5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice, particularly for fabricators and engineers focusing on commercial marine vessels.

Why 5083 Aluminum Tubes Excel in Marine Applications

5083 is an aluminum-magnesium alloy famed for its extraordinary strength and excellent corrosion resistance, especially in saltwater environments. This blend of properties ensures that 5083 marine aluminum tubes endure harsh oceanic conditions, extending the service life of commercial marine parts such as hull frameworks, pipelines, structural supports, and exhaust systems.

Compared to steel and other aluminum alloys like 6061, 5083 provides:

- Superior resistance to seawater corrosion and pitting

- Outstanding tensile strength retention after welding

- Easy weldability with less susceptibility to stress cracking

- A balance of lightweight and mechanical integrity critical in marine design

Chemical Composition of 5083 Marine Aluminum Tubes

the chemical makeup helps naval architects appreciate why 5083 alloys endure marine environments better than many alternatives.

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (~94.82-96.32) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.4 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.05 bottleneck each |

This elevated magnesium content boosts solid-solution strengthening and confers enhanced resistance against galvanic corrosion that maritime parts frequently encounter.

Standard Implementation and Manufacturing Criteria

The manufacturing and testing of 5083 marine aluminum tubes must comply with international standards devised specifically for marine alloys, such as:

- ISO 11960: Defines seamless and welded steel or aluminum alloy tubes for seawater and brackish water services aboard ships.

- ABS (American Bureau of Shipping) and DNV-GL Certification: Ensures the tubes meet marine classification societies’ durability, welding, and mechanical behavior.

- ASTM B209 & B221: General aluminum alloy plate and extruded product standards refer to 5083 alloy on various shaping and quality requisites.

Aligning with these ensures finished marine parts not only fit dimensional and mechanical norms but maintain structural integrity even after exposure to textured marine operational stresses.

Tempering Conditions: Temper Variants for Real-World Performance

Typically, 5083 aluminum tubing is provided in tempers ranging from O (annealed), H111 (strain-hardened), to H321 (strain-hardened & stabilized through low-temperature heat).

- O Temper (Annealed): Softest state, offering best formability and ease for bending or forming parts but with lower strength.

- H111 Temper: Slightly stronger, usually employed for structural marine parts needing moderate work hardening, excellent for rotated bending or corrosion-resistant pipelines.

- H321 Temper: Suitable for parts subjected to higher stress and greater durability requirements, heat stabilized to prevent strength loss over time.

Matching the temper with part function is essential for optimizing tube performance, particularly Helicopter deckrails, piping conduits, or engine cooling tubes that undergo cyclic fatigue and multibending jobs.

Mechanical Parameters of 5083 Marine Aluminum Tubes

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength (Ultimate) | 275 – 350 MPa |

| Yield Strength | 125 – 215 MPa |

| Elongation (%) | 12% – 20% |

| Hardness (Brinell) | ~60 to 75 HB |

| Modulus of Elasticity | 69 GPa |

| Density | 2.66 g/cm³ |

These parameters balance toughness and fatigue resistance—a must-have for building ergonomic and safe commercial marine structures with aluminum tubes.

Applications in Commercial Marine Solutions

Given their dimensional stability and low weight, 5083 marine aluminum tubes are the backbone of many commercial vessels globally. Specific usages include:

- Pipework for seawater systems: corrosion-resistance ensuring resistance to saltwater abrasion.

- Structural components: rails, supports, and framework maintaining mechanical performance under load.

- Hydraulic and fuel lines: resistance against chemical and weather degradation preserves piping integrity.

Substituting steel for these aluminum alloys results in lighter vessels that consume less fuel, meet stringent classification requirements, and require less maintenance during prolonged deployments.

Related Products

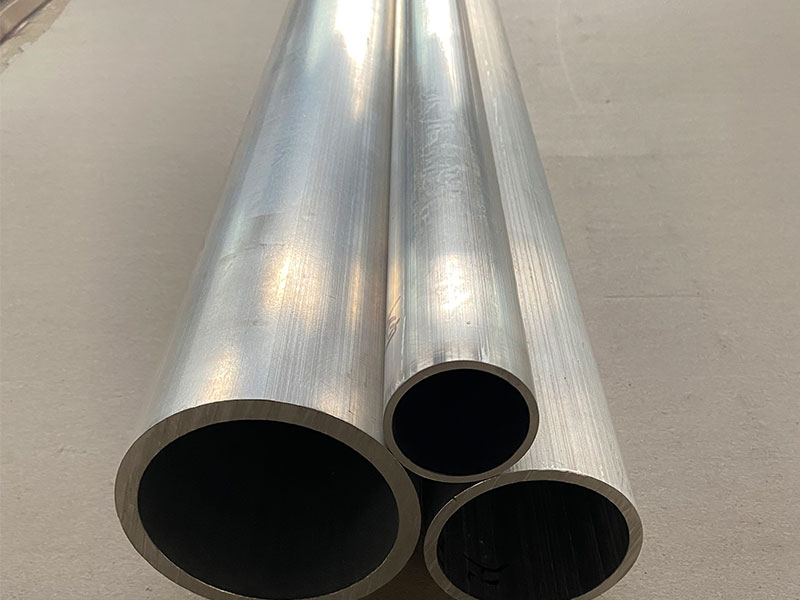

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

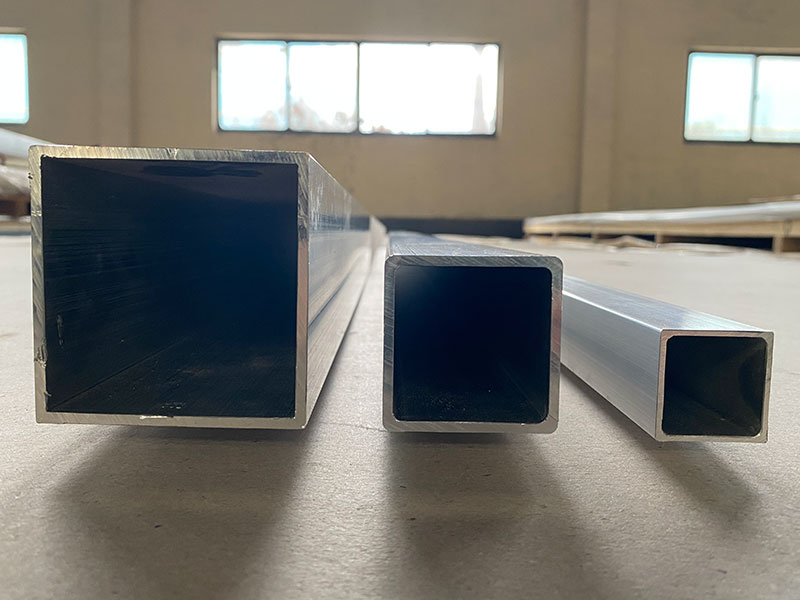

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Saltwater Environment Durability

When it comes to marine applications, durability, corrosion resistance, and mechanical performance are paramount for structural materials. Among the various aluminum alloys available, 5083 aluminum alloy stands out as a premium choice.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View Details5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details

Leave a Message