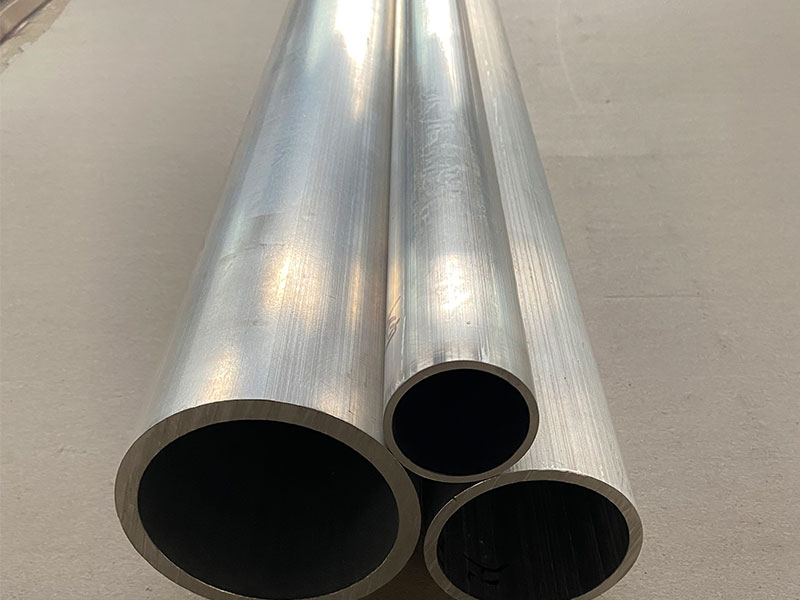

6082 Marine Aluminum Tubes for Saltwater Tolerant Marine Parts

6082 Marine Aluminum Tubes for Saltwater‑Tolerant Marine Parts

A structural engineer’s perspective on choosing the “workhorse” alloy for modern boats and offshore equipment

When designers talk about marine alloys for direct saltwater exposure, 6082 is often overshadowed by 5083 and 5754 plates. Yet for marine tubes and hollow sections bearing load—frames, masts, hydraulic lines, ladders, davits—6082 marine aluminum tubes quietly solve a problem that pure “corrosion-first” alloys usually can’t:

How do you maximize structural stiffness and machining precision in saltwater service without paying the weight or cost penalty of over‑engineering the section?

Viewed from this engineering standpoint, 6082 is not just “another 6xxx alloy.” It’s the high‑strength, heat‑treatable, extrusion‑friendly tube material that bridges two worlds:

- The corrosion-resistance heritage of 5xxx marine alloys

- The strength, machinability and T6/T6511 temper stability needed for accurate, highly loaded tube components

Below is a technically detailed, SEO-focused guide to 6082 marine aluminum tubes—aimed at naval architects, marine engineers and fabrication shops specifying tubes for saltwater‑tolerant marine parts.

Why 6082 for Marine Tubes? A Different Way to Frame the Choice

- Corrosion field:

Direct immersion, splash zones, crevice areas, dissimilar metal joints - Structural field:

Bending, torsion, vibration, impact, column buckling - Manufacturing field:

Extrusion, bending, welding, machining, surface finishing, availability

5083 scores very high in the corrosion field, but it’s harder to extrude into tight‑tolerance, complex tube shapes and is more difficult to machine cleanly. 6082, by contrast, sits at the optimum intersection for tubes:

- Strong enough to slim down wall thicknesses and reduce weight

- Corrosion‑resistant enough for above‑waterline and many submerged structural parts when properly protected

- Extrudable and machinable enough for precision marine tube components (hinges, steering components, valve bodies, high‑tolerance frames)

That is why serious builders use 5083 and 5086 heavily for plates and hulls—but deliberately choose 6082 for extruded marine tubes.

