5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution, renowned for their unique properties and versatile applications in boat construction and coastal engineering.

Why 5083 Marine Aluminum Tubes?

Marine environments challenge materials with continuous exposure to saltwater, varying temperatures, and mechanical stresses. The 5083 alloy, an aluminum-magnesium manganese metallurgical blend, stands out for its remarkable corrosion resistance, high strength-to-weight ratio, and excellent weldability. These tubes not only provide structural integrity but also ensure longevity and safety in coastal applications.

Working with 5083 marine aluminum tubes in coastal boat engineering presents a unique set of challenges and opportunities. The excellent corrosion resistance of 5083, particularly in saltwater environments, is paramount. However, we've found that proper surface preparation is critical before welding or coating. Insufficient cleaning can lead to pitting and compromised weld integrity, significantly shortening the lifespan of the tube structure. Furthermore, the inherent work-hardening of 5083 requires careful consideration during bending and forming processes; excessive stress can lead to cracking, especially in complex geometries. We’ve experimented with different annealing techniques to optimize formability without sacrificing strength, leading to improved efficiency in our production line and resulting in a more robust final product.

Beyond material properties, the specific coastal environment is key. The constant exposure to salt spray, UV radiation, and fluctuating temperatures necessitates a holistic approach to design. We've seen instances where seemingly minor design flaws, such as inadequate drainage or improperly sealed joints, lead to accelerated corrosion. Therefore, we emphasize meticulous design and fabrication practices, including the use of compatible sealants and coatings to maximize the longevity and structural integrity of the 5083 tubes in the demanding coastal marine environment. Careful consideration of factors like crevice corrosion and galvanic reactions with other metals used in the boat construction is also essential for a successful outcome.

Functions and Applications

1. Structural Framework and Hull Construction5083 marine aluminum tubes serve as the backbone in constructing the structural framework of coastal boats and small to medium-sized vessels. Their high tensile strength (290 MPa to 350 MPa depending on tempering) supports essential mechanical loads, ensuring hull rigidity and resistance to bending or buckling under harsh maritime conditions.

2. Hydraulic and Fuel Line SystemsDue to their corrosion resistance, these tubes are ideal for fluid conveyance systems onboard maritime vessels. Whether used to channel hydraulic fluids or fuel, 5083 aluminum tubes consistently resist pitting and stress corrosion cracking—a common issue in saltwater exposure.

3. Offshore Platforms and Dock ComponentsBeyond boatbuilding, 5083 tubes are implemented in building offshore platform structures and coastal dock frames where mechanical resilience and durability against chloride ions in seawater are mandatory. Their lightweight yet robust nature allows for easier installation and better design flexibility.

Technical Parameters

| Parameter | Specification |

|---|---|

| Alloy | 5083 Marine Grade Aluminum Alloy |

| Temper | O, H111, H116 (Common Marine Tempers) |

| Density | 2.66 g/cm³ |

| Tensile Strength | 290–350 MPa |

| Yield Strength | 145–215 MPa |

| Elongation at Break | 12–20% |

| Corrosion Resistance | Excellent, especially in saltwater |

| Weldability | Outstanding |

| Typical Dimensions | Diameter: 10 mm – 150 mm; Wall Thickness: 1 mm – 10 mm |

| Surface Finish | Mill finish, anodized, or coated per application needs |

Alloy Tempering and Production Conditions

The choice of tempering significantly influences the mechanical properties of 5083 aluminum tubes. The O temper refers to annealed states offering maximum ductility but lowered strength, preferred for shaped formability during manufacturing. H111 temper involves a strain-hardened stage with some reduction in ductility for enhanced strength suitable for structural elements. H116 temper is widely applied in marine-grade alloys subjected to welding processes since it combines both corrosion resistance and corrosion fatigue strength after welding.

Production of marine-grade 5083 tubes usually adheres to stringent standards such as ASTM B221 and ISO 6361-1, ensuring consistency in chemical composition, mechanical performance, and dimensional accuracy.

Detailed Chemical Composition

| Element | Composition Range (wt.%) |

|---|---|

| Aluminum (Al) | Balance (typically ~94.6–96.5%) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Chromium (Cr) | 0.05 – 0.25 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.05 each |

The elevated magnesium content is principally responsible for improved strength and corrosion resistance, whereas Mn contributes to the material’s hardness and weldability.

