5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance. Among the available choices, 5083 Marine Aluminum Tubes is know as a top-grade material specifically engineered to meet the challenges posed by saltwater exposure, heavy usage, and structural demands in boat building.

5083 aluminum is a part of the 5xxx series aluminum-magnesium alloys, well-regarded for their excellent corrosion resistance, high strength, and good weldability. The 5083 alloy possesses superior properties making it an ideal candidate for marine and structural applications where high resistance to seawater corrosion is critical.

Chemical Composition of 5083 Aluminum Alloy (Typical Values)

| Element | Composition Range (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties of 5083 Aluminum Tubes

| Property | Typical Value |

|---|---|

| Ultimate Tensile Strength (150 mm/min) | 28,000 – 35,000 psi (190-230 MPa) |

| Yield Strength (0.2% offset) | 22,500 – 28,000 psi (155-195 MPa) |

| Elongation (%) | 10 – 17% |

| Brinell Hardness (HB) | 75 – 90 |

| Density | 2.66 g/cm³ |

Features of 5083 Marine Aluminum Tubes

1. Outstanding Corrosion Resistance

5083 aluminum alloy tubes are excellent in resisting corrosion—especially marine environments such as saltwater and brackish water—thanks to higher magnesium content and minor chromium and manganese additions that improve oxidation resistance and combat pitting corrosion.

2. High Strength-to-Weight Ratio

While 5083 offers high strength, it remains lightweight compared to steel tubes, improving overall vessel efficiency and providing fuel savings while maintaining structural integrity, especially important in marine transport.

3. Superb Weldability

One primary advantage of 5083 tubes is excellent weldability enabling precise and solid boat fabrication and complex hull and superstructure designs without compromising structural strength, commonly concealed by marine finishes.

4. Excellent Workability

5083 tubes afford good formability allowing bending and shaping necessary for custom boat building needs without much risk of cracking or weakening.

5. Longevity and Reliability

Due to its engineering and material advantages, 5083 tubes significantly extend vessel life while requiring minimal maintenance. The reliability reduces downtime and increases safety for commercial or recreational marine applications.

Typical Applications in Boat Building and Fabrication

| Application | Description |

|---|---|

| Hull Construction | Structural tubes forming the vessel backbone for lightweight strength and corrosion resistance. |

| Deck Support and Framing | Precise framing and support structures that withstand sea stresses and dynamic loads. |

| Marine Piping and Framework | Tubular structural frameworks for fittings, hydraulics, and ventilation systems exposed to marine environments. |

| Boat Trailers and Racks | Corrosion-resistant support for transporting vessels, maintaining longevity despite environmental exposure. |

| Superstructure Fabrication | Tubing or extrusion shapes used in fabricating decks, railings, and battens that require a fused lightweight metal. |

| Watertight Compartments | Formation of rigid, highly corrosion-resistant enclosed duct work in sophisticated flotation and pumping systems. |

Comparison with Other Marine Materials

| Material | Corrosion Resistance | Strength-to-Weight | Weldability | Cost-effectiveness | Maintenance |

|---|---|---|---|---|---|

| 5083 Aluminum Alloy | Excellent | High | Excellent | Moderate | Low |

| Stainless Steel | Good | Medium | Moderate | High | Medium |

| Carbon Steel | Poor (rusts) | Very High | Good | Low | High |

| Fiberglass | Good (non-metallic) | Medium | Specialized | Moderate | Medium |

Quality Standards and Availability

Our 5083 marine aluminum tubes are manufactured according to industry standards including:

Working with 5083 marine aluminum tubes for boat building presents a unique set of challenges and advantages. Its high strength-to-weight ratio is a major selling point, allowing for lighter, more fuel-efficient vessels. However, the material's inherent work-hardening characteristic demands careful consideration during fabrication. We've found that improper bending techniques, particularly on larger diameter tubes, can lead to cracking or weakening in the material, requiring meticulous planning and potentially specialized tooling. Furthermore, achieving consistent, high-quality welds is crucial, especially in areas subject to high stress like the hull or transom. Our team has invested heavily in training on appropriate welding techniques, including pulse welding and specialized filler materials, to mitigate issues like porosity and ensure optimal weld integrity.

