Aluminum perforated sheet for boat

Aluminum perforated sheet is a high-value material choice for boats and marine structures where weight control, corrosion resistance, drainage, airflow, and slip management matter as much as strength. Used across decks, steps, engine-room guards, ventilation panels, lockers, and interior fittings, a properly specified perforated sheet delivers long service life in saltwater while simplifying fabrication and maintenance.

Why Perforated Aluminum for Boats?

Marine environments combine salt spray, humidity, UV exposure, and mechanical vibration-conditions that punish heavy steels and unprotected materials. Perforated aluminum sheet solves multiple onboard problems at once:

- Weight reduction: helps fuel efficiency, speed, payload, and stability (lower topside weight improves handling).

- Corrosion resistance: marine-grade alloys withstand saltwater and galvanic challenges better than many alternatives.

- Drainage and ventilation: perforations allow water to escape and air to circulate-reducing trapped moisture and odor.

- Safety and cleanliness: better traction when paired with embossed surfaces or anti-slip treatments; easy wash-down.

- Design flexibility: thousands of hole patterns, open area options, and finishing styles for functional or decorative goals.

Common Marine Alloys and Why They Matter

Not all aluminum is "marine grade." For boat use, selection typically centers on 5xxx (Al-Mg) and 6xxx (Al-Mg-Si) alloys. Each has a different balance of corrosion resistance, formability, and strength.

Recommended Alloy Options (Marine-Focused)

| Alloy / Temper | Category | Strengths | Best-Fit Boat Uses | Notes |

|---|---|---|---|---|

| 5052-H32 | 5xxx | Excellent corrosion resistance, very good formability | Deck drains, lockers, interior panels, light platforms | One of the most popular perforated sheet choices |

| 5083-H111 / H321 | 5xxx | Very high corrosion resistance, higher strength | Exterior panels near splash zones, heavier-duty grilles | Premium marine alloy; cost higher, availability varies |

| 5086-H32 | 5xxx | Strong, marine-proven, good weldability | Steps, walkways, structural covers | Common in North American marine fabrication |

| 6061-T6 | 6xxx | High strength, good machinability | Frames behind perforated panels, supports, brackets | Perforated 6061 can crack in tight forming; consider bend radius |

Plant-floor guidance: For most perforated sheet panels that require bending or rolling, 5052-H32 is the safest default. If the panel sits in aggressive splash zones and needs more mechanical margin, upgrade to 5083/5086 where available.

Chemical Composition (Typical Ranges)

Chemical composition affects corrosion behavior, weld response, and mechanical stability. Verify mill test certificates (MTC) for each batch.

5052 (Al-Mg) - Typical Composition

| Element | Mg | Cr | Si | Fe | Cu | Mn | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 2.2–2.8 | 0.15–0.35 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.15 | Balance |

5083 (Al-Mg-Mn) - Typical Composition

| Element | Mg | Mn | Cr | Si | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 4.0–4.9 | 0.4–1.0 | 0.05–0.25 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.25 | ≤0.15 | Balance |

6061 (Al-Mg-Si) - Typical Composition

| Element | Mg | Si | Cu | Cr | Fe | Mn | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.8–1.2 | 0.4–0.8 | 0.15–0.40 | 0.04–0.35 | ≤0.70 | ≤0.15 | ≤0.25 | ≤0.15 | Balance |

Mechanical Properties (Typical)

Perforations reduce net section and change load distribution. Use these values for material baseline, then apply design factors based on open area and pattern.

| Alloy / Temper | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Notes for Marine Panels |

|---|---|---|---|---|

| 5052-H32 | ~160–190 | ~210–260 | ~8–12 | Excellent for forming perforated parts |

| 5083-H111/H321 | ~145–230 | ~275–330 | ~10–16 | Strong + corrosion resistant; good for exterior |

| 5086-H32 | ~200–240 | ~290–340 | ~8–14 | Common for walkable structures |

| 6061-T6 | ~240–280 | ~290–320 | ~8–12 | Strong; watch bend radius near perforations |

Hole Patterns: Performance Trade-Offs That Matter on a Boat

Choosing a perforation style is more than appearance-it changes grip, airflow, stiffness, and cleaning behavior.

