Aluminium sheet marine

Marine aluminum sheets are crucial components in the maritime industry, providing durability, lightweighting, and corrosion resistance for various applications.

Functions of Marine Aluminum Sheets

Marine aluminum sheets serve several important functions, including:

Corrosion Resistance: Aluminum naturally forms a metallic oxide layer that protects the material from corrosive effects, particularly from seawater environments.

Structural Lightweighting: Due to its low density compared to steel, aluminum reduces the overall weight of marine structures. This property enhances fuel efficiency and can increase payload capacity.

Workability: Aluminum sheets can be easily fabricated into specific shapes and sizes, making them well-suited for custom marine applications.

Thermal Conductivity: Better thermal conductivity allows for professional applications like heat exchangers and other components sensitive to temperature control.

Aesthetic Versatility: Marine aluminum can be finished or anodized, offering performance without sacrificing aesthetics.

Applications of Marine Aluminum Sheets

Marine aluminum sheets are utilized in various applications such as:

Boat and Shipbuilding: Hulls, decks, and various structures within marine vessels where strength and low weight are factors of critical importance.

Marine Equipment: Components for marine machinery, fishing equipment, and pontoons.

Marine Architecture: Features in design including gangways, bridges, and walkways.

Transportation: Lightweight containers and packages for marine transportation, designed to withstand demanding conditions.

Wind Power in Marine Locations: Utilization in offshore wind turbines owing to seawater his resilience.

Technical Details

To give you a clear of the specifics, below is a table highlighting essential technical details relating to marine aluminum sheets:

| Parameter | Details |

|---|---|

| Material Comprised | Aluminum Alloys (commonly 5000 and 6000 series) |

| Temper | H111, H32, H34, and S81 for specific applications |

| Thickness range | 1.0 mm – 10 mm |

| Width | Up to 2500 mm depending on the supplier |

| Length | Standard lengths 6000 mm or customizable |

| Weight | Approximately 2.7 g/cm³ |

Chemical Composition

The specific alloying constituents greatly affect the material's properties. The table below depicts the chemical composition typically found in 5000 and 6000 series marine-grade aluminum sheets:

| Alloy | Al | Mg (magnesium) | Zn (zinc) | Si (silicon) | Mn (manganese) | Cu (copper) | Fe (iron) |

|---|---|---|---|---|---|---|---|

| 5005 | 95.7% | 0.5% | 0.05% - 0.2% | 0.1% - 0.7% | 0.1% - 0.4% | 0.1% | 0.5% |

| 5083 | 91.5% | 4.0% | 0.2% | 0.0% | 0.4% - 1.0% | 0.1% | 0.4% |

| 6061 | 95.4% | 0.9% - 1.3% | 0.25% – 0.6% | 0.5% - 0.6% | 0.15% | 0.15% | 0.7% |

Alloy Tempering Conditions

The tempering of the aluminum sheets significantly enhances their material properties; below table outlines the conditions typical for closer decidable choices:

| Temper | Temper Condition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| H111 | Strain-hardened, passed reduction | 135 | 100 |

| H32 | Solution heat treated, further strain-hardened | 290 | 240 |

| H34 | Solution heat treated, further strain-hardened but precluded from revers periods | 295 | 215 |

| S81 | As-received shorter hardness treatments, slight unstable resist | 175 - 224 | 125 |

Applications Standards

Several standards dictate the manufacturing and testing of marine aluminum:

| Standard Organization | Standard Identifier | Description |

|---|---|---|

| ASTM | ASTM B928 | Standard Specification for High Magnesium Aluminum Alloys for Marine Applications |

| ISO | ISO 6362 | Wrought Aluminium and Aluminium Alloys - Sheets and Plates - General Technical Delivery Conditions |

Related Products

Marine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsRelated Blog

5052 5083 5086 Marine Grade Aluminium Sheet for Boat Building

Marine-grade aluminum is essential for constructing durable, lightweight vessels capable of withstanding harsh marine environments. In particular, 5052, 5083.

View DetailsCustom shape boat aluminum sheet 5083 h22 h111 h112 h116 h321

In the maritime industry, the need for robust, lightweight, and corrosion-resistant materials is paramount. One material that consistently meets these requirements is Marine Aluminum.

View Details7075 T6 Aluminum Sheet For Boat

When it comes to selecting the ideal material for marine applications, especially boats, durability, corrosion resistance, and strength are non-negotiable. Among various marine-grade aluminum alloys.

View Details5052 5083 marine grade aluminium sheet for boat

Marine grade aluminium alloys 5052 and 5083 are among the most widely used non-heat-treatable alloys for shipbuilding, small vessels, and marine components. They combine good corrosion resistance in seawater, excellent weldability and formability.

View DetailsAluminium sheet marine

Marine aluminum sheets are crucial components in the maritime industry, providing durability, lightweighting, and corrosion resistance for various applications.Functions of Marine Aluminum SheetsMarine aluminum sheets serve several important functions.

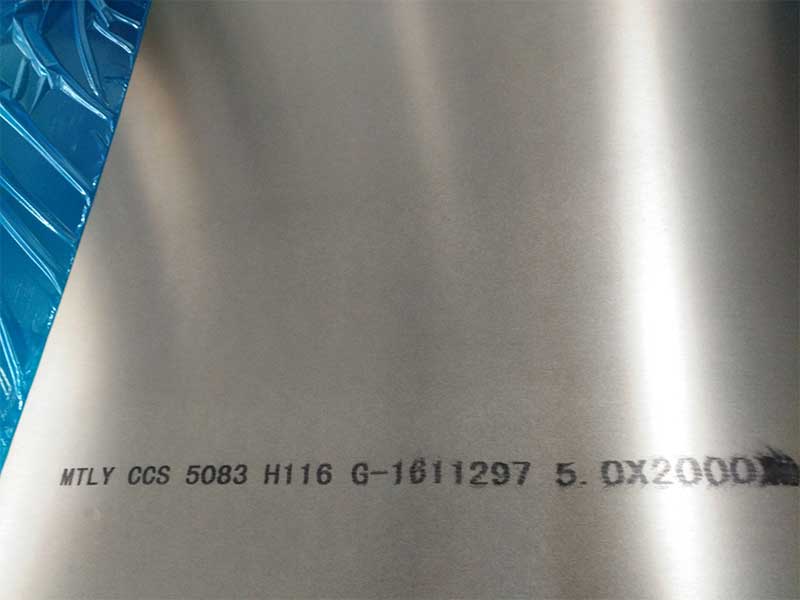

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details

Leave a Message