Beyond fabrication, the longevity of 5083 aluminum tubes is directly impacted by surface preparation and protective coatings. We've seen instances where inadequate cleaning prior to painting or anodizing led to premature corrosion, especially in saltwater environments. Therefore, a rigorous pre-treatment process, including thorough degreasing and chemical etching, is essential before applying any protective layer. Furthermore, the choice of coating itself is critical; we've found that certain epoxy-based coatings offer superior protection against marine fouling and corrosion compared to others, significantly extending the lifespan of the finished product and minimizing potential warranty claims down the line. these nuances is to producing reliable and long-lasting boats

- ASTM B637 / B241 – Specifications for seamless and welded aluminum tubes for marine applications.

- ISO 6361 – Wrought aluminum and aluminum alloy sheets, strips, and plates.

- ABS and DNV regulations – Certification in some cooperations consistent with marine classification societies for vessel safety compliance.

They are available in various outer diameters (OD), wall thicknesses, and lengths to meet the customized requirements of your boat-building project.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

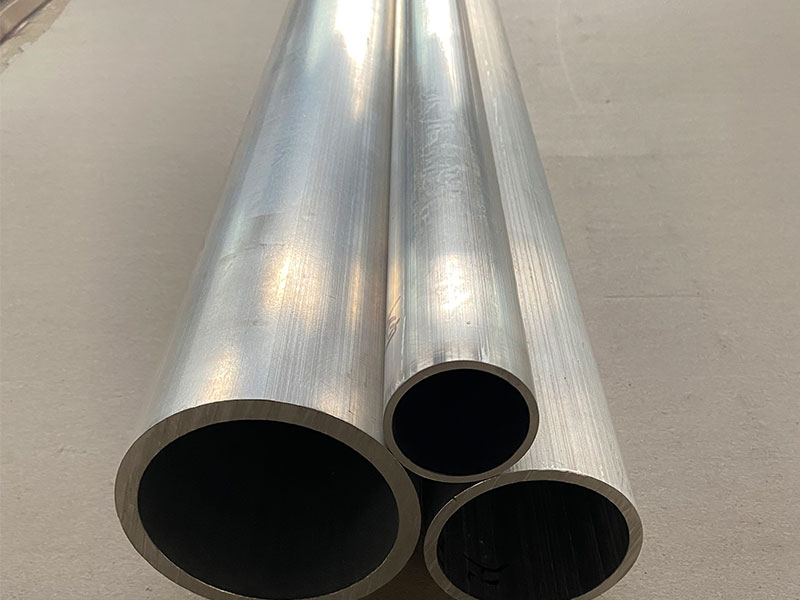

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

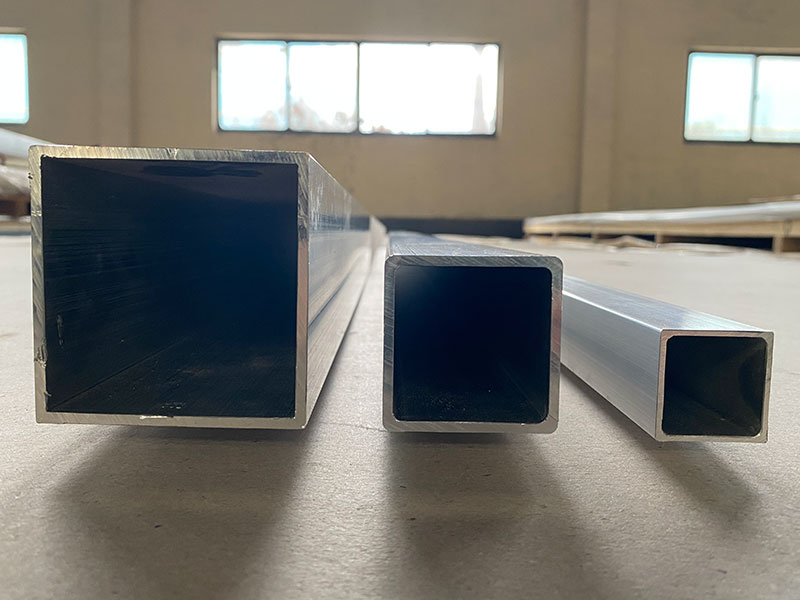

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details

Leave a Message