Common Patterns and Typical Open Area

| Pattern Type | Typical Hole / Pitch Examples | Typical Open Area | Strength & Stiffness | Where It Works Best |

|---|---|---|---|---|

| Round, 60° staggered | 5 mm hole / 8 mm pitch | ~35–45% | Best stiffness per open area | Vent panels, guards, general-purpose |

| Round, straight line | 6 mm / 9 mm | ~30–40% | Slightly less stiff than staggered | Aesthetic panels, partitions |

| Slotted (long holes) | 4×20 mm slots | ~20–45% | Directional stiffness (weak across slot) | Drainage channels, air intakes |

| Square/rectangular | 10×10 mm | ~30–50% | More aggressive edges | Grids, decorative screens |

Boat-specific selection tips

- Deck drainage & wet zones: moderate open area (~30–40%) to avoid "oil canning" while still draining.

- Engine room ventilation: higher open area (40–55%) to reduce pressure drop, paired with backing mesh if needed.

- Guards and covers: staggered round holes balance rigidity and safe handling.

Technical Specifications Customers Should Request

A good marine perforated sheet quote should define alloy, temper, thickness, hole/pitch, finish, and tolerances. Below is a practical specification set used in marine fabrication.

Typical Technical Specification Range (Marine Supply)

| Parameter | Common Range | Recommendation for Boats |

|---|---|---|

| Sheet thickness | 1.5–6.0 mm | 2.0–4.0 mm for most panels; thicker for walkways |

| Sheet size | 1000×2000, 1220×2440, custom | Choose to minimize seams and welding |

| Alloy / Temper | 5052-H32, 5083-H111/H321, 5086-H32, 6061-T6 | Default 5052-H32 unless higher duty required |

| Hole diameter | 2–20 mm | 4–8 mm is versatile |

| Pitch (center-to-center) | 4–30 mm | Select to control open area and stiffness |

| Open area | 15–60% | 30–45% is a strong marine "sweet spot" |

| Edge margin | 5–25 mm | Larger margins improve strength at fasteners |

| Flatness | Defined by standard/spec | Important for covers and hatches |

| Finish | Mill, anodized, powder coat, PVDF | Anodizing/powder for appearance + cleanability |

| Protective film | Optional | Recommended for cosmetic panels during fabrication |

Corrosion Resistance: What "Marine Grade" Really Means

Marine alloys resist saltwater primarily through stable oxide film formation and alloy chemistry (especially magnesium content in 5xxx). Still, real-world corrosion performance depends on installation details:

- Avoid galvanic couples: isolate aluminum from stainless steel/bronze with non-conductive washers, gaskets, or coatings.

- Choose compatible fasteners: 316 stainless is common; design to reduce crevice corrosion.

- Seal crevices and trapped zones: perforations help ventilation, but edges and lap joints can trap salt.

- Use the right coating: anodizing improves surface hardness and aesthetics; powder coat adds barrier protection (prep quality is critical).

Applications on Boats (Practical Use Cases)

| Boat Area | Function | Why Perforated Aluminum Works |

|---|---|---|

| Deck plates & drainage covers | Drain water, reduce pooling | Open area + corrosion resistance + lightweight |

| Steps, ladders, platforms | Traction + water shedding | Perforations reduce slip risk and dry faster |

| Engine room air intake/exhaust panels | Ventilation, safety guarding | High airflow with mechanical protection |

| Cabin partitions & decorative panels | Style + airflow | Clean look, easy to maintain |

| Locker and battery compartment panels | Vent gas/heat | Improves safety and reduces moisture buildup |

| Speaker grilles & electronics covers | Protection + acoustics | Controlled open area and good machinability |

Customer Benefits: What You Get in Service

- Lower operating cost: reduced weight can translate to fuel savings and easier handling.

