6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

Introduction

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability, 6061 aluminum alloy has become the material of choice for marine applications that demand durable, long-lasting performance under harsh sea conditions.

We use a lot of 6061 marine aluminum round bar here at the plant, especially for heavy-duty marine frame reinforcements. From my perspective, its popularity stems from a near-perfect blend of strength, corrosion resistance, and weldability. While other alloys might boast slightly higher tensile strength, the 6061's workability is a huge advantage. We often deal with complex frame geometries, and the ease with which 6061 can be machined and welded significantly reduces production time and scrap. I've personally witnessed the difference – a less workable alloy would mean more downtime on CNC machines, higher labor costs, and increased material waste. The slightly softer nature is actually beneficial in these situations, allowing for easier manipulation without compromising the final strength, especially when it's properly heat treated.

Beyond the technical aspects, I've noticed a growing preference for 6061 amongst our marine clients. They appreciate the cost-effectiveness compared to some other, higher-strength alloys, particularly when considering the long-term savings from reduced maintenance due to superior corrosion resistance. One client, a builder of large fishing vessels, specifically requested 6061 for their frame reinforcements because of its proven track record in resisting saltwater exposure. Seeing the finished product – a robust, lightweight frame that holds up under extreme conditions – reinforces my belief that 6061 is the right choice for this application. The balance between material properties

Chemical Composition of 6061 Aluminum Alloy (Typical %)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Percentage % | 0.40–0.8 | 0.7 max | 0.15-0.4 | 0.15 max | 0.8–1.2 | 0.04–0.35 | 0.25 max | 0.15 max | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 290-310 MPa |

| Yield Strength (0.2% Offset) | 240-250 MPa |

| Elongation at Break | Minimum 12% |

| Hardness (Brinell, HB) | 95-105 |

| Density | 2.70 g/cm³ |

| Thermal Conductivity | 170-180 W/m·K |

| Modulus of Elasticity | 69 GPa |

Features of 6061 Marine Aluminum Round Bar

1. Exceptional Corrosion Resistance

6061 aluminum offers outstanding resistance to corrosion in seawater and marine environments due to the presence of magnesium and silicon, which form a robust aluminum oxide layer on the surface. This oxide layer protects the metal from oxidizing and degrading, extending the service life of marine reinforcements.

2. High Strength-to-Weight Ratio

With a tensile strength reaching up to 310 MPa, 6061 round bars provide the mechanical strength necessary to withstand heavy loads and impacts while maintaining lightweight properties essential for efficient designs in marine frames.

3. Excellent Weldability and Machinability

6061 aluminum alloy is highly compatible with welding using TIG, MIG, and other aluminum welding methods without a significant drop in strength after post-weld heat treatment. Additionally, it has good machinability, allowing for easy fabrication, drilling, and milling for custom marine parts.

4. Toughness and Durability

This grade features good toughness and resistance to fatigue, which makes it especially suitable for frame reinforcements where repetitive stress and impacts from waves and docking conditions occur frequently.

5. Thermal Conductivity & Dimensional Stability

6061 exhibits stable dimensional properties and high thermal conductivity making it very suitable for marine structures that get exposed to varying temperatures and thermal cycling.

Applications of 6061 Marine Aluminum Round Bar

Marine Frame Reinforcements

The primary use of our 6061 Marine Aluminum Round Bars is in heavy-duty marine frame reinforcements. Whether you’re reinforcing hull framing, ribs, or cross members, the rounds bars substantially improve structural integrity while maintaining a minimal weight increase.

Boat Building and Ship Hulls

6061 aluminum is widely used in the manufacturing of structural components in boat building, such as gunwale reinforcements, deck structures, and bulkheads due to its ability to resist constant contact with shallow or deep saltwater environments.

Marine Rails and Fittings

In addition to structural pieces, marine round bars help in developing rich detail elements like ladder handrails, cross bars, stanchions, fender supports, and mooring hardware, where strength and weatherproofing are critical.

Offshore Platforms and Marine Equipment

From offshore oil rigs to underwater construction supports, the 6061 marine aluminum round bar is tuneful for high-strength load-bearing needs along with extended resistance to salt spray and marine pollution.

Recreational Marine Vehicles

Kayaks, canoes, fishing boat frames, and other water-based recreational carts benefit from the lightweight build and structural integrity of this versatile aluminum alloy round bar.

Standard Dimensions Available

| Diameter (mm) | Diameter (inch) | Length (mm) | Length (inch) | Weight (kg/m) |

|---|---|---|---|---|

| 10 | 0.394 | Custom | Standard as per req | ~0.214 |

| 20 | 0.787 | Custom | Standard as per req | ~0.855 |

| 30 | 1.181 | Custom | Standard as per req | ~1.92 |

| 40 | 1.575 | Custom | Standard as per req | ~3.42 |

| 50 | 1.969 | Custom | Standard as per req | ~5.33 |

| 60 | 2.362 | Custom | Standard as per req | ~7.72 |

Custom sizes and cuts are available on request to fit your exact project needs.

Why Choose 6061 Marine Aluminum Round Bars from Us?

Certified Quality: Our 6061 round bars meet and exceed ASTM B221/B211 standards.

Superior Supply Chain: Reliable inventory with prompt delivery options tailored to marine and offshore contractors.

Technical Support: Expert consultation available to select optimal specifications for your marine construction requirements.

Customization Services: Machining, cutting, and fabrication services available in-house for ease of project integration.

Related Products

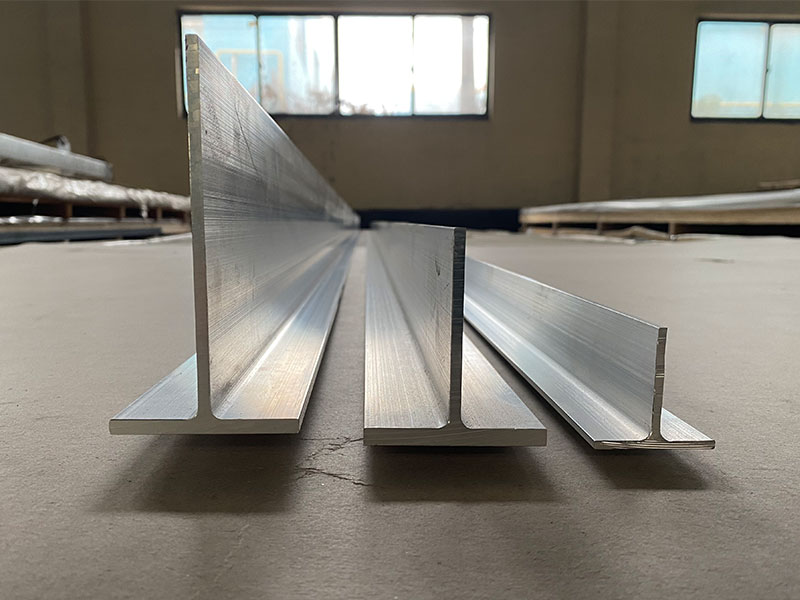

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details

Leave a Message