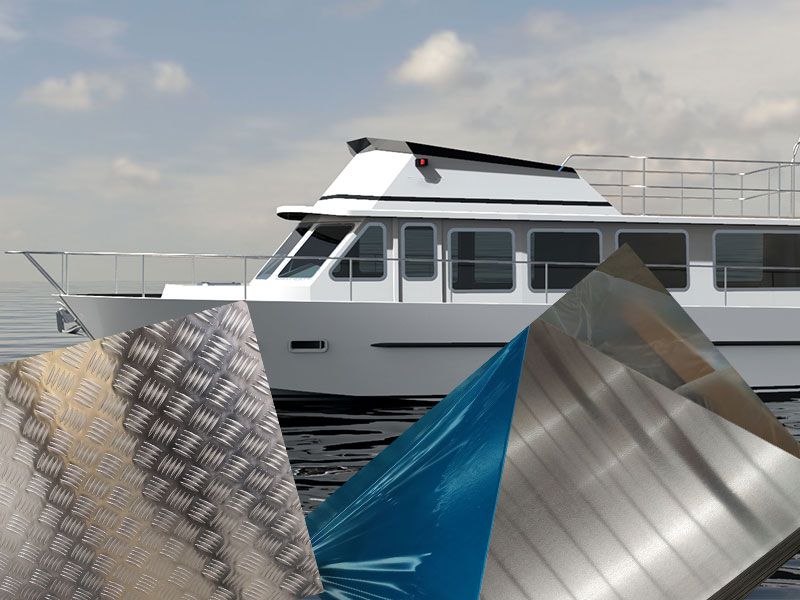

Marine Aluminum / Steel Clad Plates are advanced composite materials that combine the lightweight corrosion resistance of marine-grade aluminum with the superior strength and toughness of steel. Engineered to optimize the performance characteristics of both metals, these clad plates are increasingly used in marine, offshore, and coastal engineering applications where a perfect balance between structural strength, weight savings, and durability is critical.

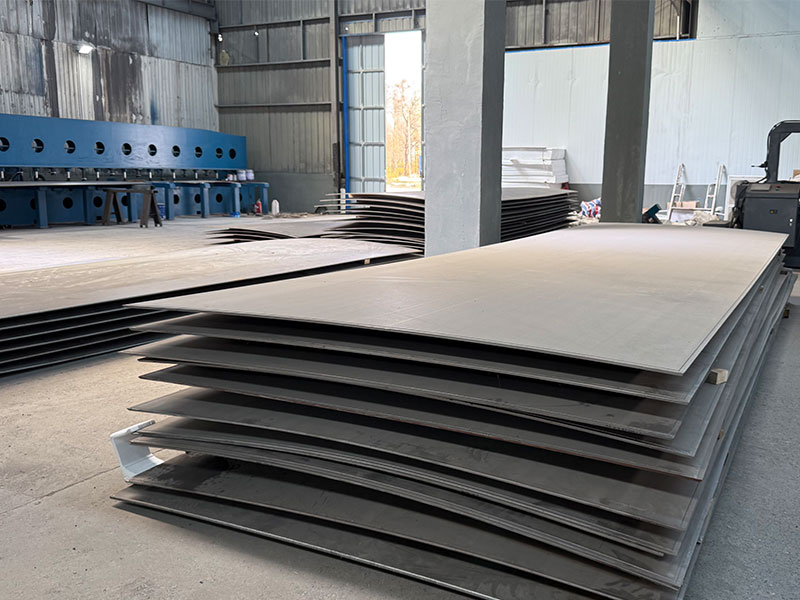

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate. This innovative fusion creates a composite plate that offers the corrosion resistance and lightweight benefits of aluminum on the surface exposed to seawater, while delivering the mechanical strength, impact resistance, and cost advantages of steel on the structural side.

Typical marine alloy used on the aluminum side includes 5xxx series such as 5083 or 5052, known for their exceptional saltwater corrosion resistance. The steel plate is generally mild steel or high-strength structural steel, chosen to meet the mechanical load requirements. The metallurgical bonding process—often explosive welding or roll bonding—guarantees a strong, durable interface free of delamination under service conditions.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Composite Material Design | Combines aluminum's corrosion resistance with steel's high strength and toughness | Optimizes vessel weight and structural performance |

| Marine-Grade Aluminum Cladding | Typically 5083 or 5052 alloy with excellent seawater corrosion resistance | Superior protection against galvanic, pitting, and crevice corrosion |

| High-Quality Metallurgical Bond | Fusion bonding methods ensure no separation or weak interface between aluminum and steel | Long-term durability and reliability under marine stress |

| Weight Reduction | Aluminum surface reduces overall weight compared to all-steel plates | Enhances fuel efficiency and vessel payload capacity |

| Cost Efficiency | Steel backing minimizes use of expensive marine aluminum without sacrificing performance | Cost-effective solution for heavy structural applications |

| Improved Fabricability | Composite plate is weldable, machinable, and formable with standard marine fabrication methods | Facilitates easier installation and repairs |

| Thermal and Electrical Properties | Aluminum layer provides excellent thermal conductivity and electrical insulation properties | Improves marine equipment performance and safety |

Construction and Materials

Aluminum Side

Alloy Grades: 5083-H116, 5052-H32, or similar marine-grade aluminum alloys.

Thickness Range: Typically 1 mm to 10 mm, customized based on exposure and corrosion resistance needs.

