6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

In the coastal shipbuilding industry, the demand for materials that combine strength, durability, and corrosion resistance is paramount. The 6061 Marine Aluminum Round Bar emerges as an ideal solution, offering a premium balance of mechanical performance and resistance to harsh marine environments. Engineered with precision alloying elements and processed under stringent quality controls, this product caters specifically to modern lightweight coastal vessels where weight reduction and longevity are crucial.

6061 aluminum is a precipitation-hardened alloy notable for its balanced properties, mostly comprising magnesium and silicon. Its use in the maritime sector is extensive due to excellent resistance to saltwater corrosion and favorable strength-to-weight ratios. The round bar form factor facilitates easy handling and machinability, making it exceptional for structural frames, fittings, railings, masts, and other critical components within a shipbuilding framework.

Chemical Composition (Weight %)

| Element | Content Range (%) |

|---|---|

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.40 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.05 combined |

| Aluminum (Al) | Balance |

This balanced composition grants the alloy sufficient hardness, tensile strength, and corrosion resistance essential for harsh marine atmospheres.

Mechanical Properties by Temper State

6061 Aluminum’s mechanical parameters vary by temper:

| Temper | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness (HB) |

|---|---|---|---|---|

| O (Annealed) | 90 - 140 | 55 - 95 | ≥ 16 | 30 - 50 |

| T4 (Solution Heat Treated) | 190 - 250 | 130 - 180 | ≥ 10 | 50 - 70 |

| T6 (Solution Heat Treated + Artificial Aging) | 280 - 310 | 240 - 275 | ≥ 8 | 95 - 115 |

In marine applications, T6 temper is usually preferred due to its enhanced strength combined with good corrosion resistance.

Industry Standards & Implementation

- ASTM B211 – Standard Specification for Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod, and Wire

- AMS QQ-A-200/11 – Specification for Aluminum Alloy Bar, Rod and Wire

- ISO 6361-2 – Wrought aluminum alloys - Sheets, strips and plates for marine structures

Our 6061 marine aluminum round bars meet or exceed these standards, ensuring full traceability, mill certificate conformity, and rigorous quality assurance protocols.

Advantages in Coastal Shipbuilding

- Lightweight Strength: Provides exceptional structural integrity while reducing overall vessel weight, enhancing fuel efficiency and speed.

- Corrosion Resistance: Forms a passive oxide layer which protects underlying metal from saltwater damage, significantly prolonging service life in marine conditions.

- Machinability: Easy to fabricate by machining, welding, or annealing, allowing complex shapes and fittings to be constructed cost-effectively.

- Versatile Size Range: Round bars are available in diameters ranging typically from 10 mm to 250 mm (0.4” to 10”), supporting diverse design requirements.

- Environmental Adaptability: Suitable for both commercial coastal vessels and lightweight military crafts exposed to saline fog, sulfur compounds, and humidity.

Recommendations for Use and Processing

- Welding Considerations: Preferred welding techniques include TIG and MIG by skilled operators familiar with aluminum; post-weld heat treatments may enhance joint strength.

- Surface Treatment: Anodizing or applying marine-grade coatings to further bolster corrosion resistance is suggested based on application environment.

- Thermal Stress Management: Avoid rapid quenching incompatible with temper specifications to retain mechanical attributes.

- Storage: Store in clean, dry environments separated from copper or steel to prevent galvanic corrosion.

Related Products

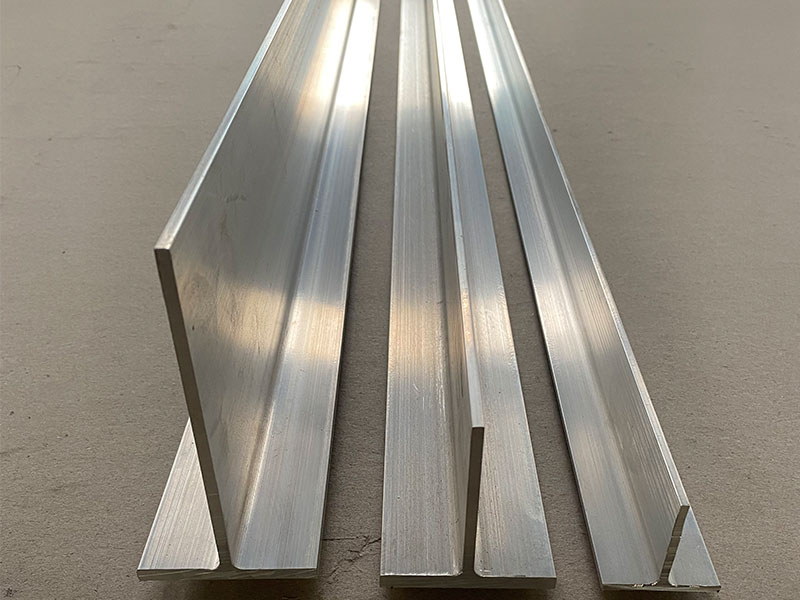

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details

Leave a Message