The Distinctive Edge in Coastal Engineering

From our articulative perspective, 5083 aluminum tubes are more than just metallic conduits; they embody a material synergy tailored to confront marine forces with exceptional resilience and functional versatility. Implementing these tubes within coastal boat manufacturing integrates structural ingenuity with corrosion science, facilitating vessels with superior longevity and robustness that outperform many traditional materials.

Engineers leveraging 5083 marine aluminum invest not only in optimal strength-to-weight capability but also in long-term maintenance feasibility as these tubes reduce upkeep costs and exposure risks when deployed in severe saline conditions. Their ductility variations offer adaptable solutions tailored to specific manufacturing steps—from shaping in softer tempers to final structural reinforcement with tempered alloys.

Related Products

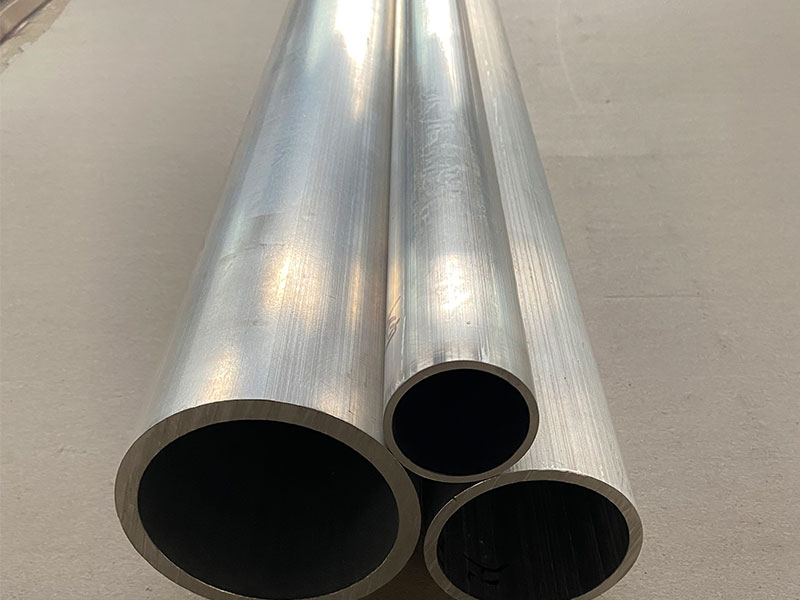

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

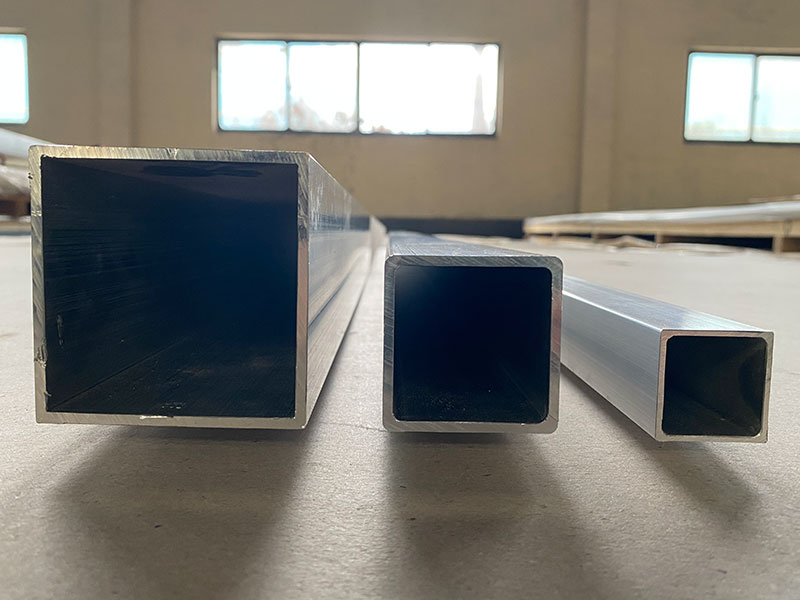

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details

Leave a Message