Marine Aluminum Rod & Bar for Lightweight Marine Frame Reinforcement

Marine structures demand materials that combine low weight, high strength, and long-term corrosion resistance in harsh saltwater environments. Marine aluminum rod and bar products are engineered specifically to meet these needs, providing an efficient solution for reinforcing hulls, decks, superstructures, and onboard frameworks without adding excessive weight.

Marine aluminum rod & bar are solid extruded profiles produced from marine-grade aluminum alloys (commonly 5xxx and 6xxx series) optimized for:

- Lightweight structural reinforcement

- Excellent corrosion resistance in seawater

- Good weldability and fabrication

- Stable mechanical properties over a wide temperature range

These products are typically supplied as:

- Round rod: Ø6–300 mm

- Square & rectangular bar: 10×10 mm up to heavy rectangular sections

- Custom profiles for OEM marine structures

Common alloys for marine frame reinforcement:

- 5083 – High strength, excellent seawater corrosion resistance

- 5086 – Good strength, superb corrosion resistance, good toughness

- 6061 / 6082 – Heat-treatable, high strength, excellent machinability, good corrosion resistance (used above waterline and for secondary structures)

2. Features & Advantages

2.1 Lightweight Strength

Marine aluminum offers a high strength-to-weight ratio, enabling robust reinforcement with less mass compared to steel.

| Property | Typical Marine Aluminum (5083) | Mild Steel (A36) |

|---|---|---|

| Density (g/cm³) | ~2.66 | ~7.85 |

| Yield Strength (MPa) | 215–240 | ~250 |

| Strength / Density (MPa·cm³/g) | ~81–90 | ~32 |

Benefit: Similar strength to mild steel at roughly one-third the weight, easing installation and improving vessel efficiency.

2.2 Marine-Grade Corrosion Resistance

5xxx and 6xxx marine alloys form a stable oxide film and exhibit:

- High resistance to chloride-induced pitting

- Minimal galvanic corrosion when paired correctly and isolated from dissimilar metals

- Long service life in immersed, splash, and atmospheric marine zones

Result: Less frequent replacement, reduced maintenance cost, and improved long-term reliability of frames and stiffeners.

2.3 Excellent Fabricability & Weldability

Marine aluminum rod and bar can be:

- Cut, drilled, and machined with standard equipment

- Formed and bent (especially 5xxx alloys) without cracking when proper radii and procedures are used

- Welded using MIG or TIG with commonly available marine filler wires (e.g., ER5356, ER5183, ER5556)

This makes them ideal for shipyard fabrication, field modifications, and repair work.

2.4 Fatigue & Impact Performance

Hull and frame members are often exposed to dynamic wave loading, vibration, and occasional impact. Marine aluminum alloys offer:

- Good fatigue resistance for cyclic loading

- Stable toughness at low temperatures (e.g., North Atlantic operations)

- Adequate impact resistance when used with proper design thickness and weld details

3. Typical Chemical Composition

Below is indicative composition data for commonly used marine alloys in rod & bar products. Actual values may vary slightly by standard and supplier.

3.1 Alloy 5083 (Marine Structural)

| Element | Typical Range (%) |

|---|---|

| Mg | 4.0 – 4.9 |

| Mn | 0.4 – 1.0 |

| Cr | 0.05 – 0.25 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Al | Balance |

3.2 Alloy 5086 (High Corrosion Resistance)

| Element | Typical Range (%) |

|---|---|

| Mg | 3.5 – 4.5 |

| Mn | 0.2 – 0.7 |

| Cr | 0.05 – 0.25 |

| Fe | ≤ 0.50 |

| Si | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Al | Balance |

3.3 Alloy 6082 (High-Strength 6xxx)

| Element | Typical Range (%) |

|---|---|

| Mg | 0.6 – 1.2 |

| Si | 0.7 – 1.3 |

| Mn | 0.4 – 1.0 |

| Fe | ≤ 0.50 |

| Cu | ≤ 0.10 |

| Cr | ≤ 0.25 |

| Zn | ≤ 0.20 |

| Ti | ≤ 0.10 |

| Al | Balance |

4. Mechanical Properties & Performance

Representative mechanical properties for typical tempers used in marine frame reinforcement:

4.1 Typical Mechanical Properties

| Alloy | Temper | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) | Brinell Hardness HBW |

|---|---|---|---|---|---|

| 5083 | O / H111 | 125 – 160 | 270 – 330 | 12 – 18 | 75 – 95 |

| 5083 | H116 / H321 | 215 – 240 | 300 – 340 | 10 – 14 | 90 – 100 |

| 5086 | H116 | 190 – 230 | 275 – 315 | 10 – 16 | 80 – 95 |

| 6082 | T6 | 260 – 310 | 300 – 340 | 8 – 12 | 90 – 100 |

Values are typical and for reference; design should follow relevant marine and classification standards.

