Marine 5383 Aluminum Plate is a high-quality, marine-grade aluminum alloy plate engineered for demanding maritime and offshore applications. Known for its excellent corrosion resistance, superior strength, and outstanding durability, 5383 aluminum plate is a trusted choice for shipbuilders, offshore engineers, and coastal infrastructure developers who require materials that withstand harsh saltwater environments without compromising structural integrity.

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength. This alloy is specifically designed for shipbuilding and marine structural applications where the exposure to seawater and salty air is extensive. 5383 Aluminum Plate offers a perfect combination of corrosion resistance, strength, and weldability to meet stringent marine construction standards.

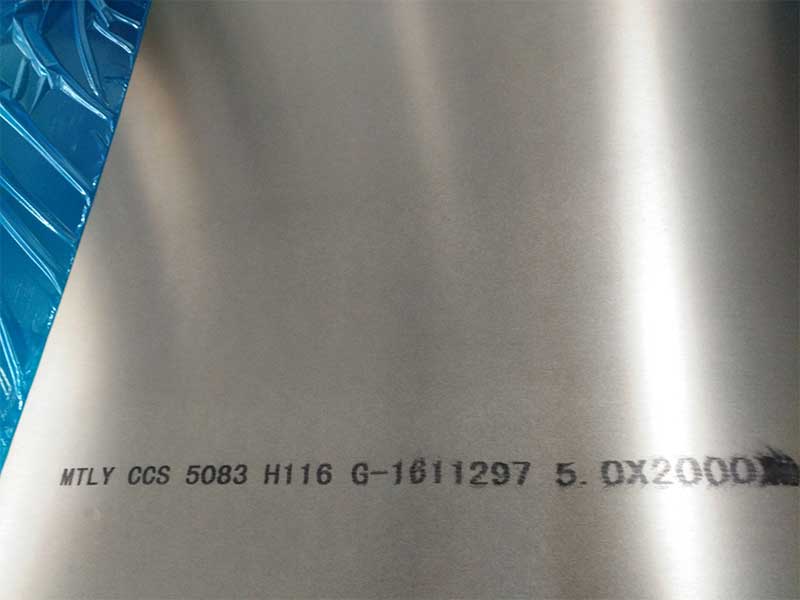

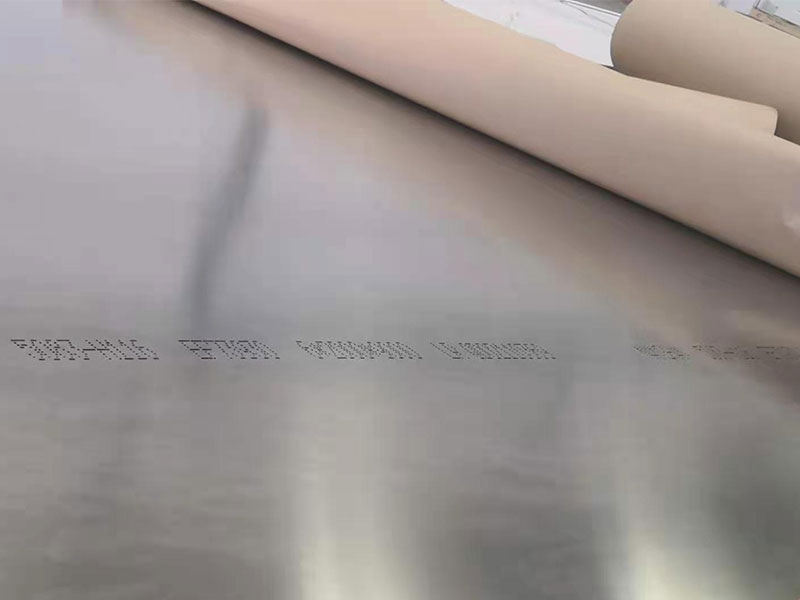

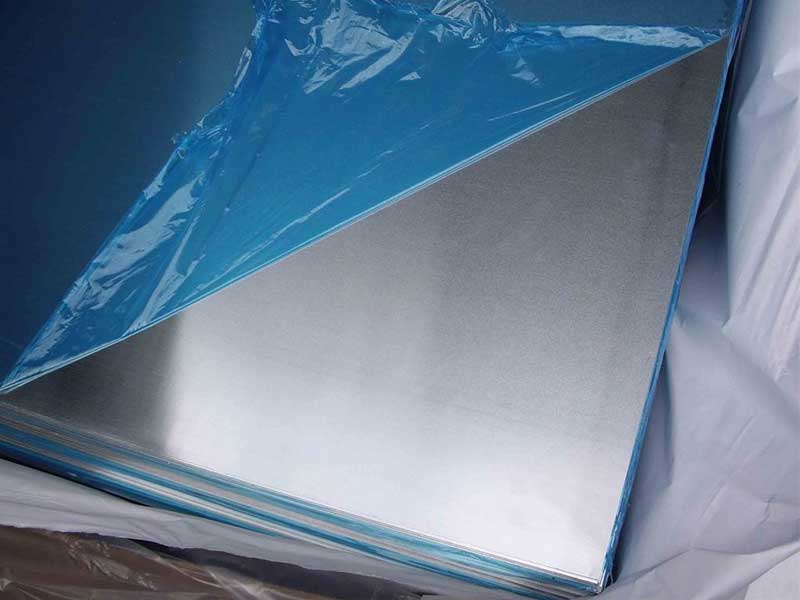

Produced through advanced hot rolling and finishing techniques, Marine 5383 Aluminum Plates maintain high dimensional accuracy and excellent surface quality. The alloy’s capacity to endure marine environmental stress makes it a valuable material for various ship and offshore structures.

Chemical Composition

The typical chemical composition of Marine 5383 Aluminum Plate is optimized to balance strength and corrosion resistance:

| Element | Typical Content (%) |

|---|---|

| Magnesium (Mg) | 4.5 – 5.5 |

