Marine 5052 Aluminum Plate is a high-quality alloy plate specifically engineered for marine and coastal applications requiring excellent corrosion resistance, good mechanical strength, and outstanding formability. Belonging to the 5xxx series aluminum-magnesium alloys, 5052 aluminum plate offers superior performance in saltwater environments, making it a trusted material choice for shipbuilders, offshore engineers, and marine fabricators looking for a balance between strength, durability, and ease of fabrication.

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres. Its magnesium content (approximately 2.2% to 2.8%) greatly enhances its ability to withstand marine environments, while also contributing to its excellent fatigue and wear resistance. The alloy's excellent formability and weldability allow it to meet complex design demands common in marine structures and vessels.

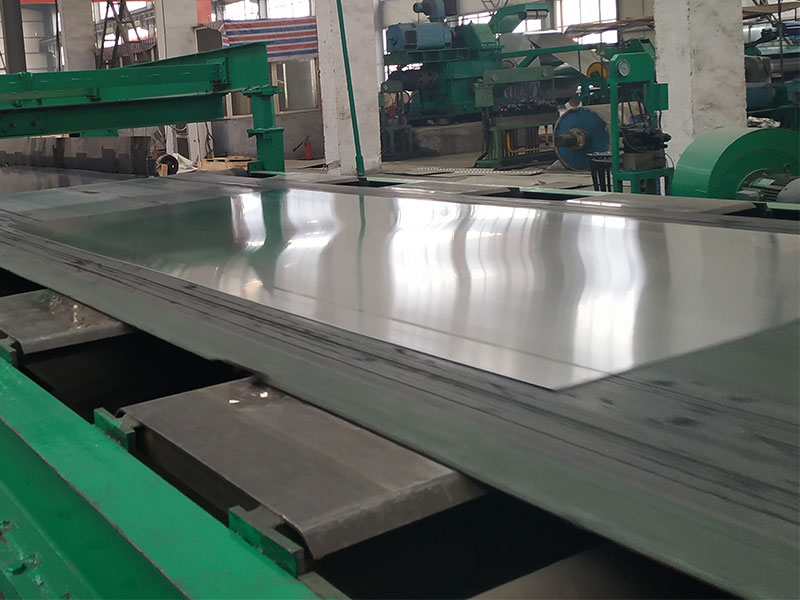

Manufactured through advanced hot rolling processes, 5052 aluminum plates maintain consistent dimensional tolerances, superior surface finish, and the mechanical consistency required for marine-grade materials.

Chemical Composition

The alloying elements of Marine 5052 Aluminum Plate contribute directly to its corrosion resistance, strength, and fabricability:

| Element | Typical Content (%) |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.03 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5052 Aluminum Plate is available in several tempers; H32 and H34 are most common in marine applications due to their excellent balance of strength and flexibility.

| Property | 5052-H32 | 5052-H34 |

|---|---|---|

| Tensile Strength (MPa) | 228 – 271 | 229 – 272 |

| Yield Strength (MPa) | 103 – 138 | 117 – 155 |

| Elongation (%) | 10 – 15 | 8 – 10 |

| Hardness (Brinell) | 60 – 75 | 70 – 80 |

| Density (g/cm³) | 2.68 | 2.68 |

Physical Properties

Density: Approximately 2.68 g/cm³, significantly lighter than steel.

Thermal Conductivity: ~138 W/m·K, suitable for heat dissipation applications.

Electrical Conductivity: Approximately 33% IACS.

Melting Point: 590 – 650 °C, ensuring thermal stability in marine conditions.

Manufacturing Process

Marine 5052 Aluminum Plate production generally follows these steps:

Hot Rolling: Aluminum billets are heated and rolled into plates of specified thickness with precise dimensional control.

Cold Working: For tempering and improving mechanical properties as required.

Surface Treatment: Standard mill finish supplied; optional anodizing or painting enhance durability and appearance.

Cutting and Fabrication: Plates can be precision-cut, bent, formed, or welded in line with marine construction standards.

