5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical. 5083 Marine Aluminum Angles have become the preferred choice for heavy-duty offshore boat hulls thanks to their exceptional strength, corrosion resistance, and weldability.

5083 is an alloy in the 5xxx series distinguished primarily by its magnesium content (4.5%-5.6%) which imparts superior corrosion resistance and strength, especially in saltwater environments. This makes it particularly suitable for marine applications, where exposure to salt spray, seawater, and changing weather conditions demands robust materials.

Chemical Composition (wt.%)

| Element | Content Range |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 4.5 - 5.6 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Silicon (Si) | ≤ 0.4 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Features of 5083 Marine Aluminum Angles

1. Exceptional Corrosion Resistance

Hulls in the marine environment are constantly at risk of degradation from saltwater corrosion. The high magnesium content and chromium addition in 5083 alloy create a protective oxide layer that provides outstanding corrosion resistance to seawater, salt spray, and industrial atmospheres, thus extending the lifespan of boat hull structures.

2. Superior Mechanical Strength

5083 alloy offers an excellent strength-to-weight ratio, combining lightweight aspects of aluminum with enhanced tensile and yield strength critical for offshore applications. This results in structural angles that can manage heavy loads while minimizing added weight to the vessel.

| Mechanical Property | Value (Typical) |

|---|---|

| Tensile Strength (MPa) | 290 - 350 |

| Yield Strength (MPa) | 145 - 215 |

| Elongation (%) | 12 - 20 |

| Brinell Hardness (HB) | 75 - 90 |

3. Excellent Weldability & Fabrication

Marine aluminum hull construction often involves extensive welding and bending. 5083 angles offer weldability comparable to mild steel with minimal degradation of corrosion resistance and mechanical properties post-welding. Furthermore, this alloy maintains excellent formability which facilitates bending, flanging, and other deformation processes.

4. Lightweight and High Toughness

The angles contribute to overall weight reduction of offshore boats without compromising toughness. This aids in improved fuel efficiency, higher payload capacities, and easier vessel handling during deployment and maintenance.

Specifications of 5083 Marine Aluminum Angles

| Parameter | Specification Range |

|---|---|

| Thickness (mm) | 3 - 25 |

| Width of Legs (mm) | 20 - 150 |

| Length (m) | 3 - 6 |

| Standard | AMS-QQ-A-250/9, ASTM B221 |

| Surface Treatment | Mill finish, anodize or powder coat (optional) |

| Temper | O (annealed), H111 (strain hardened) |

Applications in Heavy Duty Offshore Boat Hulls

5083 marine aluminum angles are extensively used in various structural and reinforcement roles in heavy-duty offshore vessels due to their reliable structural integrity and corrosion resistance:

Working with 5083 marine aluminum angles for offshore boat hulls is a constant reminder of the delicate balance between strength and corrosion resistance. We're not just dealing with a material; we're building the backbone of vessels facing relentless saltwater assault. The grain structure of the 5083, its superior weldability, and the specific alloying elements are crucial conversations during fabrication. I've seen firsthand how even minor variations in welding parameters – too much heat, insufficient penetration – can compromise the structural integrity, especially in areas subjected to high stress like the hull's chines. Getting it right means meticulous attention to detail, rigorous quality control, and a deep of the material's behavior under pressure, both mechanical and environmental.

Beyond the technical specifications, I've also developed an appreciation for the human element. The boatbuilders we supply rely on the consistent quality of our angles to build durable, safe vessels. Knowing that our work contributes to the safety of crews navigating harsh marine environments is immensely satisfying. However, the increasing demand for lighter yet stronger hulls pushes us to continuously refine our processes and explore innovative welding techniques to meet the demands for fuel efficiency. It's a challenge, but witnessing a completed hull built with our materials – a testament to the collaborative effort from design to fabrication – makes all the hard work worthwhile.

1. Hull Frame Structures

Angles serve as primary reinforcement members of hull frames, stringers, and bulkheads, providing rigid support against high impact stresses and harmonic motion caused by ocean waves.

2. Support Brackets and Mountings

Used as mounting angles and brackets inside hull assemblies to secure machinery, equipment, and ballast tanks in deep-sea conditions requiring vibration resistance and strong load-bearing capability.

3. Deck and Superstructure Elements

In offshore platforms and vessels, these aluminum angles offer lightweight yet robust framing for deck supports, guardrails, and ladders where exposure to maritime weather is high.

4. Fishing and Specialized Working Boat Construction

Given their resistance against biofouling and corrosive waters, 5083 angles are popular for hulls of trawlers, patrol boats and exploration crafts that demand enhanced durability.

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

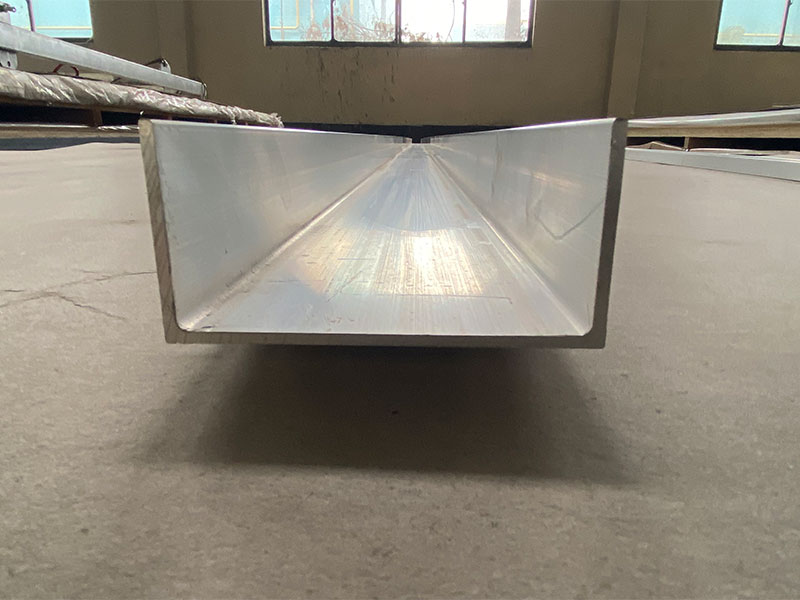

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

5083 Marine Aluminum Channels for Coastal Marine Engineering Projects

In the realm of coastal marine engineering, material selection is crucial for ensuring the durability, performance, and safety of structures exposed to harsh sea environments.

View Details5083 Marine Aluminum Channels for Offshore Platform Construction

In the demanding world of offshore platform construction, material selection forms the backbone of structural integrity, durability, and performance. With increasing emphasis on lightweight and corrosion-resistant materials.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details

Leave a Message