Properties: High corrosion resistance, good strength, lightweight.

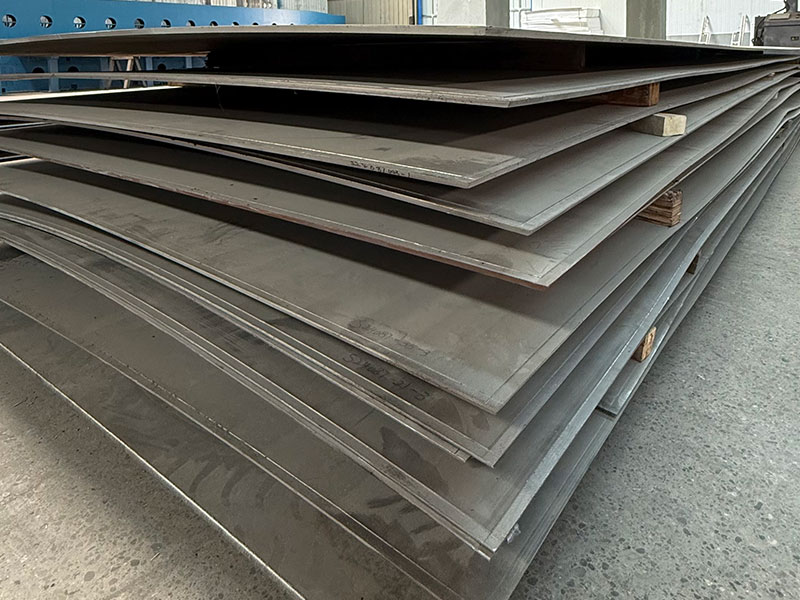

Steel Side

Grades: Mild steel (e.g., ASTM A36), high-strength structural steels, or naval grade steels as per application.

Thickness Range: Typically 8 mm to 100+ mm depending on structural requirements.

Properties: High tensile strength, excellent toughness, affordable cost.

Manufacturing Process

Explosive Welding: High-velocity metal impact causes solid-state bonding between aluminum and steel layers without melting, preserving mechanical properties.

Roll Bonding: Under extreme pressure and temperature, the metals are joined through plastic deformation.

Quality Assurance: Ultrasonic testing, shear testing, and metallographic analysis ensure bond integrity and absence of defects.

Mechanical Properties

The composite plate’s properties depend on thickness ratio and alloy grades, but typical properties include:

| Property | Aluminum Layer (e.g. 5083-H116) | Steel Layer (e.g. A36) | Combined Plate (Weighted Average) |

|---|---|---|---|

| Tensile Strength (MPa) | 300 - 350 | 250 - 400 | 350 - 450 (varies by thickness) |

| Yield Strength (MPa) | 215 - 275 | 200 - 350 | 250 - 380 |

| Elongation (%) | 12 - 16 | 20 - 30 | 15 - 25 |

| Density (g/cm³) | 2.66 | 7.85 | 4.0 - 6.5 (depending on layers) |

| Corrosion Resistance | Excellent in marine environments | Susceptible to corrosion | Excellent on aluminum-exposed side |

Typical Marine Applications

Ship Hull and Deck Components: Aluminum surface protects from seawater; steel core provides structural strength.

Offshore Platforms: Structural support panels and walkways combining corrosion resistance with load-bearing strength.

Marine Tanks and Containers: Lightweight corrosion-resistant exteriors with robust structural backing.

Dock and Pier Structures: Durable and cost-effective composite plates for harsh saltwater exposure.

Marine Protective Panels: Anti-corrosion cladding on steel frameworks and equipment housings.

Advantages Over Conventional Materials

| Criteria | Marine Aluminum / Steel Clad Plate | Monolithic Steel Plate | Monolithic Aluminum Plate |

|---|---|---|---|

| Corrosion Resistance | Aluminum protects the exposed surface | Steel requires coatings or corrosion allowance | High corrosion resistance but costly and lower strength |

| Weight | Significantly lighter than all-steel | Heavy | Lightweight |

| Structural Strength | Steel backing provides excellent strength | Strong | Moderate strength |

| Cost | Moderate cost due to material optimization | Lower material cost but high maintenance | High material cost |

| Fabrication | Weldable and workable with standard methods | Easy fabrication | Good workability but requires expertise |

| Maintenance | Low maintenance on aluminum surface | Requires regular anti-corrosion measures | Low maintenance |

Maintenance and Handling

Regular inspection of aluminum surface for mechanical damage or wear.

Freshwater rinsing to remove salt deposits and contaminants.

Avoid galvanic corrosion by ensuring proper insulation where aluminum contacts dissimilar metals other than steel backing.

Follow welding and repair guidelines specific to clad plates to maintain bond integrity.

Marine Aluminum / Steel Clad Plates are a sophisticated composite solution tailored for marine and offshore industries demanding corrosion resistance, structural toughness, and weight efficiency. By leveraging the best properties of both aluminum and steel, these plates offer significant advantages in durability, cost-effectiveness, and performance over traditional homogenous materials. Whether for ship hulls, offshore platforms, or coastal infrastructure, aluminum/steel clad plates are a superior choice for challenging marine conditions.

Contact and Ordering Information

We provide Marine Aluminum / Steel Clad Plates customized in thickness, alloy grades, and dimensions to meet project-specific demands. For technical consultation, detailed specifications, pricing, and fabrication support, please contact our expert sales engineering team.