5083 Marine Aluminum I Beams for Saltwater Proof Shipbuilding

In the realm of modern shipbuilding, especially vessels operating in saline environments, the choice of structural materials dramatically influences durability, safety, and overall performance. 5083 Marine Aluminum I Beams have emerged as a preferred solution, offering exceptional strength, corrosion resistance, and longevity that traditional materials often lack.

The 5083 aluminum alloy is one of the most popular marine-grade aluminum alloys due to its remarkable resistance to seawater corrosion without post-weld heat treatment. It is predominantly used in the shipbuilding, oil and gas platforms, and railcar industries. Its balanced properties optimize weight reduction while maintaining structural integrity, making it excellent for marine I beams.

Core Functions of 5083 Marine Aluminum I Beams

- Structural Rigidity: I beams offer high bending resistance with an excellent strength-to-weight ratio. In ships, they support decks, bulkheads, and hull frameworks.

- Corrosion Resistance: 5083 alloy's magnesium content ensures an outstanding defense against saltwater corrosion, extending the lifespan of the beam.

- Lightweight: Less weight means higher fuel efficiency and ease in handling during construction.

- Weldability: 5083 aluminum welds well, retaining strength along welded joints necessary for shipbuilding.

- Durability: Capable of withstanding large fluctuations in temperature and marine environments without approaching cracking thresholds.

Applications in Saltwater Proof Shipbuilding

5083 marine aluminum I beams are foundational in many areas, including:

- Ship Deck Girder Systems: Supporting decks with rigidity while assisting in load distribution.

- Hull Structures: Reinforcing hull strength and absorbing impact stress effectively.

- Bulkheads and Frames: Forming compartmental barriers and ship frame structures that resist salt corrosion.

- Marine Platforms and Offshore Builds: Installed in floating docks and water-based structural supports that resist marine wear.

- Ferry and Commercial Vessel Beds: Due to lightweight and high corrosion protection, they save operational costs over steel alternatives.

Technical Specifications and Standards

| Property | Value | Standard / Test Method |

|---|---|---|

| Alloy Designation | 5083 | ASTM B209, ISO 6361 |

| Temper | H116 / H321 | MIL-DTL-46027 |

| Density | 2.66 g/cm³ | ASTM B549 |

| Yield Strength | 215 MPa (H116) | ASTM E8 |

| Tensile Strength | 295 MPa (H116) | ASTM E8 |

| Elongation | 12% | ASTM E8 |

| Fatigue Strength | 138 MPa | DNVGL-RP-C203 |

| Thermal Conductivity | 130 W/m·K | ASTM E1952 |

| Melting Point | 570°C - 640°C | |

| Corrosion Resistance | Excellent in seawater | ISO 9227 - Salt Spray Test |

Implementation Standards

5083 marine aluminum I beams conform to major maritime and industry optimal practices such as:

- ISO 9001 Quality Management

- ASTM International material certification

- DNV GL, ABS, and Lloyd's Register standards for marine materials

- MIL-DTL-46027 for plating compatibility

- Relevant ROHS directives for environmental safety compliance

Chemical Composition of 5083 Alloy

A clear of the alloy's elements clarifies its corrosion and mechanical property balance. Below is the typical chemical composition in mass percent (%):

| Element | Composition Range |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

The relatively high magnesium in the alloy is critical to improving corrosion resistance in ocean environments while maintaining mechanical strength.

Tempering Conditions Explained

Temper condition significantly affects the mechanical properties and service performance of 5083 marine aluminum I beams. The alloys are supplied typically as:

| Temper | Description | Application |

|---|---|---|

| H116 | Strain-hardened, stabilized for offshore use | Standard marine grade; excellent saltwater resistance |

| H321 | Solution heat-treated and strain-hardened | Applied for improved workability and strength retention |

| O | Annealed (soft) | Lower mechanical properties, easier fabrication stages |

Among these, H116 is most common for shipbuilding due to its balance of corrosion resistance and strength without the need for heat treatment after welding.

