Why Marine Aluminum Plates Are Essential for Hull Construction and Decking

Marine aluminum plates have revolutionized shipbuilding and vessel design by offering a unique combination of strength, durability, and corrosion resistance tailored specifically for harsh marine environments. Their vital role in hull construction and decking underpins many of the advances in modern marine engineering, enabling the production of safer, lighter, and more efficient vessels.

The Critical Role of Hulls and Decks

The hull of a vessel is its primary structural barrier against the unforgiving marine environment, responsible for buoyancy, stability, and integrity under diverse and dynamic loads. Decking serves as the main working surface, burdened with passenger and cargo loads, environmental exposure, and mechanical stresses.

Materials used for hulls and decks must therefore provide:

Resistance to constant seawater corrosion and salt spray

Structural strength to withstand wave impacts, bending, and torsion

Durability against wear, abrasion, and mechanical damage

Weight efficiency to enhance performance and payload capacity

Compatibility with fabrication and welding processes for complex designs

Marine aluminum plates meet and exceed these demands, making them essential in contemporary shipbuilding.

Properties of Marine Aluminum Plates for Hulls and Decks

1. Superior Corrosion Resistance

Marine aluminum alloys, typically from the 5xxx series (e.g., 5083, 5086), contain magnesium and other elements that provide outstanding resistance to seawater and marine atmospheric corrosion. The formation of a stable aluminum oxide layer acts as a natural protective barrier, preventing pitting and crevice corrosion common in saltwater environments.

2. High Strength-to-Weight Ratio

Aluminum’s low density (~2.66 g/cm³) allows marine plates to deliver the necessary structural strength while significantly reducing weight compared to traditional steel hulls and decks. This weight savings translates into:

Increased fuel efficiency and reduced emissions

Greater payload capacity

Enhanced vessel speed and maneuverability

3. Excellent Weldability and Fabricability

Marine aluminum plates can be readily welded using TIG, MIG, and friction stir welding methods, forming strong, corrosion-resistant joints vital for hull and deck integrity. Their formability enables fabrication of intricate hull shapes and deck configurations demanded by modern ship designs.

4. Fatigue and Impact Resistance

Marine vessels encounter cyclic loads and wave impacts; aluminum alloys like 5083 maintain toughness and resist fatigue failures over prolonged service life, ensuring hull resiliency under harsh operational conditions.

5. Maintenance and Longevity Benefits

Compared to steel, aluminum hull and deck plates require less maintenance due to their corrosion resistance, reducing downtime and lifecycle operating costs for ship operators and owners.

Typical Applications of Marine Aluminum Plates in Hulls and Decks

Hull Plating: Aluminum plates form the outer skin of the ship’s hull, resisting penetration, corrosion, and impacts from the marine environment.

Deck Plating: Deck aluminum plates act as the functional work surfaces and protective layers, exposed to foot traffic, equipment loads, and weather elements.

Bulkheads and Internal Panels: Aluminum plates are used internally for structural bulkheads, helping maintain watertight compartments and ship stability.

Superstructure Components: Lightweight aluminum panels reduce top weight to improve vessel stability and reduce center of gravity.

Why Choose Marine Aluminum Plates Over Traditional Materials?

| Criterion | Marine Aluminum Plates | Steel Plates | Composite Materials |

|---|---|---|---|

| Corrosion Resistance | Excellent natural resistance to seawater | Prone to rust without coatings | Varies; can degrade under UV exposure |

| Density | Lightweight (2.66 g/cm³) | Heavy (7.85 g/cm³) | Lightweight but may lack structural strength |

| Strength | High tensile/yield strength, fatigue resistant | Very strong but heavier | Moderate strength, often lower durability |

| Fabrication | Easily welded, formed, machined | Well-established, heavier fabrication | Specialized processes needed |

| Maintenance | Low maintenance, long life | Requires frequent paint or cathodic protection | Maintenance varies depending on matrix |

| Sustainability | Fully recyclable aluminum | Recyclable steel but consumes more energy | Difficult to recycle, environmental concerns |

Fabrication and Installation Considerations

Optimized Plate Thickness: Marine aluminum plates are available in various thicknesses for strict compliance with structural and safety standards.

Advanced Welding Technology: Proper welding techniques preserve corrosion resistance and mechanical properties.

Surface Treatments: Anodizing or marine coatings augment corrosion protection and improve aesthetics.

Joint Design: Attention to joint design and fasteners avoids galvanic corrosion and mechanical failure.

Marine aluminum plates have established themselves as a cornerstone material in modern hull construction and decking due to their unmatched corrosion resistance, high strength-to-weight ratio, and fabrication versatility. Their use results in vessels that are safer, more efficient, easier to maintain, and more environmentally sustainable. Shipbuilders and marine engineers choosing marine aluminum plates benefit from superior performance and long-term cost savings.

For tailored advice on marine aluminum plate selection, specifications, and fabrication support, consult with our marine metals specialists to ensure your vessel or marine project leverages the full advantages of this essential material.

Related Products

Marine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsRelated Blog

6061 T6 T651 Marine Grade Aluminum Plate Sheet

When it comes to selecting the ideal material for marine applications, nothing quite matches the balanced strength, corrosion resistance, and versatility of the 6061 T6 T651 marine grade aluminum plate sheet.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View DetailsMarine Grade 5083, 5082 Aluminum Alloy Sheet Plate

When it comes to materials that perform exceptionally under the harsh conditions of marine environments, Marine Grade aluminum alloys like 5083 and 5082 hold a revered place in the industry’s toolkit.

View DetailsMarine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View DetailsMarine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

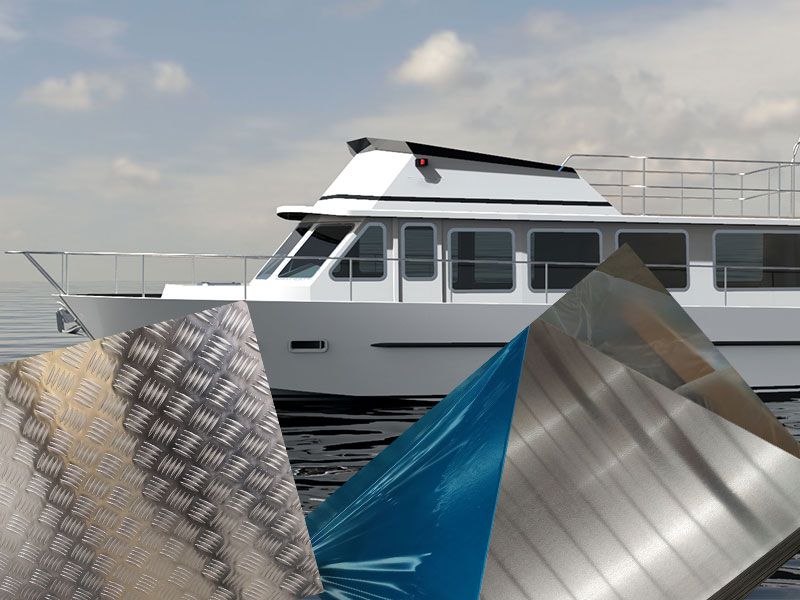

View DetailsMarine 5083 5086 H116 Checkered Aluminum Plate for Deck Board

Premium Marine 5083/5086 H116 Checkered Aluminum Plate designed for deck boards. Boasting exceptional corrosion resistance, high strength, and durability, it meets marine industry standards for optimal performance in harsh sea environments.

View Details

Leave a Message