Typical Marine Applications of 6082 Aluminum Tubes

In saltwater environments, 6082 tubes are often specified for:

- Hull & superstructure frameworks

- Longitudinal frames, deck beams, T‑tops, rail systems

- Masts, booms & spars for sailing and workboats

- Railing, ladders & safety structures

- Stanchions, guard rails, pilot ladders, catwalk rails

- Offshore support structures

- Handrails, antenna mounts, equipment racks on rigs and platforms

- Hydraulic & pneumatic system housings

- Non‑pressure tube supports, guards, structural carriers, conduit

- Marine hardware & fittings

- Davits, dinghy cranes, swim step frames, folding platforms, bimini frames

- Transport & handling

- Rollers, tube beams for trailers, dock frames, gangway trusses

For continuously submerged and high‑risk crevice areas, sacrificial anodes, coatings or design modifications are usually applied with 6082, just as they are with other aluminum marine alloys.

6082 Marine Aluminum: Chemical Composition

The characteristic of 6082—as the “mc6061 with higher Mn and Si”—is best understood through its composition. It’s part of the Al‑Mg‑Si heat‑treatable family, but with higher manganese (Mn) for grain refinement and strength.

Typical Chemical Composition of 6082 Aluminum Alloy

(per EN 573‑3 / ISO 209, for extruded products)

| Element | % by Weight (Typical Range) |

|---|---|

| Silicon (Si) | 0.7 – 1.3 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | 0.4 – 1.0 |

| Magnesium (Mg) | 0.6 – 1.2 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Design insight:

- Mg + Si form Mg₂Si precipitates during heat treatment → high strength in T6/T651 conditions

- Mn improves toughness, controls grain size, slightly enhances corrosion resistance compared with 6061

This Triad (Al–Mg–Si + Mn) is why 6082 has become a go‑to marine tube alloy in Europe and globally.

Mechanical Properties & Parameters of 6082 Marine Aluminum Tubes

Mechanical performance varies by temper and product form (extruded tube vs plate). Tubes are typically extruded and then heat treated.

Common Tempers for Marine Aluminum Tubes in 6082

- 6082‑T5 / T52

Cooled from hot extrusion and artificially aged - 6082‑T6 / T6511 (most common for structural tubes)

Solution heat treated and artificially aged; T6511 is stress‑relieved by stretching, providing excellent dimensional stability for straight tubes - 6082‑O or T4

Used where high formability/bending is critical; strength is lower

Typical Mechanical Properties (Extruded 6082 Tubes)

Values are indicative; actual cert data may vary with dimension and supplier.

6082‑T6 / T6511 tube:

| Property | Typical Value* |

|---|---|

| Tensile Strength, Rm | 290 – 340 MPa |

| 0.2% Yield Strength, Rp0.2 | 240 – 280 MPa |

| Elongation (A5) | 8 – 12 % |

| Modulus of Elasticity (E) | ~70 GPa |

| Shear Strength (approx.) | ~190 MPa |

| Poisson’s Ratio | ~0.33 |

| Density | ~2.70 g/cm³ |

6082‑T5 tube:

| Property | Typical Value* |

|---|---|

| Tensile Strength, Rm | 260 – 310 MPa |

| Yield Strength, Rp0.2 | 200 – 260 MPa |

| Elongation (A5) | 8 – 12 % |

*Always design to certified MTC values and relevant standards.

Design perspective:

At a given diameter and wall thickness, a 6082‑T6 tube can carry significantly higher bending loads than a similar tube in softer 5xxx alloy. This permits:

- Thinner walls for weight savings, or

- Higher safety factors at constant weight

Marine Corrosion Resistance of 6082: Where It Excels and Where It Needs Help

For tubes in seawater, designers want to know: “Is 6082 as corrosion‑resistant as the 5xxx ‘marine’ plates?”

From a marine engineer’s perspective:

- 6082 offers good to very good corrosion resistance in natural seawater, particularly above the waterline and in spray zones.

- It is not as immune to certain forms of stress‑corrosion cracking and pitting as high‑magnesium 5xxx alloys (e.g., 5083) under continuous immersion.

Practical bottom line:

- Ideal for above‑waterline and intermittent splash structural tubes, railings, masts, frames, and offshore platform fittings.

