5052 Marine Aluminum Tubes for Seawater Tolerant Boat Parts

5052 marine aluminum tubes are a go-to choice for boat builders and marine fabricators who need tubing that resists seawater corrosion, welds cleanly, and stays dependable under vibration and daily service. Built on an aluminum–magnesium chemistry, 5052 offers an excellent balance of strength, formability, and long-term durability in coastal and offshore environments-without the weight, rust, or maintenance burden of many steel alternatives.

From console frames and T-top structures to railings, supports, and light structural tubing, 5052 tubes deliver practical performance where salt spray, humidity, and galvanic risk are part of normal life.

Why 5052 Tubes Perform So Well in Marine Service

5052 is an Al-Mg alloy known for strong resistance to marine atmospheric corrosion and splash-zone exposure. Its magnesium content helps create a stable oxide film, slowing pitting and general corrosion in chloride-rich environments. In real fabrication shops, 5052 is valued because it cuts, bends, notches, and welds with fewer surprises than many higher-strength alloys.

features at a glance

| Feature | What it means for boat parts |

|---|---|

| Seawater-tolerant corrosion resistance | Suitable for salt air, spray, and washdown environments |

| Excellent weldability | Reliable TIG/MIG welding for frames, supports, and brackets |

| Good formability | Bends and forms well for rails, hoops, and curved members |

| Solid fatigue and vibration behavior | Practical durability for trailering, chop, and engine vibration |

| Lightweight | Improves fuel efficiency and handling vs. steel components |

| Clean surface options | Mill finish or anodized-friendly appearance for visible structures |

Common Applications on Boats and Near-Seawater Equipment

5052 marine aluminum tubes are widely used for non-pressure and light-to-medium structural applications. They are especially popular in small craft, workboats, pontoons, and coastal equipment where corrosion resistance is more valuable than maximum tensile strength.

| Application area | Typical tube use cases |

|---|---|

| Deck and console structures | Console frames, instrument mounts, seat frames |

| Tops and overhead systems | T-top frames, bimini structures, canopy supports |

| Safety and handling | Grab rails, handrails, bow rails, ladder tubing |

| Utility and storage | Rod holders, rack frames, equipment stanchions |

| Coastal infrastructure | Dock accessories, shoreline frames, brackets, enclosures |

Design note: 5052 is not typically selected for high-pressure hydraulic lines or critical pressure vessels. For highly stressed structural members where peak strength is the priority, designers may compare against 6061-T6 tubing; for heavy seawater immersion or specialized corrosion demands, 5083/5086 may be considered. For many boat-part tubes, 5052 hits the sweet spot of corrosion resistance, forming, and weldability.

Alloy and Temper Options for Marine Tubing

5052 tubes are commonly supplied in tempers that match fabrication needs. The "H" tempers indicate strain-hardened conditions, often used when you want more strength than fully annealed material while keeping reasonable formability.

| Temper | Typical characteristics | Where it fits best |

|---|---|---|

| O (Annealed) | Maximum ductility, easiest bending/forming | Tight-radius bends, complex formed parts |

| H32 | Strain-hardened and stabilized, balanced strength/formability | General marine tube fabrication, welded frames |

| H34 | Higher strength than H32, slightly reduced formability | Straighter members, less severe bending |

Chemical Composition (5052 Aluminum, Typical Limits)

5052's performance comes from its controlled magnesium content and low levels of copper and other elements that can reduce corrosion resistance in marine exposure.

| Element | Typical specification range (wt. %) |

|---|---|

| Magnesium (Mg) | 2.2–2.8 |

| Chromium (Cr) | 0.15–0.35 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.10 |

| Aluminum (Al) | Balance |

Practical takeaway: low copper content supports better corrosion behavior near seawater, while magnesium boosts strength and marine durability.

Mechanical Properties (Typical Values)

Mechanical values vary by tube size, wall thickness, and specific production method. The table below reflects commonly referenced typical properties for marine fabrication planning.

| Property | 5052-O (Typical) | 5052-H32 (Typical) | 5052-H34 (Typical) |

|---|---|---|---|

| Ultimate tensile strength | ~170–210 MPa | ~230–260 MPa | ~250–290 MPa |

| Yield strength | ~70–100 MPa | ~160–200 MPa | ~180–220 MPa |

| Elongation (50 mm) | ~18–25% | ~10–16% | ~8–14% |

| Brinell hardness | ~45–55 HB | ~60–70 HB | ~65–75 HB |

Tube Technical Specifications (Typical Supply Range)

