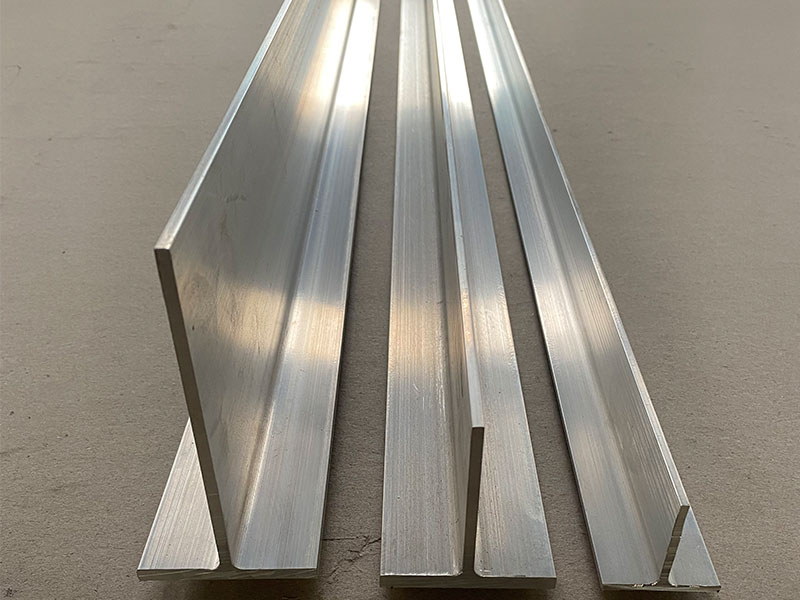

6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance, and adaptability essential for resilient marine infrastructure in harsh coastal environments.

6061 Marine Aluminum Channels: Unique Functions in Coastal Engineering

6061 aluminum channels serve as fundamental structural elements in bridges, seawalls, docks, offshore platforms, and other coastal installations. Unlike conventional steel that suffers from rust, especially when exposed to salty seawater and moist air, 6061 marine aluminum offers superior corrosion resistance with high mechanical strength, making it ideal for critical marine applications.

Functional Attributes:

- Structural Support: Channels provide a sturdy, weight-optimized backbone framework in platforms and piers, helping to evenly distribute dynamic and static loads.

- Corrosion Resistance: Action against chloride-induced pitting is vital near oceans. The presence of magnesium and silicon in 6061 creates a robust passive oxide layer, impeding saltwater-induced corrosion.

- Lightweight Versatility: 6061 channels are more manageable and easier to manipulate on-site compared to heavier steel, facilitating assembly and reducing logistical constraints.

- Compatibility with Fixtures: Precisely extruded profiles allow absolute fitting of fasteners, braces, and cross-members, ensuring stable construction adaptable to variable environmental loads (like strong coastal winds and salinity variations).

Parameters & Dimensional Specifications

6061 Aluminum Channels come according to ASTM B221 for extruded aluminum profiles, commonly tailored for marine engineering projects under the broader ASTM B928 specification for marine-grade aluminum alloys. The typical dimensions and mechanical properties include:

| Property | Description / Typical Value |

|---|---|

| Composition | Aluminum (Al) alloy with Mg (0.8–1.2%), Si (0.4–0.8%) |

| Alloy Tempering | T6 (solution heat-treated and artificially aged) |

| Yield Strength (0.2% offset) | ≥ 240 MPa (35,000 psi) |

| Ultimate Tensile Strength | ≥ 290 MPa (42,000 psi) |

| Elongation at Break | ≥ 10-12% (indicative ductility) |

| Density | ~2.7 g/cm³ |

| Corrosion Resistance | Excellent against seawater (ISO + ASTM salt spray tested) |

| Common Thickness Range | 3 mm to 50 mm and custom sizing on request |

| Lengths Available | Cut-to-size typically up to 6 meters standard |

Chemical Composition in Detail

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (typically ~97.9%) |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | Max 0.7 |

| Copper (Cu) | Max 0.15 |

| Manganese (Mn) | Max 0.15 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | Max 0.25 |

| Titanium (Ti) | Max 0.15 |

This balanced alloy chemistry offers resistance to intergranular corrosion and maintains mechanical integrity under fluctuating coastal temperatures and environmental stresses.

Alloy Tempering and Its Importance

The most common temper for 6061 marine aluminum channels is T6, achieved via:

- Solution heat treatment at approximately 530°C, dissolving alloying compounds.

- Quenching rapidly in water to retain a supersaturated solid solution.

- Artificial aging at roughly 175°C to precipitate strengthening phases, enabling a exceptionally high strength-to-weight ratio.

This temper results in enhanced yield and tensile strengths, highly energetic enough to withstand sustained impacts and load cycles typically encountered by infrastructure bordering the wild seas.

Application Standards and Best Practices

The magnesium-silicon rich 6061 marine aluminum aligns with:

- ASTM B221 - Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- ASTM B928 - Specification for Marine Aluminum alloys, ensuring seaworthy quality.

- ISO 9227 - Overall testing for salt spray corrosion standards to validate performance for coastal residues.

- AWS D1.2 or equivalent for appropriate marine weldability, especially when used in welded structures connecting channels and other framing members.

Ensuring fabrication aligns with these criteria maintains both mechanical properties and corrosion resistance for the lifespan of the marine works.

Distinctive Implementation Insights

In high-strength coastal engineering projects, 6061 marine aluminum channels serve beyond simple strip supports—they act as critical nodes enabling:

- Modular assembly of floating platforms, combining ease of replacement with durable construction.

- Customized extrusions applied as fixture rails for heavy lifelines and equipment tie-downs.

- Cold-formed, extruded bends, supporting variable directional load paths essential when unpredictable wave and wind forces intervene.

- Compatible use with composite decking and fiberglass-reinforced polymers, spreading loads with minimal deformation over vast spans.

Hence, the 6061 marine aluminum channel goes beyond a mere structural support element—it's a pivotal adaptable feature shaping the resilience of coastal engineered structures.

Final Thoughts

In the sphere of contemporary coastal engineering, 6061 marine aluminum channels throw in a robust punch combining strength, corrosion resilience, and adaptable engineering versatility. With precise chemistry, expert alloy tempering, and adoption under stringent ASTM marine standards, these channels epitomize progress in applications aiming for multi-decade service life under punishing coastal environmental dynamics.

Investing in 6061-grade marine aluminum channels translates into safer, lighter, cost-efficient, and drastically more durable infrastructure—a must for engineers devising future-proof coastal solutions.

For inquiries about custom 6061 marine aluminum channels suitable for coastal engineering or architectural marine projects, connect with our aluminum expertise team today. Reimagine strength where the ocean touches the land.

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

6061 Marine Aluminum Round Bar for Custom Marine Frame Fabrication

Marine environments are unforgiving — they demand resilience, lightweight strength, and excellent corrosion resistance from the materials we use in boat and frame fabrication.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details

Leave a Message