| Manganese (Mn) | 0.2 – 0.7 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.3 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.1 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5383 Aluminum Plates are typically offered in tempers such as H32, H112, and H116, optimized for different fabrication requirements.

| Property | 5383-H32 | 5383-H112 | 5383-H116 |

|---|---|---|---|

| Tensile Strength (MPa) | 300 – 360 | 310 – 370 | 320 – 380 |

| Yield Strength (MPa) | 180 – 260 | 190 – 270 | 205 – 290 |

| Elongation (%) | 10 – 15 | 10 – 14 | 10 – 13 |

| Hardness (Brinell) | 75 – 95 | 80 – 100 | 85 – 105 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 |

Physical and Thermal Properties

Density: Approximately 2.66 g/cm³, providing significant weight savings compared to steel.

Thermal Conductivity: ~130 W/m·K, good for heat dissipation in marine machinery enclosures.

Melting Range: 570 - 640 °C, offering stability during fabrication and operational use.

Electrical Conductivity: Moderate, approximately 28–30% IACS.

Manufacturing Process

Marine 5383 Aluminum Plates undergo multiple stages during manufacture:

Hot Rolling: To achieve uniform plate thickness and enhance mechanical strength.

Cold Working: Applied to attain the desired temper and balance ductility and strength.

Surface Treatment: Mill finish is standard; anodizing or painting options can improve surface protection and aesthetics.

Cutting and Fabrication: Precision cutting, welding, forming, and machining can be performed following marine industry standards.

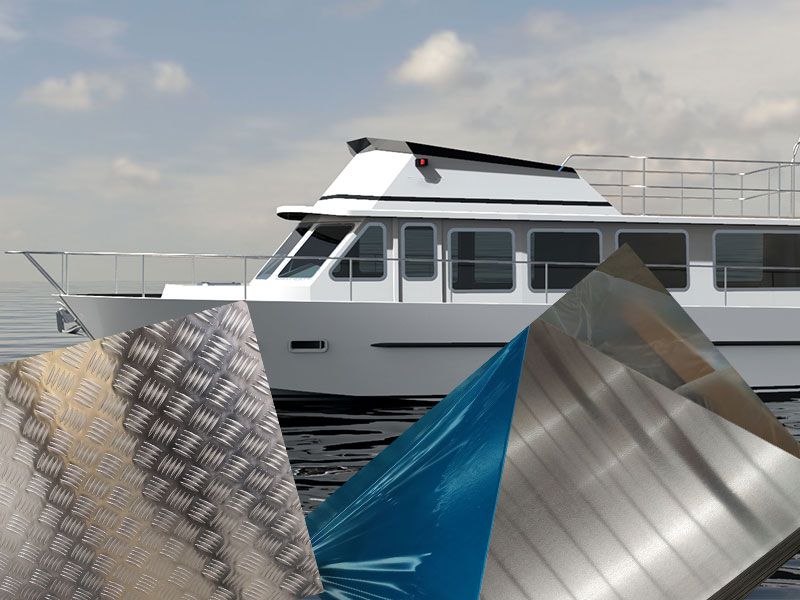

Typical Marine Applications

Given its properties, Marine 5383 Aluminum Plate is widely applied in:

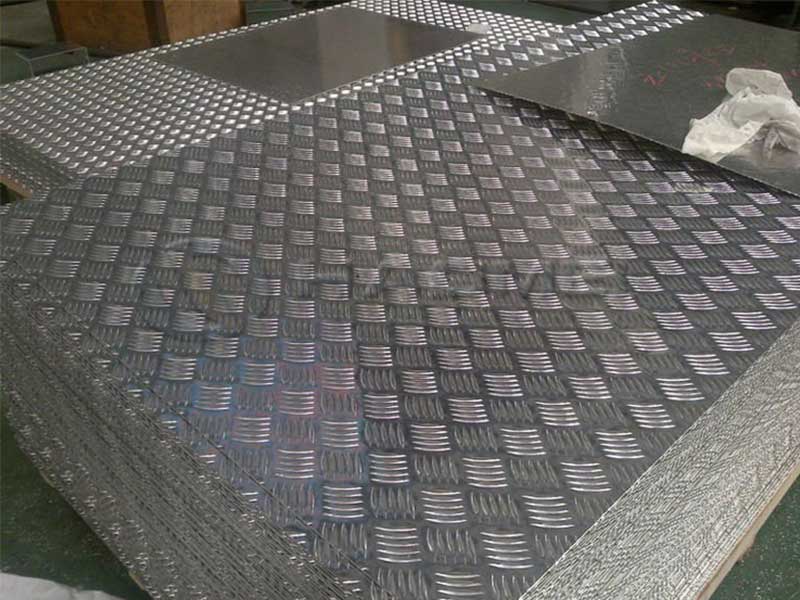

Shipbuilding: Hulls, bulkheads, and decks where a strong, corrosion-resistant plate is essential.

Offshore Structures: Structural components on oil and gas platforms, walkways, and staircases.

Boat Fabrication: Decks, superstructures, and cabin panels for commercial and recreational vessels.

Marine Tanks: Fuel and water tanks requiring corrosion resistance and structural strength.

Coastal Infrastructure: Piers, bridges, and dock components exposed to salt spray and marine weather.

Marine Equipment: Enclosures, frames, and protective housings.

Advantages of Marine 5383 Aluminum Plate

Excellent Corrosion Resistance: Strong performance against seawater and marine atmosphere attacks including pitting and crevice corrosion.

High Mechanical Strength: Suitable for structural applications requiring load-bearing capacity.

Good Weldability: Compatible with TIG, MIG, and resistance welding methods ensuring ease of fabrication and repairs.

Good Formability: Enables cold bending and shaping without cracking.

Lightweight Material: Enhances vessel efficiency by reducing overall weight while maintaining strength.

Sustainable and Recyclable: Aluminum’s recyclability supports environmentally responsible marine engineering.

Maintenance and Care

To maintain Marine 5383 Aluminum Plate performance:

Regular Freshwater Cleaning: Removes salt, marine organisms, and contaminants.

Avoid Abrasive Chemicals: Use mild detergents and soft cleaning tools to protect the surface.

Inspect for Damage: Check for dents, scratches, or corrosion starting points, especially near welds.

Protective Coatings: Consider anodizing or painting for environments with severe corrosive elements.

Welding Repairs: Execute with appropriate filler metal and procedures to maintain corrosion resistance and strength.

Marine 5383 Aluminum Plate provides an excellent balance between corrosion resistance, mechanical strength, and fabricability, making it a first-choice plate alloy in marine and offshore industries. Its proven performance in the toughest saltwater conditions ensures structural reliability and longevity across a broad range of maritime applications.

For project-specific specifications, technical assistance, or pricing inquiries, please contact our dedicated sales and engineering team for expert guidance tailored to your marine aluminum requirements.