Marine 5083 Aluminum Plate is a premium-grade aluminum alloy plate specially designed for marine and offshore applications requiring exceptional corrosion resistance, high strength, and superior durability. As one of the most widely used marine-grade aluminum alloys, 5083 aluminum plate combines excellent mechanical properties with unparalleled resistance to seawater and salt spray corrosion, making it the preferred choice for shipbuilders, offshore engineers, and marine fabricators around the world.

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking. It offers excellent weldability, good fatigue resistance, and impressive strength-to-weight ratio, all attributes highly valued in the maritime industry.

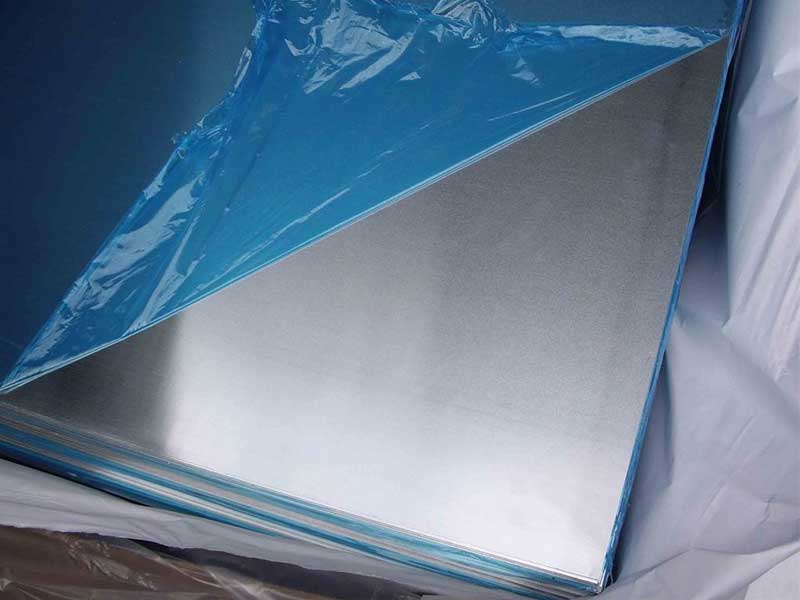

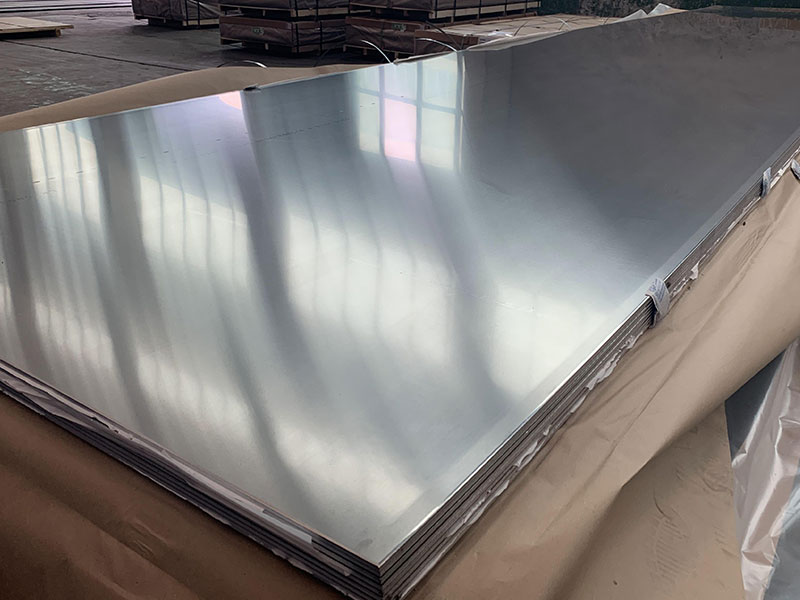

Manufactured using advanced hot rolling and finishing techniques, 5083 aluminum plates are supplied with tight dimensional tolerances, excellent flatness, and superior surface finish suitable for direct fabrication or further processing.

Chemical Composition

The chemical composition of Marine 5083 Aluminum Plate is optimized for marine durability and mechanical performance:

| Element | Content Range (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties

Marine 5083 Aluminum Plates exhibit excellent tensile and yield strength along with good ductility and hardness, which supports their structural performance and fatigue resistance in marine environments. Below are typical mechanical properties for common tempers used in marine applications:

| Property | 5083-H111 | 5083-H321 |

|---|---|---|

| Tensile Strength (MPa) | 275 – 345 | 290 – 350 |

| Yield Strength (MPa) | 125 – 215 | 145 – 215 |

| Elongation (%) | 12 – 24 | 10 – 18 |

| Brinell Hardness (HB) | 70 – 90 | 75 – 95 |

| Density (g/cm³) | 2.66 | 2.66 |

Physical Properties

Density: Approximately 2.66 g/cm³, about one-third the weight of steel, resulting in significantly lighter marine structures.

Thermal Conductivity: ~121 W/m·K aids in heat dissipation for marine engine rooms and components.

Electrical Conductivity: Approximately 28% IACS, providing moderate conductivity useful in marine electrical grounding.

Melting Temperature: 570 – 640 °C, ensuring stability under typical marine thermal conditions.

Manufacturing Process

Marine 5083 Aluminum Plates are typically produced via:

Hot Rolling: Melting and casting followed by hot rolling to required thickness and dimensional tolerances.

Cold Working: Depending on temper requirements, cold working improves strength and formability.

