Marine 5086 Aluminum Plate is a premium-quality aluminum-magnesium alloy plate widely regarded as one of the most versatile and reliable marine-grade materials available today. Known for its outstanding strength, excellent corrosion resistance, and superior weldability, 5086 aluminum plate is specifically engineered to perform in the harsh, saltwater marine environment. It is extensively used across shipbuilding, offshore platforms, yacht construction, and various coastal infrastructures.

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions. Additionally, the alloy demonstrates superior strength properties relative to many other aluminum alloys in the same series, making it an ideal structural material for marine and offshore applications that demand durability, toughness, and longevity.

Manufactured using advanced hot rolling and cold working techniques, Marine 5086 Aluminum Plate ensures precise thickness, excellent flatness, consistent mechanical properties, and a quality surface finish suitable for direct marine use or further fabrication.

Chemical Composition

The typical chemical composition of Marine 5086 Aluminum Plate is formulated for optimal corrosion resistance and mechanical performance:

| Element | Typical Content (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.2 – 0.7 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5086 Aluminum Plates are commonly supplied in tempers such as H32, H34, and H116. Each temper balances strength and ductility to suit different fabrication needs. The table below outlines typical mechanical properties:

| Property | 5086-H32 | 5086-H34 | 5086-H116 |

|---|---|---|---|

| Tensile Strength (MPa) | 275 – 350 | 295 – 350 | 300 – 360 |

| Yield Strength (MPa) | 145 – 230 | 165 – 240 | 190 – 260 |

| Elongation (%) | 12 – 18 | 10 – 15 | 10 – 14 |

| Brinell Hardness (HB) | 75 – 95 | 80 – 100 | 90 – 105 |

| Density (g/cm³) | 2.66 | 2.66 | 2.66 |

Physical and Thermal Properties

Density: Approximately 2.66 g/cm³, substantially lighter than steel, ideal for applications requiring weight savings.

Thermal Conductivity: Around 130 W/m·K, beneficial for heat dissipation in marine machinery and equipment.

Melting Range: 570–640 °C, allowing thermal stability under typical marine conditions.

Electrical Conductivity: Approximately 28–34% IACS, suitable for applications where moderate electrical conductivity is desired.

Manufacturing Process

Manufacture of Marine 5086 Aluminum Plate involves:

Hot Rolling: To achieve plates of desired thickness with consistent mechanical properties.

Cold Working: Applied to adjust temper and improve mechanical performance.

Surface Finishing: Plates are generally provided with a mill finish but can be anodized, painted, or coated based on project needs.

Cutting and Fabrication: Plates are custom cut, machined, welded, and formed using conventional marine manufacturing methods.

Typical Marine Applications

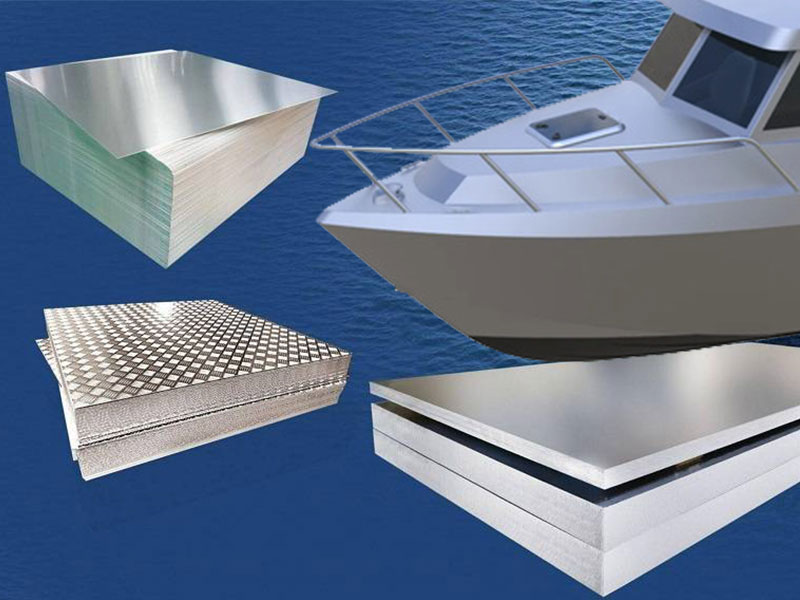

Marine 5086 Aluminum Plate is used in a wide spectrum of marine and offshore contexts, including:

Vessel Hulls and Superstructures: Offering strength and corrosion protection where seawater contact is constant.

Offshore Oil and Gas Platforms: Structural panels, walkways, stairs, and containment units.

Boat and Yacht Fabrication: Decks, bulkheads, cabins, and structural frameworks.

Marine Tanks and Containers: For fuel, freshwater, and chemical storage with excellent corrosion resistance.

Coastal Infrastructure: Bridges, piers, docks, and shore protection structures exposed to salt spray.

Specialized Marine Equipment: Crates, transport containers, and marine HVAC housings.

Advantages of Marine 5086 Aluminum Plate

Exceptional Corrosion Resistance: Performs extremely well in seawater and marine atmospheres due to magnesium and chromium alloying.

High Strength: Offers tensile and yield strength superior to many aluminum alloys while remaining lightweight.

Weldable: Easily welded with common methods such as MIG, TIG, and resistance welding without compromising corrosion resistance.

Good Workability: Excellent cold-forming ability allowing bending, rolling, and shaping.

Non-Magnetic and Non-Toxic: Ideal for specialized applications where magnetic interference or contamination needs to be minimized.

Sustainable Material: Aluminum is fully recyclable, offering environmental benefits.

Maintenance and Care

To ensure the longevity and sustained performance of Marine 5086 Aluminum Plates:

Routine Cleaning: Regular rinsing with fresh water to remove salt deposits and marine growth.

Avoid Abrasive Cleaning: Use mild detergents and non-abrasive tools to maintain surface integrity.

Surface Inspection: Periodically inspect for mechanical damage, scratches, or corrosion, especially near welds and fasteners.

Protective Coatings: Anodizing or marine-grade painting can provide additional corrosion protection if necessary.

Proper Welding Practices: Use qualified welding procedures and compatible filler metals to maintain alloy characteristics.

Marine 5086 Aluminum Plate represents a balanced solution for marine and offshore applications where high corrosion resistance, structural strength, and fabrication flexibility are paramount. Its proven track record in shipbuilding, offshore platform construction, and coastal infrastructure underscores its value as a reliable, efficient, and long-lasting marine-grade alloy.

For project-specific consultation, technical support, or quotations, please reach out to our expert sales and engineering team who can assist you in choosing the optimal Marine 5086 Aluminum Plate for your needs.