- For permanent immersion in highly aggressive warm seawater, protective coatings, anodes and careful design against crevices are strongly recommended—this is equally true for many “marine” alloys.

Implementation Standards for 6082 Marine Aluminum Tubes

To ensure consistent performance, 6082 tubes for marine service should align with international standards covering chemical composition, mechanical properties, temper designation and dimensional tolerances.

Common Standards and Specifications

- EN 573‑3 – Chemical composition of 6082 aluminum alloy

- EN 755 series – Extruded rod, bar, tube and profiles

- EN 755‑1: Technical conditions for inspection and delivery

- EN 755‑2: Mechanical properties

- EN 755‑8: Seamless tubes

- EN 755‑9: Drawn tubes

- EN 485 / EN 515 – Temper designations and conditions

- ASTM B221 / ASTM B241 / ASTM B429 – Aluminum and aluminum-alloy extruded bars, rods, profiles, and tubes (incl. 6082 in many current documents)

- ISO 6362 – Wrought aluminum and aluminum alloy extruded rods/bars/tubes

Where marine class approvals are required (e.g., DNV, ABS, BV, LR), project-specific approvals can refer back to EN/ASTM material specifications but include additional requirements like fracture toughness, traceability, and weldability assessments.

Alloy Tempering for Marine Use: Choosing T5 vs T6 vs O

From the perspective of a tube fabricator, temper choice is where 6082’s flexibility really appears.

6082‑T6 / T6511 – For Maximum Strength and Straightness

- Solution heat-treated and artificially aged

- T6511 is further stress-relieved by stretching, reducing distortion during machining and service

- Best option where:

- Tubes carry high bending or compressive loads (e.g., mast sections, structural frames)

- Dimensional stability after machining is critical (e.g., fitting bodies, hydraulic housings, pinned joints)

6082‑T5 / T52 – Compromise Between Strength and Formability

- Air/water quenched from the extrusion temperature and then aged

- Slightly lower strength, slightly better ductility/bendability

- Popular for lightweight railings, ladders, boat frames that require field bending with mandrels.

6082‑O / T4 – When Extreme Formability Is Needed

- Fully annealed or naturally aged from solution-treated condition

- Lower strength but very high elongation

- Used for complex bent tube frames, then sometimes re‑heat‑treated post‑forming (by specialized suppliers)

fabrication insight:

For tight bends (small R/t) in marine tubes, many builders specify annealed sections, perform the bending, then apply a controlled artificial aging cycle. In that sense, suppliers who understand temper cycles as a design parameter (not just a label) can radically improve forming success rates and geometry accuracy.

Dimensional Parameters of 6082 Marine Aluminum Tubes

In marine systems, dimension control is just as critical as alloy choice. Examples of standard and custom tube parameters in 6082 include:

Common Dimensional Ranges

- Outside Diameter (OD): ~6 mm to 300+ mm

- Wall Thickness: ~0.5 mm to 25+ mm (project‑specific)

- Length: Standard 6 m or 12 m; custom cut‑to‑length services for shipyards and offshore yards

Tolerances (as per EN 755 / ASTM B221)

Typical tolerances, varying with size and precision level:

- OD tolerance: ±0.15–0.75 mm in common ranges

- Wall thickness tolerance: generally ±10%, tighter available for precision tubes

- Straightness: e.g., ≤1–1.5 mm per meter for standard structural tubes; stricter on request

- Ovality and concentricity: controlled in line with EN/ASTM charts, crucial for rotating or mating parts

Design trick:

For telescoping marine tubes (e.g., adjustable masts or ladders), using matched tolerance pairs within the 6082 extrusion system simplifies assembly and avoids galling or excessive play.

Welding & Joining Behavior in Marine Service

A question for marine engineers: “Can we weld 6082 tubes on the dock or in the yard without destroying performance?”

Weldability of 6082

- 6082 is considered readily weldable with MIG (GMAW) and TIG (GTAW) processes.

