6061 Marine aluminum angles

6061 Marine aluminum angles are among the most popular and versatile aluminum alloy products used in marine and structural engineering applications. Renowned for their excellent strength, corrosion resistance, and machinability, these aluminum angles provide a durable foundation for builders and engineers working in harsh marine environments.

Table of Contents

- Features of 6061 Marine aluminum angles

- Chemical Composition

- Mechanical Properties

- Technical Specifications

- Advantages and Benefits

- Typical Applications

- Conclusion

6061 marine aluminum is an aluminum-magnesium-silicon alloy widely acknowledged for superior corrosion resistance in seawater environments, making it ideal for marine structure fabrication. When formed into angles (L-shaped sections), this alloy provides excellent angular support and stability in boat building, dock construction, and offshore platforms.

6061 alloy’s balance of strength, weldability, and corrosion resistance ensures long-lasting performance while maintaining lightweight construction, enabling increased fuel efficiency and easier installation.

Features of 6061 Marine aluminum angles

- High Strength-to-Weight Ratio: Provides strong structural performance without excess weight.

- Excellent Corrosion Resistance: Enhanced protection against saltwater and marine atmosphere corrosion.

- Good Weldability: Enables secure connections with minimal heat distortion.

- Versatile Fabrication: Suitable for cutting, bending, drilling, and machining without brittleness.

- Heat-Treatable: Strength and hardness can be improved through heat-treatment processes like T6 tempering.

- Low Maintenance: Corrosion resistance reduces the frequency and cost of repairs.

- Recyclable: Environmentally friendly option due to its recyclability.

Chemical Composition

Note: Percent compositions can have minor variations depending on manufacturing standards and material suppliers.

Mechanical Properties

Technical Specifications of 6061 Marine aluminum angles

Advantages and Benefits

Typical Applications

6061 Marine aluminum angles are ideal across many marine-related sectors:

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

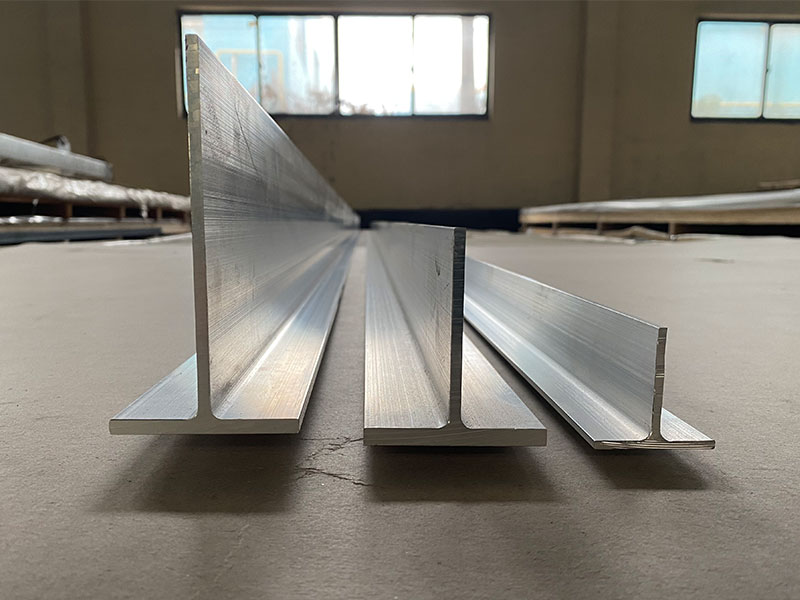

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum Channels for Offshore Boat and Platform Construction

6061 Marine Aluminum Channels are a premier choice for offshore boat and platform construction owing to their combination of strength, corrosion resistance, and excellent workability.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine Aluminum Angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details

Leave a Message