5083 Marine Aluminum Z Shaped Sections for Durable Marine Deck Design

5083 Marine aluminum Z-shaped sections are characterized by their high-strength properties, exceptional corrosion resistance, and light-weight nature, making them ideal for a range of marine applications, particularly in deck design.

Features

- Corrosion Resistance: 5083 aluminum exhibits superior resistance to seawater making it suitable for marine environments.

- High Strength-to-Weight Ratio: The lightweight constructs offer structural strength while minimizing weight for better fuel efficiency and payload capacity.

- Ease of Fabrication: The alloy can be easily fabricated through welding and machining procedures, making it versatile for numerous installations.

- Tempering Options: The various temper options provide for wider application potential and adaptability in marine engineering designs.

Applications

5083 Marine aluminum Z-shaped sections are widely used in:

- Marine Decking: Used as structural support components on vessels to provide optimal grounding and safety.

- Shipbuilding & Repair: Providing high strength and stability essential for ship frames and load-bearing structures.

- Luxury Yachts: Used for aesthetic features and decking in high-end marine vessels, capitalizing on both appearance and functional strength.

- Floating Bodies & Barges: Efficient in creating stable, robust vessel frameworks suitable for various body contours and layouts.

Technical Specifications

The specifications below dwell into the specific parameters of 5083 marine aluminum Z sections:

| Property | Specification |

|---|---|

| Alloy | 5083 |

| Temper | H116, H321 |

| Thickness Range | 6.0 mm - 50.0 mm |

| Width Range | 50 mm - 300 mm |

| Length | Customizable (up to 9m) |

| Material Standard | ASTM B928, EN 573, EN 485 |

| Strength | Yield strength: ≥ 235 MPa |

| Tensile strength | 290 - 300 MPa |

| Elongation at Break | > 15% |

Chemical Composition

The chemical properties contribute immensely to performance; as outlined in the table below:

| Element | Min (% w/w) | Max (% w/w) |

|---|---|---|

| Aluminum (Al) | Bal. | Bal. |

| Magnesium (Mg) | 4.0 | 4.9 |

| Manganese (Mn) | 0.4 | 1.0 |

| Chromium (Cr) | 0.05 | 0.25 |

| Zinc (Zn) | 0.0 | 0.2 |

| Copper (Cu) | 0.0 | 0.1 |

| Silicon (Si) | 0.0 | 0.2 |

| Iron (Fe) | 0.0 | 0.4 |

Related Products

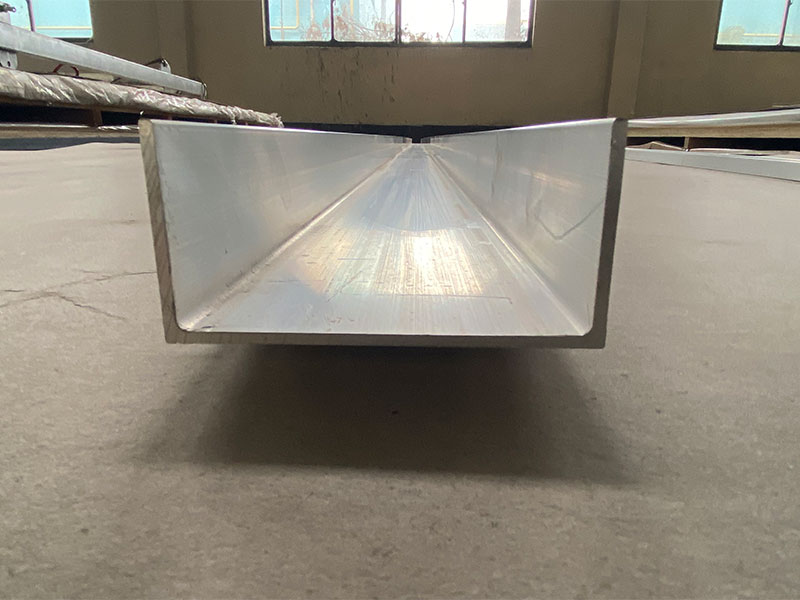

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

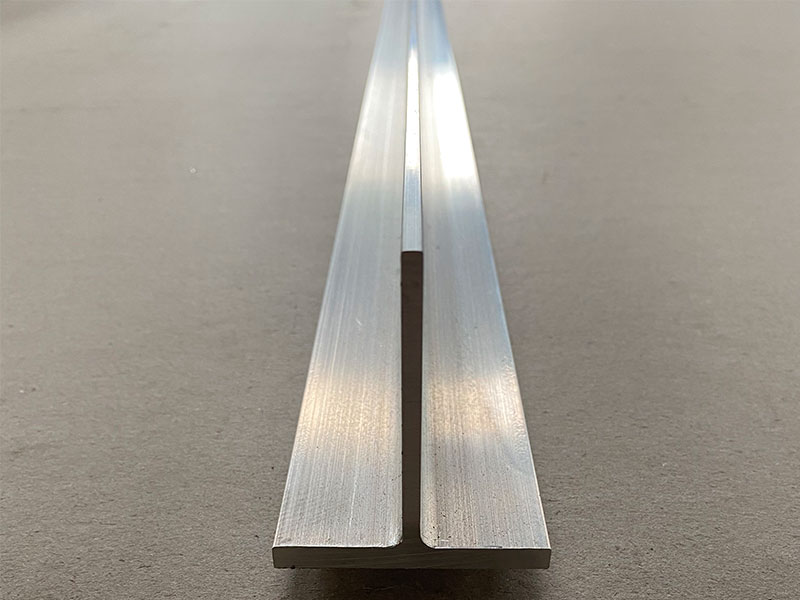

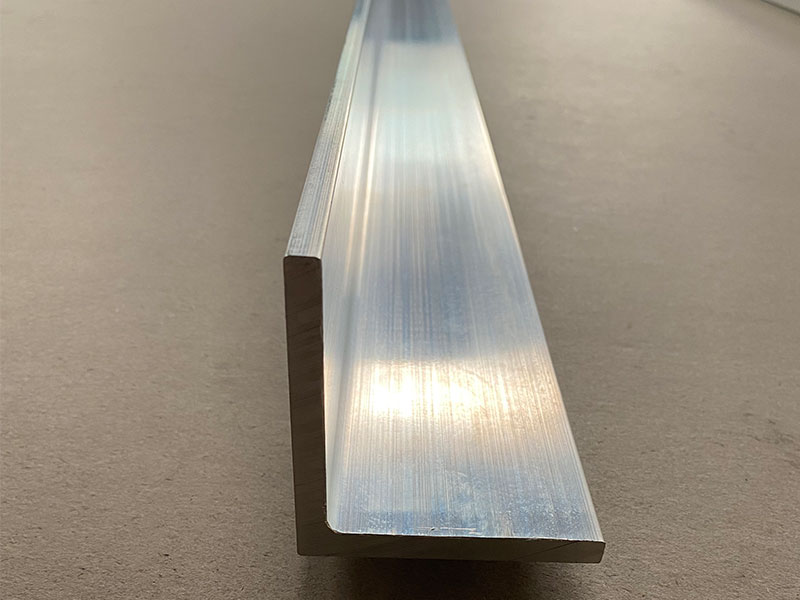

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

5083 Marine Aluminum Z Shaped Sections for Custom Marine Boat Parts

When it comes to constructing durable, lightweight, and corrosion-resistant components for marine vessels, material selection is crucial. 5083 Marine Aluminum Z Shaped Sections offer an optimal combination of strength, formability.

View Details5083 Marine Aluminum Channels for Lightweight Marine Vessel Design

5083 Marine Aluminum Channels for Lightweight Marine Vessel Design: A Perfect Fusion of Strength, Durability, and Corrosion ResistanceIn the evolving world of marine vessel design, the quest for materials that offer unbeatable strength.

View Details5083 Marine Aluminum Round Bar for Custom Coastal Marine Engineering

When it comes to custom coastal marine engineering, material selection is crucial for ensuring durability, strength, and resistance to harsh marine environments.

View Details5083 Marine Aluminum Channels for Lightweight Boat Deck Design

The marine industry continually seeks efficiency and versatility in boat construction. Among the materials available, 5083 marine aluminum channels have emerged as a stellar choice for lightweight boat deck design.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View Details

Leave a Message