5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment. 5083 marine aluminum tubes have emerged as an outstanding choice in shipbuilding due to their exceptional mechanical properties, corrosion resistance, and lightweight characteristics.

5083 is an aluminum-magnesium alloy renowned for its superior strength, excellent corrosion resistance, and good weldability. It is widely used in marine applications where exposure to sea water and harsh environmental conditions demand materials that maintain integrity without excessive maintenance.

| Alloy | Chemical Composition (%) | Features |

|---|---|---|

| Aluminum | Bal | Base metal |

| Magnesium | 4.0 – 4.9 | Enhances strength and corrosion resistance |

| Manganese | 0.4 – 1.0 | Improves mechanical properties |

| Iron | 0.4 max | Minimizes embrittlement |

| Silicon | 0.4 max | Controls casting characteristics |

| Copper | 0.1 max | Limits reduces stress-corrosion cracking |

| Zinc | 0.25 max | Maintains overall alloy performance |

Mechanical Properties of 5083 Aluminum Tubes

| Property | Typical Value | Testing Standard |

|---|---|---|

| Density | 2.66 g/cm³ | ASTM B209 |

| Tensile Strength (Ultimate) | 290 – 350 MPa | ASTM E8 / ISO 6892 |

| Yield Strength | 145 – 215 MPa | ASTM E8 / ISO 6892 |

| Elongation at Break | ≥ 12 % | ASTM E8 / ISO 6892 |

| Hardness (Brinell) | 65 – 90 HB | ASTM E10 |

| Thermal Conductivity | 121 W/m·K | ASTM E1952 |

These properties make 5083 tubes ideal for structural reinforcement where high tensile strength and toughness are required without sacrificing weight.

Features of 5083 Marine Aluminum Tubes

Superior Corrosion Resistance:The high magnesium content provides excellent resistance to seawater corrosion, especially in hull structures continuously exposed to saline environments.

High Strength-to-Weight Ratio:Despite their lightweight, 5083 tubes offer robust mechanical strength ideal for reinforcing ship hulls while reducing overall vessel weight to improve fuel efficiency.

Exceptional Weldability:Suitable for MIG, TIG, and resistance welding processes, facilitating easy fabrication and repair during ship construction or maintenance.

Good Formability:5083 tubes can be extruded into complex shapes and curves required in hull design.

Enhanced Impact and Fatigue Resistance:Resin-infused hulls experience dynamic loads; 5083 tubes help sustain structural integrity under repeated stress and impact conditions.

Non-Magnetic:Minimizes issues in vessels requiring low magnetic signature such as naval ships.

Applications of 5083 Aluminum Tubes in Ship Hull Construction

1. Ship Hull Structural Reinforcement

5083 tubes provide additional strength to longitudinal and transverse framing systems within hulls, reinforcing areas subjected to high stress from ocean waves and cargo loads.

2. Bulkheads and Deck Support Tubing

Its lightweight yet strong characteristics are perfect for internal deck structures that require load-bearing capability and corrosion performance over decades at sea.

3. Piping and Integral Tubing

Used extensively for piping in cooling, fuel, or hydraulic systems embedded within hull assemblies that require corrosion resistance against seawater exposure and salt spray.

4. Superstructure Elements

Applications extend beyond hull bottoms, 5083 tubes are also frequently adopted in constructing ship superstructures and topside frames due to strength and low weight.

5. Offshore Platforms and Floating Structures

Increasingly utilized in marine offshore infrastructure, providing toughness and resistance against vertically and horizontally applied forces in hostile platforms.

Related Products

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

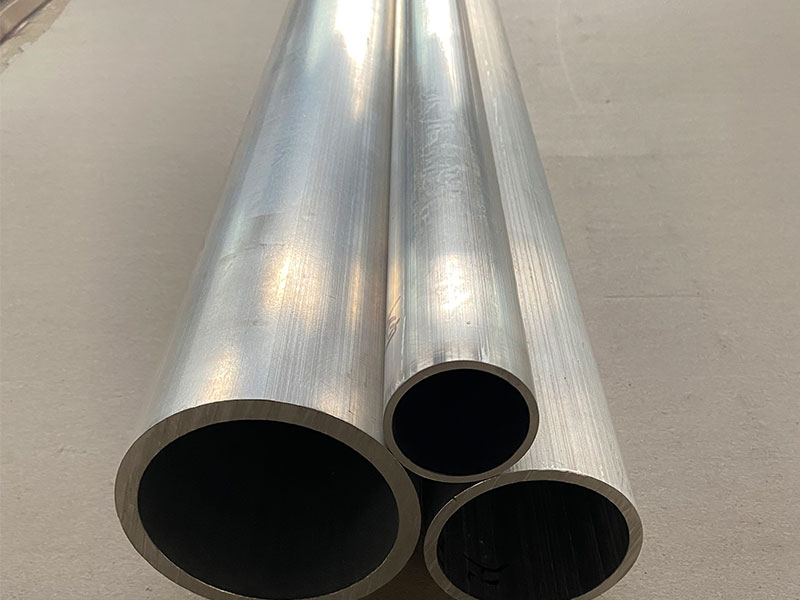

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

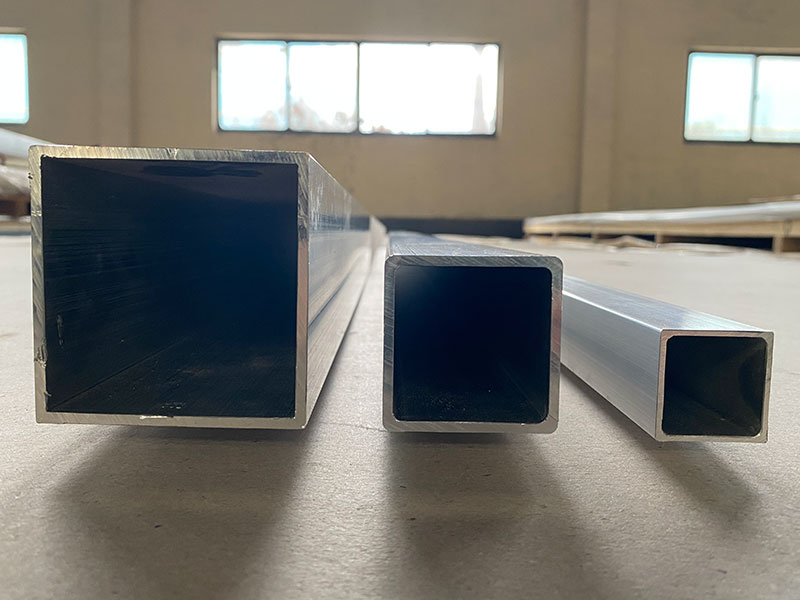

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details

Leave a Message