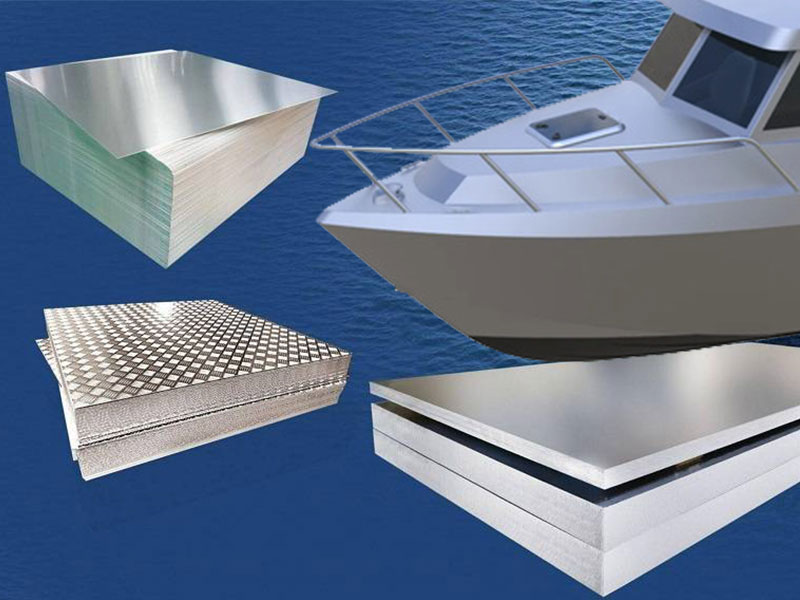

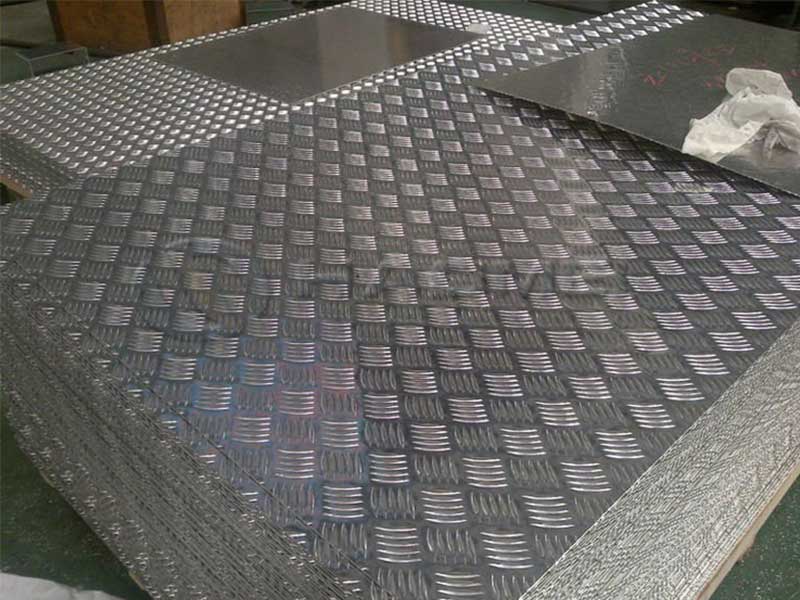

Surface Finishing: Mill finish is standard; anodizing or painting options are available to enhance corrosion resistance and aesthetics.

Cutting & Fabrication: Plates can be custom cut, bent, welded, or machined with precision.

Typical Marine Applications

Marine 5083 Aluminum Plate’s properties make it suitable for an array of marine and offshore applications, including but not limited to:

Shipbuilding: Hull plating, decks, bulkheads, superstructures, and internal framing.

Offshore Platforms: Structural components, walkways, and equipment housing panels.

Marine Tanks: Fuel, water, and chemical storage tanks aboard vessels and offshore rigs.

Boat Manufacturing: Decks, cabins, and hull panels for recreational and commercial vessels.

Coastal and Port Infrastructure: Bridges, piers, walkways, and island structures subjected to saltwater exposure.

Specialty Marine Equipment: Container fabrication, crates, and marine-grade storage equipment.

Advantages of Marine 5083 Aluminum Plate

Exceptional Corrosion Resistance: The high magnesium content and presence of chromium provide robust protection against seawater corrosion and oxidation, substantially outperforming steels in marine exposure.

Lightweight with High Strength: Balances marine structural needs with weight savings, reducing fuel consumption and increasing payload capacity.

Superior Weldability: Excellent compatibility with TIG, MIG, and resistance welding techniques facilitates on-site assembly and repairs.

Good Formability: Allows cold bending and shaping without risk of cracking, enabling complex, customized marine designs.

Environmental Sustainability: Aluminum is 100% recyclable with minimal environmental impact during manufacturing and reuse.

Maintenance and Care

To maximize longevity and preserve performance, the following maintenance guidelines are recommended for Marine 5083 Aluminum Plate:

Regular Cleaning: Frequent rinsing with freshwater to remove salt deposits and marine growth.

Avoid Abrasive Cleaning: Use mild detergents and soft brushes to prevent surface scratching.

Inspection: Periodically check for dents, scratches, or corrosion, especially in weld zones.

Protective Coatings: In highly corrosive environments, consider anodizing or marine-grade paint for additional protection.

Repairs: Welding repairs should be done with correct filler alloys and pre/post-heat treatment per marine standards.

Marine 5083 Aluminum Plate is an outstanding material for marine and offshore applications demanding a balance of corrosion resistance, strength, and weight efficiency. Its proven track record in shipbuilding and offshore industries underscores its reliability, environmental adaptability, and versatility. Whether used for hull plating, structural components, or specialized marine equipment, 5083 aluminum plate provides an optimal solution ensuring safety, durability, and operational efficiency.

For tailored specifications, technical support, or quotations, please reach out to our expert sales and engineering team to assist you in selecting the ideal marine aluminum plate for your next project.