substantial thickness, superior corrosion resistance, and high strength tailored for structural marine and offshore applications. They offer marine engineers and fabricators a robust material solution capable of performance under demanding mechanical loads and exposure to aggressive seawater conditions. With excellent weldability and fabrication versatility, these heavy duty plates are essential for building reliable, efficient, and long-lasting marine vessels and infrastructure.

Ordering Information

Customers can specify:

Alloy type (e.g., 5083, 5086, 5059, 5383)

Thickness (custom heavy gauge options from 6 mm to 150 mm+)

Sheet dimensions (width and length)

Temper designation and mechanical property requirements

Surface finish preferences (mill, anodized, coated)

Custom cutting or fabrication services

Contact our sales engineering team for detailed specifications, competitive quotations, and technical support.