Marine Aluminum I-Beams are specially engineered structural components designed to meet the rigorous demands of marine and offshore environments. Combining the strength and durability of aluminum alloys with the classic I-beam shape, these beams provide excellent load-bearing capacity while maintaining lightweight properties crucial for marine applications. They serve as essential structural elements in shipbuilding, offshore platforms, coastal infrastructure, and other maritime engineering projects.

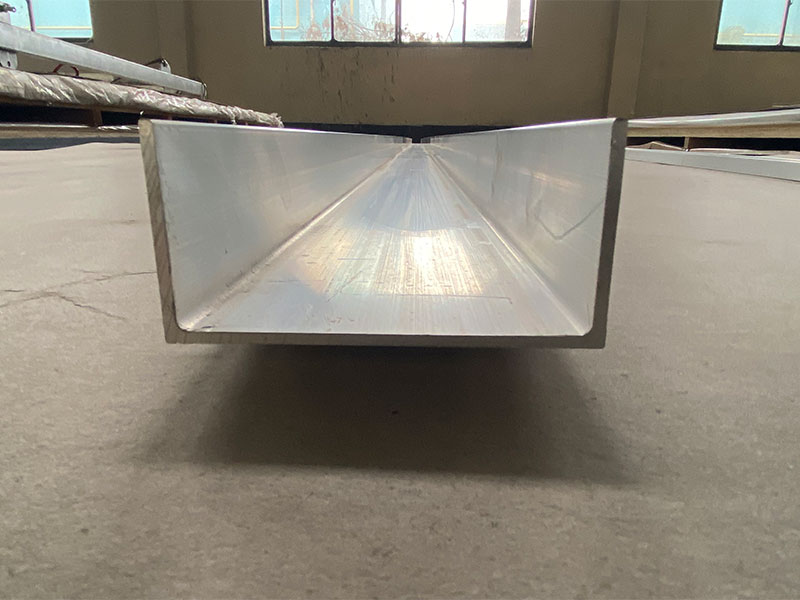

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction. The I-beam geometry offers superior bending and shear strength per unit weight compared to many other shapes, ensuring efficient support of structural loads with reduced material usage and weight.

Produced primarily through extrusion or rolling and fabricated with precision to tight tolerances, Marine Aluminum I-Beams come in a variety of sizes and thicknesses to suit a broad range of engineering requirements.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Marine-Grade Aluminium Alloys | Typically 5xxx series alloys (5083, 5086) and 6xxx series (6061) with proven corrosion resistance | Long lifespan in marine environments and reduced maintenance costs |

| I-Beam Cross-Section Design | Optimized shape for maximum bending strength and stiffness with minimum weight | Superior load support with reduced structural weight |

| Lightweight | Density around 2.66 g/cm³, significantly lighter than steel | Improved fuel efficiency and ease of handling |

| Excellent Corrosion Resistance | Aluminum oxide layer combined with alloying elements protects against seawater corrosion | Reduced risk of pitting and crevice corrosion |

| Versatile Size Range | Available in standard and custom dimensions with varied flange widths and web thicknesses | Flexibility to meet specific project design and load criteria |

| Good Fabrication Properties | Can be cut, welded, drilled and formed with common marine fabrication methods | Simplifies installation and onsite modifications |

Common Marine Aluminum Alloys for I-Beams

| Alloy | Key Composition & Advantages | Suitable Marine Applications |

|---|---|---|

| 5083 | Mg 4.0-4.9%, excellent corrosion resistance, moderate strength | Ship hulls, offshore structural support |

| 5086 | Mg 4.0-4.9%, increased strength, superior weldability | Load-bearing beams in vessels and platforms |

| 6061 | Mg 0.8-1.2%, Si 0.4-0.8%, increased strength with anodizing option | High strength frame members, machined components |

Mechanical Properties (Typical Values)

| Property | 5083-H321 | 5086-H32 | 6061-T6 |

|---|---|---|---|

| Tensile Strength (MPa) | 300 – 350 | 275 – 350 | 310 – 350 |

| Yield Strength (MPa) | 145 – 215 | 145 – 230 | 270 – 300 |

| Elongation (%) | 10 – 18 | 12 – 18 | 8 – 12 |

| Density (g/cm³) | 2.66 | 2.66 | 2.70 |

Manufacturing Process

Extrusion or Rolling: Marine Aluminum I-Beams are produced through precision extrusion (for custom profiles) or rolling processes, ensuring tight tolerances and consistent cross-section.

Aging and Tempering: Depending on alloy and desired mechanical properties, heat treatment or strain hardening (e.g., T6 temper for 6061) are applied.

Surface Preparation: Channels often come with a mill finish; anodized, painted, or powder-coated finishes are available to enhance corrosion resistance and aesthetics.

Cutting and Fabrication: I-beams can be cut to length, drilled, welded, and formed to meet exact construction requirements.

Typical Applications

Structural frameworks and support beams in shipbuilding and yacht manufacturing

Load-bearing elements on offshore oil and gas platforms and wind farms

Bridge supports, piers, and docks in coastal civil engineering projects

Hull stiffeners and deck reinforcements in various marine vessels

Marine cranes, hoists, and cargo handling equipment

Custom marine engineering projects requiring high strength and lightweight components

Advantages Compared to Other Materials

| Attribute | Marine Aluminum I-Beams | Steel I-Beams | Stainless Steel I-Beams |

|---|---|---|---|

| Corrosion Resistance | Excellent in marine environments | Poor without protective coatings | Excellent but heavier and costlier |

| Weight | Lightweight (~2.66 g/cm³) | Heavy (~7.85 g/cm³) | Heavy (~7.7–8.0 g/cm³) |

| Maintenance | Low, natural corrosion resistance | High, corrosion coatings required | Moderate due to corrosion resistance |

| Fabrication Ease | Easily welded and machined | Moderate; heavier fabrication | Difficult and costly machining |

| Lifecycle Cost | Low due to durability and maintenance | High due to corrosion and wear | Moderate to high |

Maintenance Recommendations

To ensure long-lasting performance of Marine Aluminum I-Beams:

Routine Cleaning: Periodically wash with fresh water to remove salt deposits and marine fouling.

Inspection: Regularly examine for mechanical damage, scratches, or signs of corrosion, especially near welds and contact points.

Surface Protection: Consider anodizing or marine-grade coatings for high-exposure environments.

Avoid Contact with Dissimilar Metals: Use insulators to prevent galvanic corrosion where aluminum interfaces with other metals.

Marine Aluminum I-Beams offer an excellent solution for marine structural applications requiring a combination of high strength, excellent corrosion resistance, and lightweight features. Their versatility, durability, and fabrication flexibility make them vital for shipbuilders, offshore engineers, and coastal infrastructure developers seeking reliable, long-lasting structural members in demanding saltwater environments.

For customized specifications, technical support, and project consultation, please contact our experienced marine metals specialists who can help tailor the ideal Marine Aluminum I-Beam solution to your needs.