AntiCorrosion 5083 Aluminum Sheet for Marine

Marine environments expose materials to aggressive conditions such as seawater immersion, humidity, and salt spray, demanding superior corrosion resistance and mechanical performance. The 5083 aluminum alloy sheet is a top choice in the industry for fabricating vessels, offshore structures, and luxury yachts due to its outstanding anti-corrosive properties, excellent weldability, and good formability.

Alloy Classification

- Alloy Series: 5xxx Series (Aluminum-Magnesium)

- Primary Alloying Element: Magnesium (Mg), typically between 4.0-4.9%

- Secondary Elements: Manganese (Mn), Chromium (Cr), traces of Iron (Fe), Silicon (Si), Zinc (Zn), Copper (Cu)

The 5083 alloy is well-known for its superior resistance to seawater and industrial chemicals, making it suitable for high-strength marine applications.

Chemical Composition

| Element | Typical (%) | Standard Limits (%) |

|---|---|---|

| Aluminum (Al) | Balance | Remainder |

| Magnesium (Mg) | 4.0 - 4.9 | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 |

Mechanical Properties and Temper Conditions

AntiCorrosion 5083 aluminum sheets are typically supplied in the following temper designations, balancing strength and ductility for marine structural applications:

Working with 5083 aluminum sheet for marine applications, I've noticed a significant difference between theoretical corrosion resistance and real-world performance. While its inherent high strength and excellent corrosion resistance from the magnesium alloying are significant advantages, the devil is in the details. Surface preparation is paramount; even minor inconsistencies in cleaning or pre-treatment before painting or anodizing can lead to localized pitting or crevice corrosion, especially in the harsh marine environment. We've seen instances where seemingly minor scratches, overlooked during inspection, became nucleation points for significant corrosion over time, necessitating costly repairs or even replacement. Careful handling throughout the manufacturing process and stringent quality control are vital to maximizing the lifespan of the final product.

Furthermore, the interaction between 5083 aluminum and other metals is critical. Galvanic corrosion is a real threat if it's improperly coupled with dissimilar metals like steel or even other aluminum alloys. We've learned the hard way that even seemingly minor contact points, such as fasteners or welding spatter containing iron, can initiate significant galvanic corrosion if not properly addressed with insulation or appropriate sacrificial anodes. the specific marine environment – exposure to saltwater spray, immersion depth, and fouling organisms – is crucial for selecting appropriate protective coatings and maintenance strategies. Simply specifying "5083 aluminum" isn't enough; a comprehensive of the application and potential environmental factors is necessary to truly leverage its anti-corrosion properties.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| H111 | 275 - 305 | Min. 125 | Min. 12 | ~70 |

