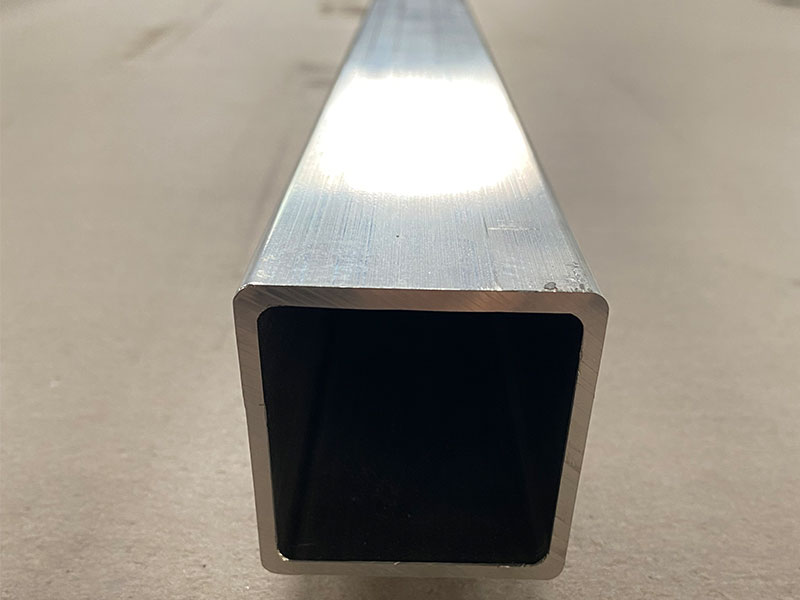

5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength, corrosion resistance, and fabrication versatility.

Why 5052 Aluminum Tubes Are Ideal for Marine Applications

While stainless steel and conventional aluminum alloys find niches, 5052 aluminum excels in environments characterized by saltwater exposure and mechanical stress—common thresholds in shipbuilding scenarios. Unlike many aluminum alloys, which fall short in prolonged exposure to chloride-ion rich seawater, alloy 5052 maintains structural integrity without succumbing to pitting or stress corrosion cracking.

Working with 5052 marine aluminum tubes in shipbuilding presents a unique set of challenges and opportunities. Their excellent corrosion resistance in saltwater environments is a major advantage, making them ideal for applications like railings, handrails, and structural components exposed to harsh conditions. However, the material's relatively lower strength compared to other aluminum alloys necessitates careful consideration of tube wall thickness and design parameters to ensure sufficient structural integrity. We often see issues arising from improper welding techniques, leading to porosity or cracking, so meticulous quality control throughout the fabrication process, from raw material inspection to final weld testing, is paramount. Experience has shown that pre-weld surface preparation, including cleaning and proper joint design, dramatically improves weld quality and longevity.

Beyond the mechanical aspects, efficient material handling and storage are crucial. 5052 aluminum, while corrosion-resistant, can still be susceptible to surface degradation if exposed to prolonged contact with certain contaminants. We've learned to prioritize appropriate storage conditions, utilizing protective coatings when necessary, and minimizing handling to avoid scratches and surface damage that could compromise the tube's lifespan and performance in the marine environment. Furthermore, the specific requirements of different shipbuilding standards and classifications is vital to ensure compliance and guarantee the structural integrity of the final product. This includes familiarity with welding procedures, non-destructive testing (NDT) techniques, and material traceability documentation.

This elevation in performance arises from careful control of magnesium content within 5052 aluminum (2.2%-2.8%), which promotes greater anodic resistance, ultimately forming a robust passive oxide film. The result is offshore-grade tubing that offers a longer service life with minimal maintenance.

Parameters of 5052 Marine Aluminum Tubes

the technical parameters of these tubes ensures precision in selection for engineering parts exposed to dynamic marine conditions:

| Parameter | Specification |

|---|---|

| Alloy Number | 5052 |

| Form | Extruded tubes |

| Outer Diameter Range | 6 mm – 300 mm (customizable) |

| Wall Thickness Range | 0.5 mm – 20 mm |

| Density | 2.68 g/cm³ |

| Melting Point | 605 – 650 °C |

| Yield Strength (Typical) | 193 MPa (H32 temper) |

| Tensile Strength (Typical) | 228 MPa (H32 temper) |

| Elongation at break | 12-20 % (depending on temper) |

| Thermal Conductivity | 138 W/m·K |

Implementation and Quality Standards

Shipbuilding engineers require materials meeting stringent marine construction codes. Our 5052 marine aluminum tubes adhere rigorously to recognized standards including:

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- EN AW-AlMg2.5 (AlMg2.5 F22): Comparable European Alloy designation featuring the marine grade 5052 composition.

- ISO 6362-4: Specifications for drawn seamless tubes.

These ensure dimensional accuracy, mechanical reliability, and surface finish quality imperative to ship construction and maintenance.

Alloy Tempering and Mechanical Properties in 5052 Tubes

The tempering of alloy tubes directly affects mechanical strength and manufacturability. For marine use, H32 temper—which involves strain hardening and partial annealing—is widely employed. The predominant tempers include:

- O (Annealed): Maximum ductility and corrosion resistance but lowest strength.

- H32 (Strain Hardened and Partially Annealed): Offers an optimum balance of workability and mechanical strength, favorably used for hulls and cabinetry.

- H34 (Strain Hardened with Moderate Strength Increase): For more demanding load-bearing marine applications like piping and guardrails.

The choice of temper affects elongation (ability to withstand elongation before fracture) and yield/tensile strength, ensuring engineered parts meet safety requirements under wave impact and vessel vibration.

At the molecular level, the corrosion guard of 5052 aluminum marinutes relies heavily on its element ratios. Below is its standard chemical composition:

| Element | wt.% Range |

|---|---|

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | ≤ 0.10 |

| Copper (Cu) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.40 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.10 |

| Aluminum (Al) | Balance |

Chromium adds further corrosion resistance, inhibiting grain boundary oxidation. The low copper and iron values minimize susceptibility to galvanic corrosion when in contact with dissimilar metals.

Unique Considerations for Using 5052 Tubes in Shipbuilding Engineering

Applying these tubes for engineering parts such as framework, piping, masts, and handrails brings several nuanced advantages:

- Weight Reduction: Lower density than steel leads to lighter vessels improving fuel efficiency.

- Fabrication Flexibility: Good weldability and formability tolerate customized bends and fittings essential in complex ship assemblies.

- Maintenance Cost Savings: High corrosion resistance reduces frequency of protective painting or replacement, lowering lifecycle costs.

- Compatibility: Can be paired with other marine materials, such as stainless steel bolts or composite decks, without rapid galvanic decay.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details

Leave a Message