| Property | 5083-H116 Marine Aluminum |

|---|---|

| Density | 2.66 g/cm³ |

| Ultimate Tensile Strength | 295 MPa |

| Yield Strength | 215 MPa |

| Elongation at Break | 12% |

| Hardness (Brinell) | 75 HB |

| Modulus of Elasticity | 70 GPa |

| Fatigue Strength | 138 MPa (at 5x10⁶ cycles) |

| Corrosion Resistance | Excellent in marine environment |

Advantages Over Traditional Steel

| Feature | 5083 Marine Aluminum | Conventional Marine Steel |

|---|---|---|

| Weight | ~1/3 of steel | Heavy |

| Corrosion Resistance | High, naturally forms oxide layer | Requires protective coatings |

| Maintenance | Minimal to moderate | Frequent painting and repair |

| Weldability | Excellent | Good but susceptible to rust |

| Durability | High in seawater environments | Moderate without frequent treatment |

| Thermal Conductivity | Higher – assists in cooling | Lower |

Final Thoughts

5083 marine aluminum I beams represent a state-of-the-art solution for the saltwater proof shipbuilding industry. Combining light weight, exceptional corrosion resistance, and mechanical properties make it highly suited for a wide variety of marine applications from hull frameworks to offshore platform structural support.

For naval architects, boat-building companies, and marine equipment specialists aiming to enhance lifecycle performance with reduced maintenance costs, investing in 5083 marine aluminum I beams offers tangible benefits aligned with international standards and proven durability in saltwater environments.

Choosing the right aluminum marine I beam is more than just engineering - it's about protecting vital infrastructure and ensuring sustainable marine operations for decades to come.

Related Products

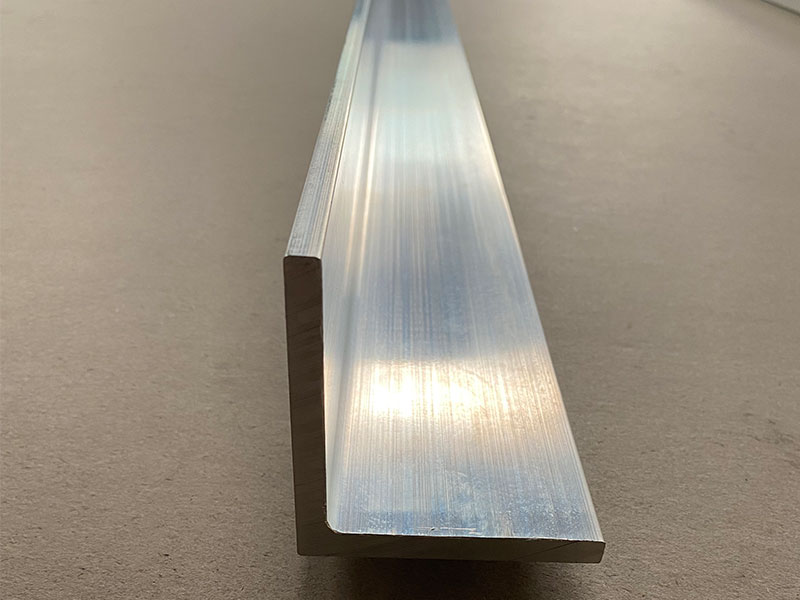

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

5083 Marine Aluminum Flat Bar for Saltwater Proof Shipbuilding Parts

5083 Marine Aluminum Flat Bar for Saltwater Proof Shipbuilding PartsSaltwater is an unforgiving engineer. It creeps into seams, concentrates in crevices, accelerates galvanic attack, and punishes anything that relies on coatings alone.

View Details5083 Marine Aluminum Flat Bar for Offshore Platform Design

5083 marine aluminum flat bar delivers high strength, outstanding corrosion resistance, and excellent weldability, making it a preferred material choice for offshore platform design, topside structures, walkways, brackets.

View Details5083 Marine Aluminum Channels for Offshore Platform Construction

In the demanding world of offshore platform construction, material selection forms the backbone of structural integrity, durability, and performance. With increasing emphasis on lightweight and corrosion-resistant materials.

View Details5083 Marine Aluminum Angles for Custom Offshore Vessel Reinforcement

Aluminum alloy 5083 marine aluminum angles are a premium-grade aluminum product specifically engineered for demanding marine and offshore environments. Renowned for excellent corrosion resistance, superior strength, and excellent weldability.

View Details5083 Marine Aluminum Channels for Lightweight Boat Deck Design

The marine industry continually seeks efficiency and versatility in boat construction. Among the materials available, 5083 marine aluminum channels have emerged as a stellar choice for lightweight boat deck design.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details

Leave a Message