5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications, 5052 marine aluminum tubes offer unparalleled performance, combining mechanical properties with excellent resistance to saline waters and harsh climates.

5052 aluminum is part of the 5xxx series alloys, renowned for its high magnesium content (approximately 2.5%) that enables exceptional corrosion resistance, especially in marine atmospheres. It is a non-heat-treatable alloy, relying on cold working processes to enhance its strength.

Chemical Composition of 5052 Aluminum Alloy

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | 0.10 |

| Iron (Fe) | 0.40 (max) |

| Copper (Cu) | 0.10 (max) |

| Silicon (Si) | 0.25 (max) |

| Zinc (Zn) | 0.10 (max) |

| Titanium (Ti) | 0.03 (max) |

Features of 5052 Marine Aluminum Tubes

Superior Corrosion Resistance

- 5052 aluminum exhibits excellent resistance to seawater, salt spray, freshwater, seawater, and corrosive environments, making it ideal for sustained use at sea.

High Strength and Excellent Weldability

- After cold working, the alloy reaches medium to high strength while retaining excellent weldability, connectivity that marine fabrications demand.

Good Workability and Formability

- Easy to extrude and form into tubes with precision, enabling complex shapes while maintaining structural integrity.

Lightweight with High Strength-to-Weight Ratio

- Significantly lighter than steel while still providing comparable strength, contributing to fuel efficiency and ease of handling.

Enhanced Surface Finish Properties

- The alloy typically features good anodizing quality and surface finish, protecting tubes against marine wear.

Mechanical Properties of 5052 Aluminum Tubes

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 220 – 260 MPa |

| Yield Strength | 140 – 190 MPa |

| Elongation (%) | 10 – 20 (depending on temper) |

| Density | 2.68 g/cm³ |

| Modulus of Elasticity | 69 GPa |

| Hardness (Brinell) | 60 – 85 HB |

Temper variations (O, H32, H34, H36) alter mechanical parameters as needed for specific marine uses.

Typical Dimensions and Standards

To meet rigorous shipping and offshore marine requirements, 5052 aluminum tubes adhere to international material standards such as ASTM B series specifications (e.g., ASTM B210 for Aluminum and Aluminum-Alloy Drawn Seamless Tubes).

| Dimension Parameter | Typical Range |

|---|---|

| Outer Diameter (OD) | 6 mm – 100 mm |

| Wall Thickness | 1 mm – 6 mm |

| Length | 1 m – 6 m (customizable) |

| Shape | Round, oval, and rectangular cross sections |

Applications in Heavy Duty Marine Environments

Shipbuilding and Vessel Construction

Frameworks, support structures, railings/handrails, and piping systems deployed in ships, patrol boats, and ferries benefit from 5052 aluminum tubes' corrosion resilience to seawater and mechanical stresses.

Offshore Platforms & Rigs

Structures that require enduring exposure to aggressive environments use 5052 tubes in their scaffolding, pipelines, and connectors for long-term reliability.

Marine Docking and Pier Installations

Used in dock piles, bollards, and structural members of piers that confront tide cycles, salt mist, and abrasion.

Sub-sea Components & Buoyancy Structures

Fabrications in sonar positions, underwater vehicles support, and minor rigs leverage the alloy for watertight constructions.

Cooling and Water Systems

Tubes for saltwater cooling circuits and heat exchangers benefit from the material’s corrosion resistance and heat acceptance properties.

Why Choose 5052 Marine Aluminum Tubes?

- Long lifespan without frequent maintenance in seawater.

- Environmental corrosion resistance reducing the risks of structural failure.

- Competitive weight saving resulting in less fuel consumption and more payload.

- Ease of fabrication expedites marine project timelines and lowers costs.

- Eco-friendly recycling process compatible with industrial sustainability goals.

5052 Marine Aluminum Tubes combine the critical attributes necessary to guarantee heavy-duty marine application success — high corrosion resistance, excellent mechanical strength, lightweight properties, and outstanding formability. These tubes ensure durability and consistent performance across salty, moist, and mechanically stressful environments, making them an industry-preferred solution in demanding marine sectors.

For your next marine project, selecting 5052 aluminum alloy tubing means safer seafaring structures, increased service life, and cost-effective frameworks engineered to overcome the toughest oceanic challenges.

If you'd like more specifications or custom tube dimensions, contact our engineering team for personalized consultation tailored to your marine infrastructure needs.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

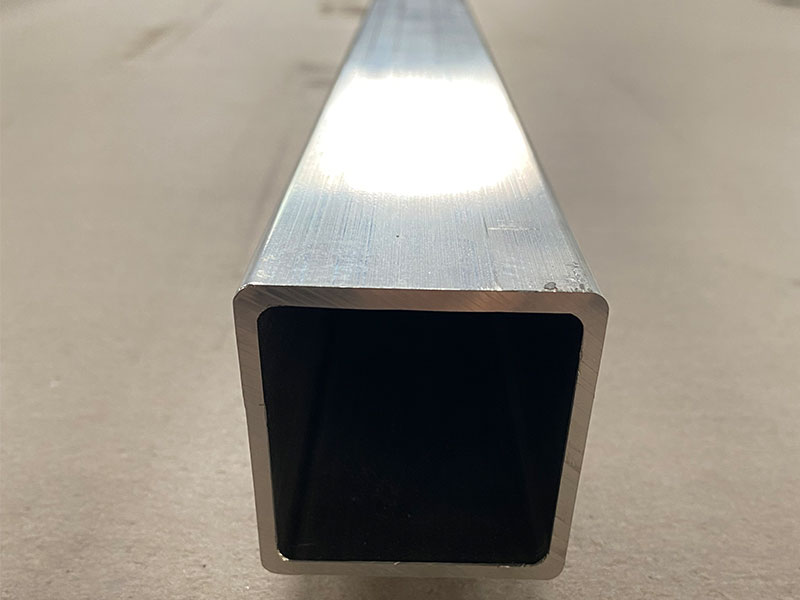

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details

Leave a Message