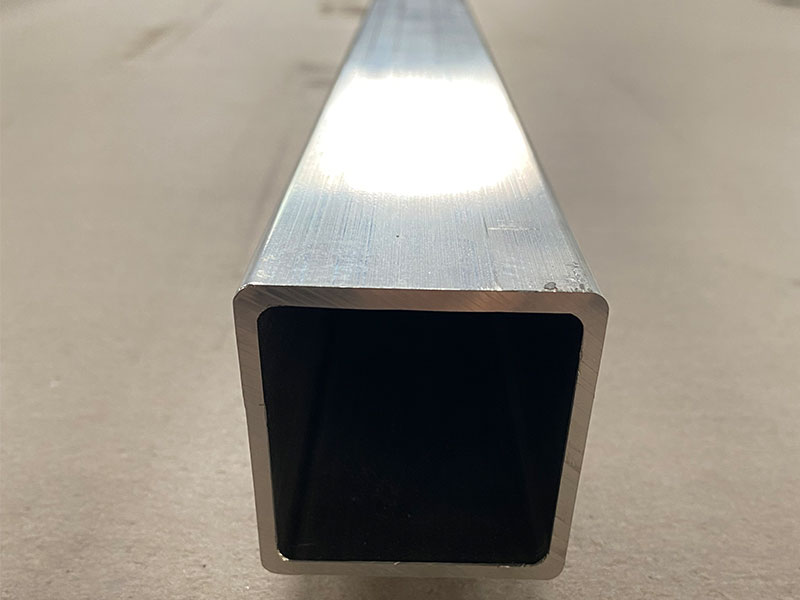

5052 marine aluminum tubes can be produced as round, square, or rectangular profiles, with sizing and tolerances depending on the mill, extrusion route, and finishing requirements.

| Parameter | Typical options |

|---|---|

| Tube shapes | Round, square, rectangular |

| Outer diameter (round) | Commonly 10–200 mm (custom possible) |

| Wall thickness | Commonly 1.0–10.0 mm |

| Length | Commonly 3–6 m (cut-to-length available) |

| Temper | O, H32, H34 |

| Supply form | Straight lengths (standard), some sizes coilable by request |

| Surface finish | Mill finish, brushed/polished (optional), anodizing-ready |

| Fabrication compatibility | TIG/MIG weldable, bendable, machinable |

Ordering tip: for welded assemblies, specify consistent temper and wall thickness across the build to reduce distortion variability and simplify weld procedure repeatability.

Corrosion Resistance in Marine Environments

5052 is widely recognized for strong performance in marine atmospheres, splash zones, and general salt exposure. Like all aluminum alloys, it benefits from thoughtful design that avoids crevices and stagnant saltwater traps. Where seawater can pool inside a tube, sealing or drainage is recommended to reduce internal corrosion and salt crystallization.

| Exposure condition | 5052 tube behavior | Recommended practice |

|---|---|---|

| Salt air / coastal atmosphere | Excellent resistance | Periodic rinse; avoid trapped deposits |

| Spray / splash zone | Very good resistance | Use smooth finishes; minimize crevices |

| Dissimilar-metal contact | Risk of galvanic corrosion | Isolate with polymer washers, sealants, coatings |

| Stagnant saltwater trapped in joints | Localized attack possible | Provide drain holes, seal ends, vent where needed |

Fabrication Notes: Welding, Bending, and Finishing

5052 tubes are known for friendly shop behavior, especially in welded marine frames.

| Process | What to expect with 5052 tubes | Practical guidance |

|---|---|---|

| TIG/MIG welding | Smooth weldability, good crack resistance | Use clean prep; choose marine-suitable filler per procedure |

| Bending | Good bend performance, especially in O or H32 | Confirm bend radius; use proper mandrels for thin walls |

| Machining | Machinable, though not as free-cutting as some alloys | Use sharp tooling; control heat and chip evacuation |

| Anodizing | Generally anodizes well | Uniform surface prep helps cosmetic consistency |

| Painting/powder coat | Bonds well with correct prep | Use conversion coating/primer system designed for marine aluminum |

Quality, Traceability, and What Customers Should Specify

Marine customers often need consistent tubing for repeat production and clean assembly fit-up. Clear specifications reduce lead time and rework.

| Customer requirement | What to specify |

|---|---|

| Dimensional consistency | OD/width/height, wall thickness, straightness limits |

| Corrosion-driven purchasing | Confirm alloy 5052 and temper (H32 is common) |

| Welding performance | Preferred filler compatibility and post-weld finish requirements |

| Cosmetic needs | Surface finish level, protection film, anodize/powder-coat readiness |

| Documentation | Material test report, heat/lot traceability if required |

5052 marine aluminum tubes are a smart, seawater-tolerant tubing solution for boat parts that must resist corrosion, weld reliably, and maintain long service life with minimal upkeep. With flexible temper options, practical strength, and excellent forming characteristics, 5052 tubing supports everything from rails and frames to brackets and marine hardware structures-keeping boats lighter, cleaner, and easier to maintain.

5052 marine aluminum tubes offer seawater-tolerant corrosion resistance, excellent weldability, and reliable strength for boat parts like rails, T-tops, frames, and supports. Explore chemical composition, tempers, mechanical properties, and tube specifications for marine fabrication.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Marine Industrial Use

5052 marine aluminum tubes are widely used in shipbuilding, offshore structures, and marine equipment due to their excellent corrosion resistance in seawater, medium‑high strength, and good forming/welding performance.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available.

View Details5052 Marine Aluminum Tubes for High Performance Boat Structures

When it comes to high-performance boat structures, the strength, weight, and durability of materials matter enormously. One of the most favored materials in the marine industry is **5052 Marine Aluminum Tubes.

View Details

Leave a Message