- Common filler alloys in marine applications:

- ER5356 (Al‑Mg) – Good strength, corrosion resistance, often preferred for seawater exposure

- ER4043 (Al‑Si) – Better fluidity, lower cracking risk, usually for less demanding marine locations

Impact of Welding on Properties

- The heat‑affected zone (HAZ) in 6082‑T6 can experience local strength reduction toward a T4‑like condition after welding.

- In design, treat welded zones conservatively with reduced allowable stresses (per EN / Eurocode / DNV rules).

- For highly critical welded marine structures, reinforcement or geometry optimization is wise (e.g., gusseting, avoiding high bending moments at weld locations).

Surface Treatment and Corrosion Protection in Saltwater

Alone, 6082 has respectable ambient seawater corrosion resistance. In executed marine designs, surface engineering can elevate its saltwater tolerance considerably.

Typical strategies:

- Mill finish + anodes

- Suitable for many above‑water structures in less aggressive conditions

- Anodizing (Type II or hard-anodizing for sliding/rotating parts)

- Increases corrosion resistance, adds wear resistance for telescopic tubes

- Dyeing optional for aesthetic/visual coding

- Marine‑grade powder coatings or epoxy paints

- For highly aggressive industrial / offshore atmospheres

- Applied over properly pre‑treated and sometimes anodized aluminum

- Galvanic isolation

- Crucial at joints with stainless or carbon steel

- Use insulating washers, sleeves, non‑conductive coatings

The synergy is what matters: 6062’s base alloy + an engineered surface system is often good enough even for harsh coastal and offshore locations, with service life measured in decades.

From a system‑level viewpoint, the question is never just “Is 6082 good?” but rather “For this tube application, is 6082 better than my other realistic choices?”

6082 vs 5083 / 5086 Tubes

- Strength: 6082‑T6 typically stronger in yield than as‑wrought 5xxx tube

- Formability: 5xxx is more forgiving for severe cold forming; 6082 needs suitable tempers

- Corrosion in full immersion: 5xxx alloys often better for long‑term bare immersion

- Machinability and extrusion complexity: 6082 usually wins for precise extrusions and clean machining

Use 6082 when the tube is high‑precision or highly loaded and corrosion can be managed by design and surface protection.

6082 vs 6061 Tubes

6092 is often considered the “Euro‑centric” alternative to 6061 with:

- Slightly higher strength in many conditions

- Better grain refinement and ductility due to Mn

- Similar welding and machining behavior

If you design globally, think of 6082 as the higher‑performance, EN‑driven cousin to 6061 for structural marine tubes.

Design & Specification Checklist for 6082 Marine Aluminum Tubes

When specifying 6082 marine aluminum tubes for saltwater‑tolerant parts, a robust engineering specification might cover:

- Alloy & temper:

- Example: EN AW‑6082 T6511, seamless extruded tube, marine application

- Dimensional details:

- OD, wall thickness, length, straightness class, ovality

- Standards & inspection:

- Conformance to EN 573‑3, EN 755‑8 or ASTM B241 (as relevant)

- Require specific EN 755‑2 mechanical property classes

- Mill test certificates (MTC) including chemical & mechanical data

- Surface condition:

- Mill finish / anodized / coated, Ra requirements for sealing surfaces

- Welding and fabrication:

- Approved filler alloys, preheating temperature limits, post‑weld inspection criteria

- Corrosion strategy:

- Coating system, anode strategy, galvanic isolation details

Treating tubes as critical structural components with a full “design envelope” (not just a commodity part) greatly reduces lifecycle risk in marine projects.

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Tubes for Saltwater Tolerant Marine Parts

6082 Marine Aluminum Tubes for Saltwater‑Tolerant Marine PartsA structural engineer’s perspective on choosing the “workhorse” alloy for modern boats and offshore equipmentWhen designers talk about marine alloys for direct saltwater exposure, 6082.

View Details6082 Marine Aluminum Tubes for Coastal Marine Infrastructure

In native natural ecosystems straddling our planet’s coastlines, coastal marine infrastructure serves as the lifeblood of myriad industries, ranging from transportation to tourism, aquaculture, and conservation initiatives.

View Details

Leave a Message