| H112 | 275 - 305 | Min. 145 | Min. 10 | 72 - 78 |

| H116 | 305 - 330 | Min. 185 | Min. 10 | 78 - 85 |

| H321 | 270 - 310 | Min. 145 | Min. 10 | 70 - 76 |

| O (Annealed) | 190 - 230 | 80 - 145 | 18 - 24 | 40 - 60 |

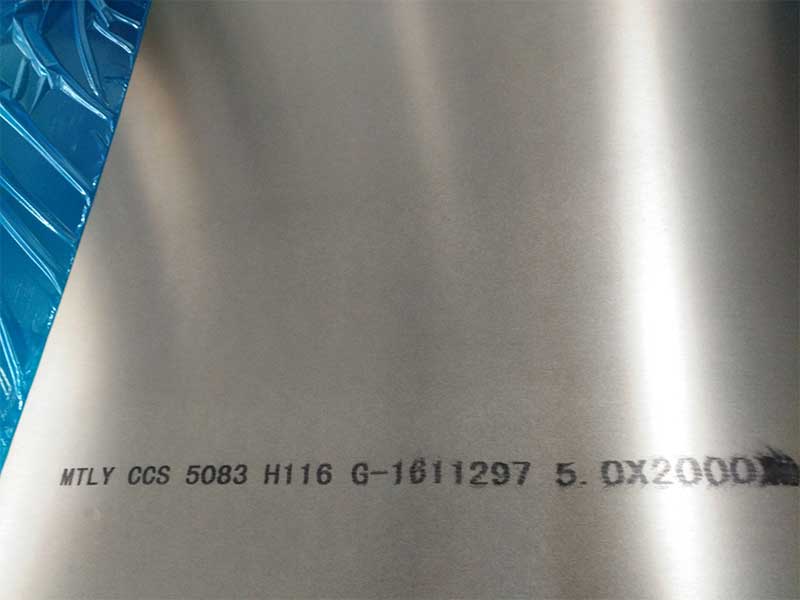

- H116 grade temper is commonly used in marine applications for its superior corrosion resistance and mechanical strength.

- H321 temper is often applied post-weld heat treatment to reduce residual stresses.

- O Temper achieves maximum ductility and softer structure used in forming processes.

Corrosion Resistance in Marine Environment

5083 alloy exhibits exceptional resistance to:

- Seawater and marine atmosphere

- Pitting and crevice corrosion resulting from saltwater exposure

- Stress corrosion cracking (SCC)

The high Magnesium content alongside controlled Mn and Cr addition contributes to enhanced oxide film formation and repassivation capabilities, which prevent localized corrosion typical of other aluminum alloy series.

Compared to traditional marine materials like carbon steel and stainless steel, 5083 aluminum eliminates the need for heavy coatings or maintenance-intensive cathodic protection systems while delivering higher strength-to-weight ratios.

Implementation Standards and Certifications

These aluminum sheets match and/or comply with the international industry standards ensuring quality, reliability, and interchangeability:

- ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN AW-5083 / EN 573-3 - European Standards for chemical composition and mechanical properties

- ISO 6361 - Rolled Aluminum Sheets - Grades and Quality

- MIL-DTL-46027 (US Military Spec) - Aluminum alloy sheet and plate for ship construction

- BS 1470 - Specification for aluminium alloy sheet and plate used in ship & boat building

Quality inspection testing includes ultrasonic defect detection, hydraulic flattening, tensile testing, and dimensional accuracy adherence.

Applications in Marine Industry

- Ship and boat hulls and superstructures

- Asymmetric load-bearing platform structures on offshore oil and gas rigs

- Parts for marine crating, container floors, and deck panels

- Equipment housings exposed to aggressive environments

- Unsheathed mobile bridges and shipyard fabrication outlets

Advantages of Choosing Our AntiCorrosion 5083 Aluminum Sheet

- Long-lasting natural corrosion resistance without additional coatings or plating

- Very high strength-to-weight ratio: critical for improving fuel efficiency and load capacities

- Excellent weldability (TIG, MIG, Spot welding) with minimal stress cracking risks

- High impact and abrasion resistance to withstand marine operations

- Minimal maintenance requirements throughout its lifecycle, reducing overall lifecycle costs

- Available in multiple temper grades and thickness ranges to meet specific application needs

Technical Specifications

| Parameter | Value |

|---|---|

| Thickness Range | 1.0mm - 150mm |

| Width Range | 500mm - 2500mm |

| Length | Customer specified, max continuous coils or split plates |

| Surface Finish | Mill finish, brushed or anodized option |

| Formability | Very high (O, H111 tempers) |

| Density | 2.66 g/cm³ (2650 kg/m³) |

| Thermal Conductivity | 121 W/m·K at 25°C |

| Melting Point | ~595°C |

Storage and Handling Recommendations

- Store sheets in a dry and well-ventilated area, avoiding direct floor contact

- Maintain packaging integrity before use to prevent surface contamination

- Handle with care to avoid dents or profile deformation during loading/unloading

Related Products

Marine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

Aluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View Details

Leave a Message