5083 Marine Aluminum Angles for Seawater Proof Boat Frame Parts

5083 Marine aluminum angles are purpose‑designed profiles for high‑strength, corrosion‑resistant boat and ship structures. Based on the Al‑Mg 5083 alloy, these angles are widely used in hull framing, deck reinforcement, and superstructure supports where long‑term exposure to seawater is expected.

5083 is a non‑heat‑treatable aluminum–magnesium alloy with excellent seawater corrosion resistance and good weldability. When extruded into angle profiles (L‑shaped sections), it combines alloy performance with structural efficiency.

Typical angle forms:

- Equal angles: e.g., 50×50, 75×75, 100×100 mm

- Unequal angles: e.g., 50×30, 80×50 mm

- Standard thickness range: 3–12 mm (custom on request)

- Typical tempers: O, H111, H112, H116, H321 (marine tempers)

2. Features and Benefits

2.1 Main Performance Advantages

Seawater corrosion resistance

High magnesium content and controlled impurities provide outstanding resistance in:- Offshore and coastal environments

- Immersed and splash zones

- Brackish water and high‑chloride atmospheres

High strength‑to‑weight ratio

Compared with 5000‑series general‑purpose alloys, 5083 in marine tempers offers:- Higher yield and tensile strength

- Reduced frame weight for the same structural capacity

Excellent weldability

Suitable for MIG and TIG welding with minimal loss of strength and very good resistance to stress‑corrosion cracking.Good toughness and impact resistance

Important for high‑speed hulls, patrol boats, and workboats exposed to dynamic loads and wave impact.Non‑magnetic and spark‑free

Ideal for applications around sensitive navigation equipment or where spark risk must be minimized.

2.2 User Benefits

- Longer service life in seawater

- Reduced maintenance compared with steel (no rust, easier inspection)

- Weight reduction vs. steel beams and angles, helping improve fuel efficiency and payload

- Faster fabrication and simplified installation thanks to easy cutting, drilling, and welding

3. Chemical Composition of 5083 Alloy

Typical composition limits for 5083 (weight %):

| Element | Symbol | Typical Range (%) | Function in Alloy |

|---|---|---|---|

| Magnesium | Mg | 4.0 – 4.9 | Primary strengthening element; improves corrosion resistance |

| Manganese | Mn | 0.4 – 1.0 | Improves strength and fatigue resistance |

| Chromium | Cr | 0.05 – 0.25 | Enhances corrosion resistance, grain control |

| Iron | Fe | ≤ 0.40 | Controlled impurity; excessive Fe can reduce toughness |

| Silicon | Si | ≤ 0.40 | Controlled impurity |

| Copper | Cu | ≤ 0.10 | Kept very low to improve corrosion resistance |

| Zinc | Zn | ≤ 0.25 | Limited to avoid stress‑corrosion cracking |

| Titanium | Ti | ≤ 0.15 | Grain refiner during casting |

| Others (each) | — | ≤ 0.05 | Traces only |

| Total Others | — | ≤ 0.15 | — |

| Aluminum | Al | Balance | — |

4. Mechanical Properties (Typical)

Mechanical properties will vary with temper and thickness, but the following values are typical for marine service tempers. Values are for reference only and can be tailored by specific standards (e.g., ASTM B221, EN 755).

4.1 Typical Mechanical Properties

| Property | Unit | 5083‑O (Soft) | 5083‑H111 | 5083‑H116 / H321* |

|---|---|---|---|---|

| Tensile Strength, Rm | MPa | 270 – 340 | 275 – 345 | 305 – 380 |

| Yield Strength, Rp0.2 | MPa | 120 – 160 | 145 – 215 | 215 – 300 |

| Elongation (A50, typical) | % | 16 – 20 | 12 – 18 | 10 – 16 |

| Brinell Hardness (HBW) | HB | ~75 | 75 – 85 | 90 – 100 |

| Modulus of Elasticity | GPa | ~70 | ~70 | ~70 |

| Shear Strength (approximate) | MPa | 80 – 110 | 90 – 125 | 110 – 140 |

| Fatigue Strength (10⁷ cycles)** | MPa | — | ~90 – 100 | ~100 – 110 |

* H116 and H321 are strain‑hardened and stabilized tempers optimized for marine plates and profiles.