Typical Marine Applications

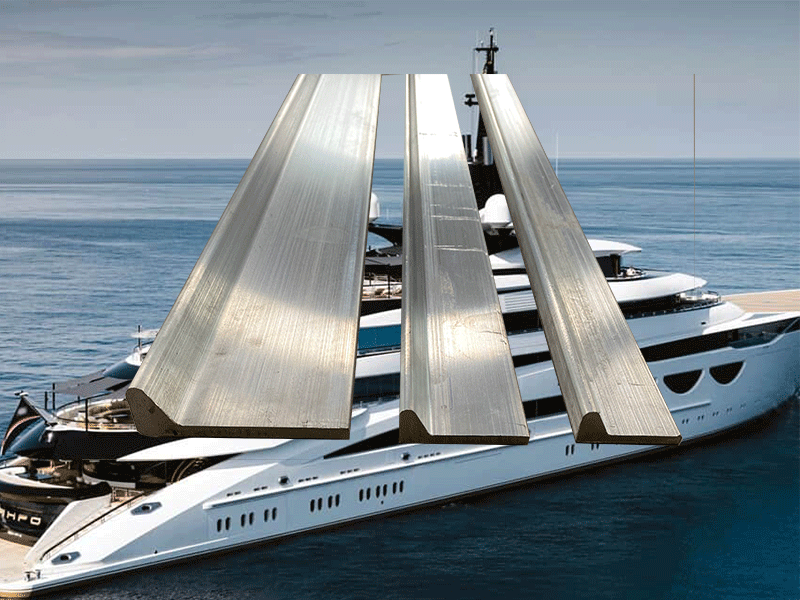

Marine 5052 Aluminum Plate is widely used in:

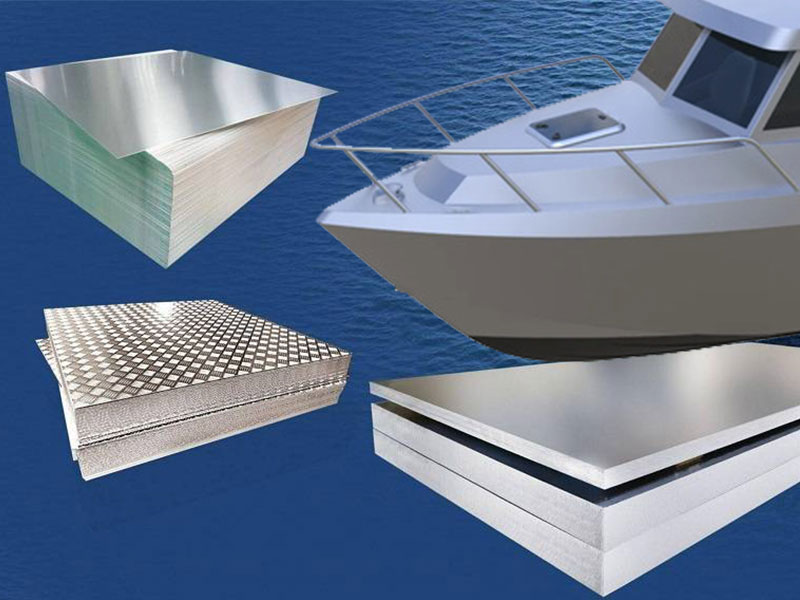

Shipbuilding: Deck plating, bulkheads, and non-structural hull components.

Offshore Platforms: Walkways, stair treads, railings, and equipment enclosures.

Boat Manufacturing: Cabin panels, flooring, fuel tanks, and storage compartments.

Coastal Infrastructure: Bridges, docks, piers, and building façade panels.

Marine Equipment: Pump housings, lightweight containers, and marine-grade transportation boxes.

Food Processing and Chemical Industries: It is non-toxic and corrosion resistant, ideal for marine food processing environments.

Advantages of Marine 5052 Aluminum Plate

Superior Corrosion Resistance: Strong resistance to seawater, salt spray, and marine atmospheres, preventing pitting and crevice corrosion.

Excellent Formability: Can be easily bent, rolled, and shaped to support complex marine hull and equipment designs.

Good Weldability: Compatible with TIG, MIG, and spot welding techniques common in marine fabrication.

Lightweight: Helps reduce overall vessel weight, enhancing fuel efficiency.

Strong Fatigue Resistance: Performs well under cyclic stresses common in marine environments.

Non-Magnetic & Non-Toxic: Makes it suitable for sensitive marine instrumentation and food-grade applications.

Maintenance and Care

To maintain performance and extend service life, 5052 aluminum plates require:

Regular cleaning: Freshwater rinses to remove accumulated salt and marine debris.

Avoidance of harsh chemicals: Use mild detergents and avoid abrasive cleaning tools.

Inspection: Routine checks for scratches, dents, or corrosion, particularly near welds and fastener holes.

Surface Protection: Optional protective coatings, such as marine-grade paint or anodizing for enhanced aesthetics and corrosion defense.

Marine 5052 Aluminum Plate provides an excellent combination of corrosion resistance, mechanical strength, and workability optimized for marine applications. Its lightweight but durable characteristics make it favorable for bulkheads, tanks, flooring, and many other shipbuilding and offshore platform components. With superior resistance to marine environmental challenges, 5052 aluminum plate ensures long-lasting, low-maintenance service life, supporting safe and efficient marine operations.

For customized specifications or technical assistance, please contact our sales and engineering experts who can guide you in selecting the ideal marine aluminum plate for your project.