4.2 Physical Properties

| Property | 5xxx Series (Typical) | 6082-T6 (Typical) |

|---|---|---|

| Density (kg/m³) | 2,650 – 2,680 | ~2,700 |

| Modulus of Elasticity (GPa) | ~70 | ~70 |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 23–25 | 23–24 |

| Thermal Conductivity (W/m·K) | 120 – 150 | 150 – 170 |

5. Standard Dimensions & Tolerances

5.1 Typical Size Range

| Product Type | Common Sizes (mm) | Length (mm) |

|---|---|---|

| Round Rod | Ø6 – Ø300 | 3,000 – 6,000 |

| Square Bar | 10×10 – 150×150 | 3,000 – 6,000 |

| Rectangular Bar | 10×20 – 80×300 | 3,000 – 6,000 |

| Custom Profile | On request (CAD-based) | As per project design |

5.2 Dimensional Tolerances (Indicative)

| Diameter / Width (mm) | Dimensional Tolerance (mm) |

|---|---|

| ≤ 20 | ±0.15 |

| > 20 – 60 | ±0.25 |

| > 60 – 150 | ±0.50 |

| > 150 | By agreement |

Exact tolerances follow EN, ASTM, or customer drawings.

6. Applications in Marine Frame Reinforcement

Marine aluminum rod and bar are widely used across different vessel types, from small workboats to large passenger ferries and offshore support vessels.

6.1 Structural Frames & Stiffeners

- Longitudinal and transverse frame members

- Deck girders and cross beams

- Bulkhead stiffeners and coamings

- Reinforcement around openings: doors, hatches, windows

Benefit: Weight reduction in large repetitive structures significantly improves fuel economy and increases payload or range.

6.2 Superstructures & Deckhouses

- Cabin framing and internal skeletons

- Bridge and wheelhouse supports

- Mast bases and support arms

For these, 6082-T6 or 6061-T6 rods and bars are often selected due to their strength and machining performance, especially in above-waterline applications.

6.3 Outfitting & Equipment Mounting

- Brackets and mounting rails for equipment and piping

- Handrail posts, guard frames, and safety barriers

- Davit and crane subframe reinforcement (subject to classification approval)

- Ladder frames and gangway skeletons

Using marine aluminum for these items helps maintain overall vessel stability by keeping weight low and centralized.

6.4 Small Craft & High-Speed Vessels

- RIB and patrol boat reinforcing ribs

- Catamaran cross-deck frames

- Foil, strut, and boarding structure frames (where aluminum is specified)

High-speed craft benefit from every kilogram saved; aluminum rod and bar provide stiff, lightweight frameworks that respond well to dynamic loading.

7. Design & Fabrication Considerations

7.1 Alloy Selection Guidelines

| Application Zone | Recommended Alloy(s) | Notes |

|---|---|---|

| Immersed / splash zone | 5083, 5086 | Highest priority: corrosion |

| Above waterline hull | 5083, 5086, 6082 | Balance of strength & weldability |

| Superstructure | 6082, 6061, 5083 | High strength, good machinability |

| Highly welded details | 5083, 5086 | Non-heat-treatable, no loss from PWHT |

7.2 Welding & Joining

- Processes: GMAW (MIG) and GTAW (TIG) with argon or Ar/He mixtures

- Typical Fillers:

- 5356 / 5183 / 5556 for 5xxx base metals

- 5356 or 4043 depending on design for 6xxx

- Avoid mixing 5xxx with 6xxx in highly critical welded regions unless welding procedures are carefully qualified.