** Rotating‑bending fatigue, for guidance only.

5. Typical Angle Sizes and Technical Specifications

The following table summarizes frequently used 5083 Marine aluminum angles for boat frame parts. Custom dimensions are available according to drawings.

5.1 Common Dimensional Range

| Parameter | Unit | Typical Range / Notes |

|---|---|---|

| Leg length (equal angle) | mm | 30 – 150 |

| Long leg (unequal angle) | mm | 40 – 200 |

| Short leg (unequal angle) | mm | 20 – 120 |

| Thickness | mm | 3 – 12 (up to 20 mm on request) |

| Standard length | m | 4.0, 5.8, 6.0, 12.0 (cut‑to‑length available) |

| Angle tolerance | degrees | ±1° typical, tighter on request |

| Straightness tolerance | mm/m | ≤ 1.5 (per EN / ASTM guidelines) |

| Squareness of legs | mm | ≤ 1.0 deviation over leg width |

| Surface condition | — | Mill finish, shot‑brushed, or anodized |

5.2 Example Size and Weight Table (Equal Angles, 6 m Length)

| Size (A×B×t) mm | Cross‑Section Area (cm²) | Approx. Weight (kg/m) | Weight per 6 m (kg) |

|---|---|---|---|

| 40×40×4 | 3.00 | 0.81 | 4.86 |

| 50×50×5 | 4.65 | 1.26 | 7.56 |

| 60×60×6 | 6.66 | 1.81 | 10.86 |

| 75×75×6 | 8.52 | 2.32 | 13.92 |

| 100×100×8 | 14.4 | 3.93 | 23.58 |

Values are indicative and based on theoretical density (≈ 2.66–2.70 g/cm³).

6. Corrosion and Seawater Performance

6.1 Seawater Resistance

5083 alloy has been extensively used in:

- Hull plating and framing of workboats, ferries, patrol boats

- Offshore platform structures and gangways

- Brine tanks and desalination equipment

Corrosion behavior:

|-----------------------------------|-----------------------------------------------|| Fully immersed in seawater | Very good; low general corrosion rate || Splash / tidal zones | Excellent, especially in H116/H321 tempers || Marine atmosphere (coastal) | Very good; minimal pitting with proper design || Galvanic couple with steel | Needs isolation (gaskets, coatings, sleeves) |

6.2 Recommended Protection Practices

- Use insulating pads or sleeves when connecting to carbon steel frames or stainless fittings.

- Apply marine‑grade coatings or anodizing in highly aggressive environments or for aesthetic requirements.

- Avoid crevice traps where stagnant seawater may concentrate salts.

7. Processability and Fabrication

7.1 Cutting and Machining

- Easily cut by:

- Band saw

- Circular saw with carbide blades

- Waterjet or plasma (with heat‑affected zone control)

- Good machinability for drilling, milling, and slotting.

7.2 Forming and Bending

- 5083 can be cold‑formed, but minimum bend radius should be respected to avoid cracking, especially in harder tempers (H116/H321).

- For tight radii or complex shapes, local annealing or using O/H111 temper is recommended.

7.3 Welding

| Aspect | Recommendation |

|---|---|

| Main process | MIG (GMAW) for production welding |

| Alternative | TIG (GTAW) for precision joints |

| Typical filler | ER5183, ER5356 (matching Mg content) |

| Post‑weld treatment | Usually none; natural aging only |

| Weldability rating | Excellent for marine structures |

8. Typical Marine Applications

5083 Marine aluminum angles are used in almost every structural part of an aluminum vessel:

8.1 Boat Frame and Hull Structure

- Longitudinals and stringers along hull plating

- Transverse frames and ribs for small and medium boats

- Bulkhead stiffeners to increase panel rigidity

- Keel and chine reinforcements where impact loads are higher

8.2 Decks, Superstructures, and Outfitting

- Deck edge and opening framing (hatches, manholes, doors)

- Cabin walls and roof frames

- Handrail posts and guardrail framing (with appropriate finishing)

- Support frames for navigation lights, antennas, and radars

8.3 Workboat and Offshore Equipment

- Skid frames and equipment supports on deck

- Walkway and gangway side members

- Davit and small crane sub‑structures (non‑critical parts)

- Racks for pipelines, hoses, and cable trays in marine plants

By replacing steel with 5083 aluminum angles in these areas, operators can significantly reduce vessel weight, improve speed and fuel efficiency, and lower lifetime maintenance expenses.

