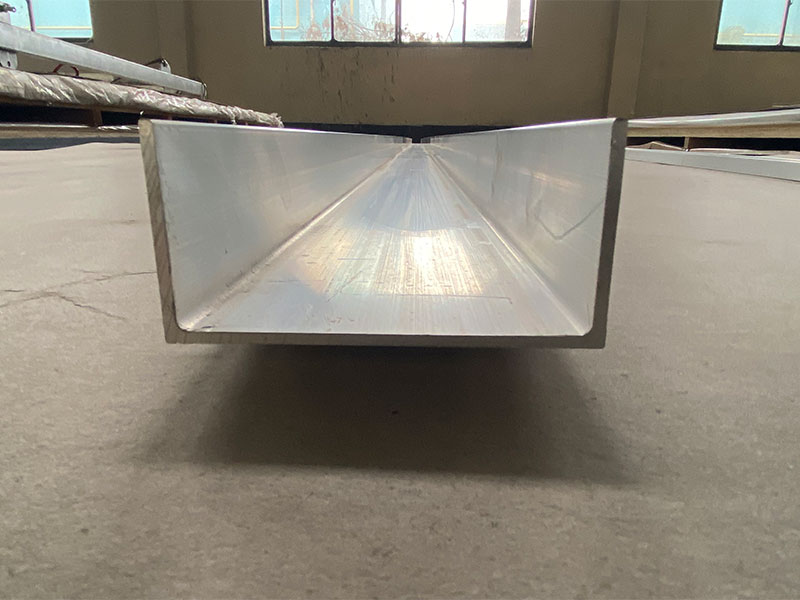

5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment, this alloy is an industry benchmark for marine and saltwater exposure projects.

Chemical Composition (% by weight)

| Element | Min | Max |

|---|---|---|

| Aluminum (Al) | Balance | - |

| Magnesium (Mg) | 4.0 | 4.9 |

| Manganese (Mn) | 0.4 | 1.0 |

| Chromium (Cr) | 0.05 | 0.25 |

| Iron (Fe) | - | 0.4 |

| Silicon (Si) | - | 0.4 |

| Copper (Cu) | - | 0.1 |

| Zinc (Zn) | - | 0.25 |

Mechanical Properties of 5083 Alloy I Beams

| Property | Value |

|---|---|

| Density | 2.66 g/cm³ |

| Tensile Strength | 275 - 340 MPa |

| Yield Strength (0.2% offset) | 125 - 215 MPa |

| Elongation at Break | 12 – 16 % |

| Modulus of Elasticity | ~70 GPa |

| Hardness (Brinell) | 70 - 90 HB |

Features of 5083 Marine Aluminum I Beams

1. Superior Corrosion Resistance

- Due to the high magnesium content and added chromium, 5083 aluminum provides exceptional resistance against seawater, industrial chemicals, and marine atmospheres. This significantly reduces maintenance and replacement costs.

2. High Strength-to-Weight Ratio

- These I beams exhibit excellent tensile and yield strength, supporting heavy structural loads typical in dock, seawall, and offshore platform construction without excessive weight.

3. Enhanced Weldability

- The 5083 alloy’s ability to be easily welded using conventional techniques ensures flexible fabrications, repair work, and precise assembly in complex coastal structures.

4. Excellent Fatigue Resistance

- Coastal structures are prone to repeated wave and current impacts. 5083 aluminum’s fatigue strength helps extend the operational life of marine structures under cyclic loading.

5. Dimensional Stability & Formability

- With good workability, these beams can be custom-extruded or fabricated into specific I cross-sections tailored to diverse engineering specifications.

Applications in Coastal Engineering

1. Marine and Offshore Structures

5083 I Beams are extensively used in constructing piers, jetties, offshore platforms, floating docks, and shipbuilding frameworks. The alloy withstands saltwater corrosion and mechanical stress from continuous marine conditions.

2. Seawalls & Coastal Defenses

The beams serve as integrally supporting members in seawalls, breakwaters, and groynes to resist tidal erosion, wave action, and storm surges while maintaining structural integrity over long periods.

3. Harbors and Ports Infrastructure

Facilities such as whale guards, quay walls, ramp systems, and crane support structures utilize 5083 beams for strength with corrosion loyalty, ensuring steady operational confidence against harsh coastal weathering.

4. Bridge and Walkways Near Saline Environments

5083 aluminum beams support coastal pedestrian bridges, boardwalks, and marina walkways, providing a rust-free, maintenance-light solution.

5. Water Treatment and Offshore Energy Facilities

Corrosion-resistant properties suit applications within desalination plants, tidal power installations, wind turbine foundations, and offshore oil/gas rigs.

Dimensional Specifications and Availability

5083 aluminum I beams are available in multiple sizes to meet specific load-bearing and span requirements with options customized to project marks. Typical flange widths can vary from 50mm to 300mm; web depths from 75mm to 500mm with thickness options from 5mm upwards.

Note: Consult with our engineering team to determine optimal beam profiles and sizes tailored for your particular environmental load criteria.

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5083 Marine Aluminum Channels for Lightweight Marine Vessel Design

5083 Marine Aluminum Channels for Lightweight Marine Vessel Design: A Perfect Fusion of Strength, Durability, and Corrosion ResistanceIn the evolving world of marine vessel design, the quest for materials that offer unbeatable strength.

View Details5083 Marine Aluminum Z Shaped Sections for Offshore Vessel Frame Design

In the demanding offshore marine environment, the structural integrity and corrosion resistance of vessels are crucial for reliable performance and safety.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details

Leave a Message