7.3 Corrosion Control

- Avoid direct contact with carbon steel; use insulating washers, gaskets, or coatings

- Ensure proper drainage and ventilation to reduce crevice corrosion risk

- Consider anodizing or marine paint systems in aggressive service or for aesthetic requirements

8. Benefits for Vessel Owners & Builders

8.1 Operational Advantages

| Benefit | Impact |

|---|---|

| Lower structural weight | Reduced fuel consumption, higher payload |

| Extended service life | Lower lifecycle cost, fewer replacements |

| Simplified maintenance | Less rust treatment, easier inspection |

| Improved stability | Better trim and seakeeping, especially in small craft |

8.2 Fabrication & Project Benefits

- Fast processing: Cutting, drilling, and welding can be completed quickly with standard shipyard equipment

- Flexible design: Bar and rod can be easily combined with plate and extruded shapes to create optimized frameworks

- Supply consistency: Standardized alloys, sizes, and tempers simplify design and procurement

Marine aluminum rod and bar provide a robust and lightweight solution for marine frame reinforcement, offering:

- High strength-to-weight ratio for efficient structural design

- Excellent corrosion resistance in seawater environments

- Good weldability and fabricability for shipyard and field work

- Versatility across hulls, decks, superstructures, and outfitting

By selecting the appropriate marine-grade alloy and dimensions, designers and builders can achieve durable, low-maintenance frames that enhance vessel performance and reduce operating cost over the entire lifecycle.

For detailed alloy selection, custom dimensions, or classification-specific requirements, project-specific engineering consultation and standards review (e.g., DNV, ABS, LR, ISO) are strongly recommended.

Related Products

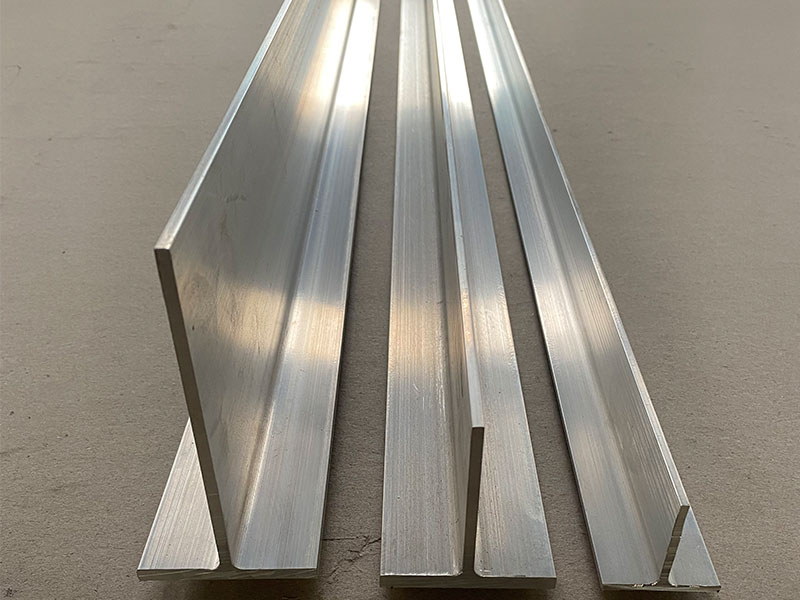

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

Marine Aluminum Angles for Custom Marine Equipment Fabrication

The marine industry evolves constantly, demanding innovation in materials to meet the challenges posed by harsh environments, stringent regulations, and above all, the need for efficiency and durability.

View DetailsMarine Aluminum Angles for Custom Marine Vessel Deck Parts

In the demanding maritime environment, the structural integrity and durability of vessel deck parts are paramount. Marine aluminum angles have emerged as a critical solution in the customization and reinforcement of these components.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details6061 Marine aluminum angles

6061 Marine Aluminum Angles are among the most popular and versatile aluminum alloy products used in marine and structural engineering applications. Renowned for their excellent strength, corrosion resistance, and machinability.

View DetailsMarine Aluminum Rod & Bar for Offshore Marine Project Design

Marine aluminum rod and bar products are core structural and functional materials in offshore and shipbuilding projects. They combine high strength, excellent corrosion resistance, and low weight.

View DetailsMarine Aluminum Round Bar for Marine Vessel Structural Support

Marine aluminum round bars are critical components specifically engineered to meet the demanding requirements of marine vessel structural support. Combining high strength, exceptional corrosion resistance, and excellent weldability.

View Details

Leave a Message