- Longer life in salt exposure: proper marine alloy choice reduces pitting and surface degradation.

- Cleaner, drier spaces: ventilation and drainage reduce mold and corrosion in hidden compartments.

- Faster fabrication: easy cutting, bending (especially 5052), riveting, and welding with established marine practices.

- Customizable performance: hole pattern can be tuned for airflow, privacy, noise, and strength.

Ordering Checklist (Quick and Effective)

Provide these details to avoid mismatches and rework:

| Item | Example to Specify |

|---|---|

| Alloy / temper | 5052-H32 (marine interior/exterior general) |

| Thickness | 3.0 mm |

| Pattern | Round holes, 60° staggered |

| Hole / pitch | 6 mm hole, 9 mm pitch |

| Edge margin | 15 mm on all sides |

| Sheet size | 1220×2440 mm |

| Finish | Anodized (clear) or powder-coated (marine system) |

| Intended use | Walkable / non-walkable, splash zone, ventilation panel |

Closing Note

An aluminum perforated sheet for boat is not just a metal panel with holes-it's a tuned marine component. By matching alloy + temper + perforation geometry + finish to the real onboard environment, you get a lightweight part that drains, breathes, resists corrosion, and stays serviceable for years with minimal upkeep.

Related Products

Marine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsRelated Blog

Aluminium Coil Or Sheet For Boat

When it comes to maritime design and construction, selecting materials that balance strength, weight, and corrosion resistance is critical.

View DetailsMarine grade aluminum sheet 5083 for ship building

Marine environments punish materials with salt spray, humidity, cyclic loads, and constant maintenance pressure.

View DetailsAluminium sheet 8mm alloy 5052 h112 for boat

When selecting materials for marine applications, especially in boat building, the balance between strength, corrosion resistance, and workability is crucial. Aluminium sheet 8mm thick made from alloy 5052 in temper H112 epitomizes this balance.

View DetailsAluminum Sheet 5083 5086 5754 for Fishing Boat

Aluminum sheets 5083, 5086, and 5754 are widely recognized alloys in the marine industry, known for their excellent corrosion resistance, mechanical strength, and durability.

View Details5083 10mm Thickness Aluminum coil for Boat

5083 10mm Thickness Aluminum Coil for Boat: When "Strength" Also Means "Staying Beautiful at Sea"In boatbuilding, material decisions are rarely about a single property.

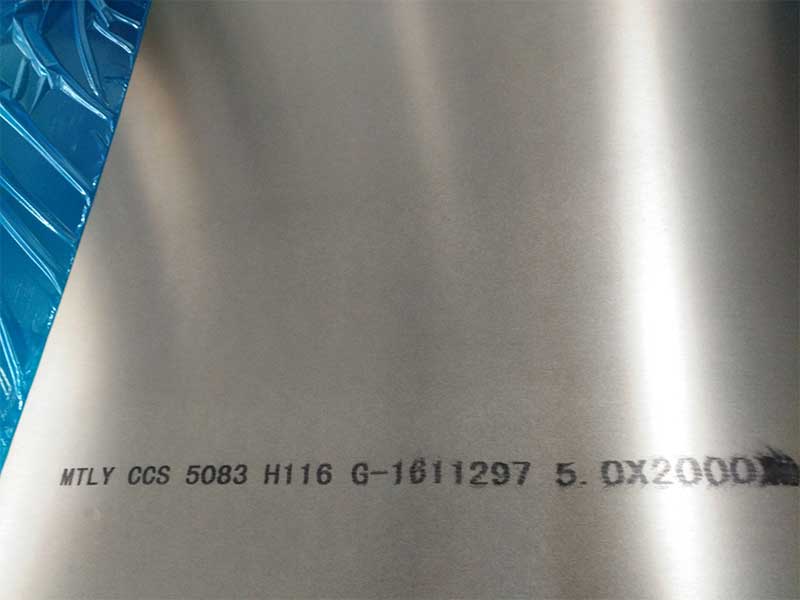

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details

Leave a Message