5083 Marine Aluminum Round Bar for Custom Boat Hull Design

Designing the perfect boat hull involves a harmony of creativity, functionality, and the right materials. When it comes to marine engineering, 5083 Marine Aluminum Round Bar stands tall, due to its strength, corrosion resistance, and welding capabilities.

What Sets 5083 Marine Aluminum Apart?

5083 marine aluminum is a magnesium aluminum alloy, prized for its ability to resist corrosion, particularly in seawater environments. This characteristic makes it ideal for marine applications, ensuring durability and longevity. When considering custom boat hulls, here are some distinctive features that make this alloy the preferred choice:

Excellent Corrosion Resistance: Thanks to its significant magnesium content, 5083 delivers supreme immunity against corrosion, especially in harsh marine environments.

High Strength-to-Weight Ratio: This lightweight alloy doesn't compromise on sturdiness, making it apt for specialized boat designs ranging from fishing boats to superyachts.

Weldability: It can be readily welded without weakening its strength or structural integrity. This opens a spectrum for intricate boat designs, allowing for more complex shapes to come together seamlessly.

Enhanced Formability: The malleability of 5083 facilitates the creation of unique hull designs without dependence on large casts or bulky fabrication processes.

Parameters and Technical Specifications of 5083 Marine Aluminum

Chemical Composition Table

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | 90.7 - 94.7 |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.40 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Zinc (Zn) | 0.25 (max) |

| Copper (Cu) | 0.10 (max) |

| Silicon (Si) | 0.25 (max) |

| Others | 0.15 each (max) |

Mechanical Properties at Room Temperature

| Property | Value |

|---|---|

| Ultimate Tensile Strength (UTS) | 335 MPa (min) |

| Yield Strength (YS) | 230 MPa (min) |

| Elongation (% in 50 mm) | 10-15% |

| Hardness (Brinell) | 70-110 HB |

Implementation Standards for 5083 Aluminum

The use of 5083 Aluminum complies with various industry standards, particularly in the marine sector. The primary standards include ANSI/AISI for material selection, ASA/ASTM guideline on aluminium extrusions, and various ISO standards, which dictate quality assurance practices and material procurement methods.

In custom boat hull designs, it's crucial to ensure the material fulfills these regulations, guarding against failures due to fatigue or undue corrosion over time. Always verify your material suppliers for compliance and certifications on:

- ISO 9001 Quality Management Systems

- DNV GL or Lloyd's Register Certification

Alloy Tempering, Processing Conditions, and Applications

Temper designations such as H116 (heat-treated) are vital in verifying how 5083 aluminum should be treated to obtain optimal strength and ductility levels. The H116 temper offers balance between toughness in unpredictable sea conditions and workability properly suited for high-stress marine environments.

Here are processing conditions that affect 5083's performance:

- Heating temperature during machining,

- Cooling rates after welding,

- Ans proper post-welding heat treatment rig,

Ensuring adequate guidelines on these processing stands makes every round bar solid enough to make the most daring hull designs feasible.

Practical Applications

Common applications include segmented hull plates, reinforced internal structures, and undercarriage supports of various marine vessels. The round bar option can further whet a designer’s appetite as it's amenable to turning and creating specialized fittings, providing your custom builds the robustness they demand.

Related Products

Marine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

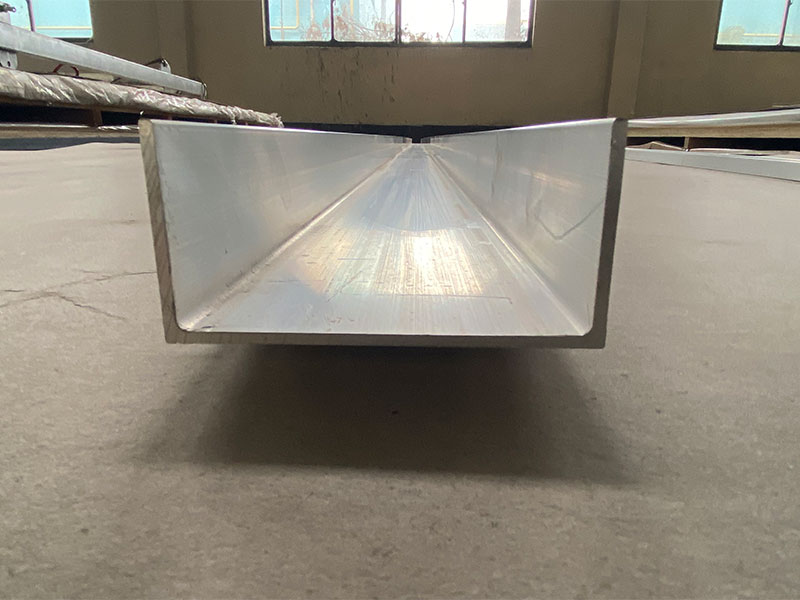

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

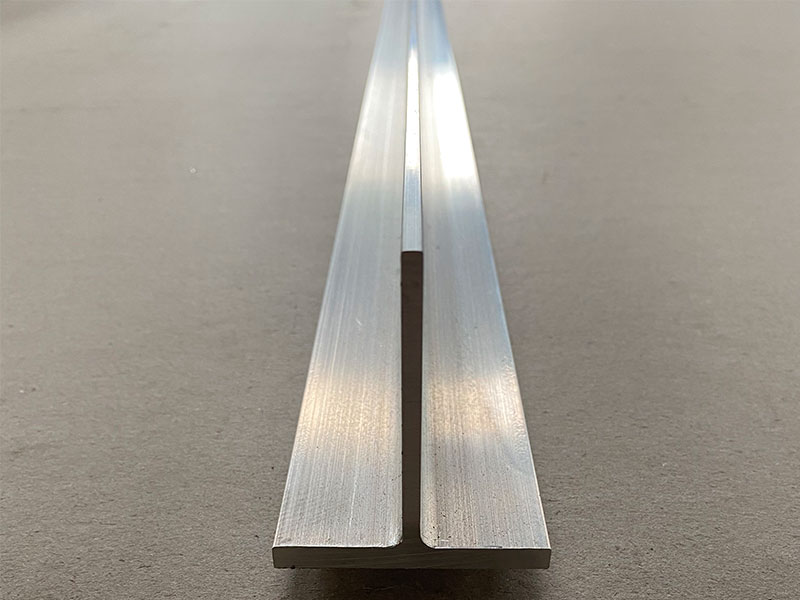

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

5083 Marine Aluminum Channels for Coastal Marine Engineering Projects

In the realm of coastal marine engineering, material selection is crucial for ensuring the durability, performance, and safety of structures exposed to harsh sea environments.

View Details5083 Marine Aluminum Z Shaped Sections for Boat Frame and Hull Customization

When it comes to marine structures, the choice of materials is crucial for durability, performance, and safety. One material that consistently stands out in the maritime industry is 5083 marine aluminum.

View Details5083 Marine Aluminum Round Bar for High Strength Offshore Reinforcements

In the demanding world of offshore engineering, materials must withstand severe environmental conditions without compromising structural integrity. One such pivotal material is the 5083 Marine Aluminum Round Bar.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details

Leave a Message