9. Selection Guidelines for Boat Frame Design

When choosing 5083 angles for a marine structure, consider:

| Design Factor | Recommendation / Consideration |

|---|---|

| Load type | Bending, compression, shear, or combined? |

| Structural class rule | Verify dimensions against ABS, DNV, LR, or similar rules |

| Corrosion allowance | Normally minimal for aluminum, but consider wear margins |

| Welding configuration | Leg used as web or flange; joint access for welding |

| Stiffener spacing | Match angle size to panel thickness and spacing |

| Service environment | Coastal, fully immersed, or fresh water |

Using basic structural formulas (section modulus, area moment of inertia), designers can quickly compare angle sizes and select the lightest profile that still meets safety margins and classification requirements.

5083 Marine aluminum angles combine:

- Proven seawater resistance for long‑life hull and deck structures

- High strength with low weight, improving vessel efficiency

- Excellent weldability and fabrication flexibility

- Versatile profiles for frames, stiffeners, and support members

- Lower maintenance compared to carbon steel structures in the same environment

For customers building or refitting boats, ferries, workboats, or offshore equipment, 5083 Marine aluminum angles are a reliable, standards‑compliant choice that provides robust structural performance with minimized lifecycle cost in aggressive seawater conditions.

Related Products

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum channels

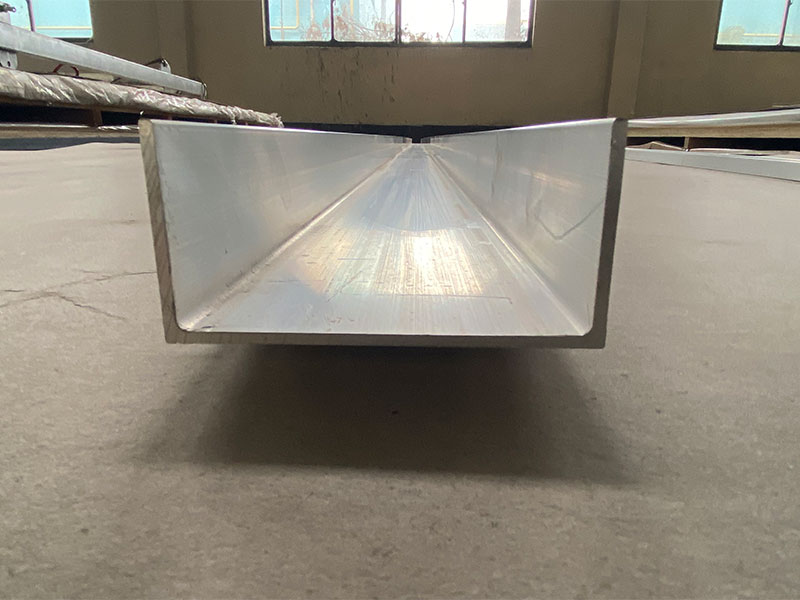

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

5083 Marine Aluminum Z Shaped Sections for Offshore Vessel Frame Design

In the demanding offshore marine environment, the structural integrity and corrosion resistance of vessels are crucial for reliable performance and safety.

View Details5083 Marine Aluminum Round Bar for Custom Boat Hull Design

Designing the perfect boat hull involves a harmony of creativity, functionality, and the right materials. When it comes to marine engineering, 5083 Marine Aluminum Round Bar stands tall, due to its strength, corrosion resistance.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details5083 Marine Aluminum Round Bar for Durable Offshore Vessel Parts

When it comes to constructing durable offshore vessel parts, material choice is paramount. Among various options, 5083 marine aluminum round bar stands out as a highly reliable and versatile solution.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View Details

Leave a Message