6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

6061 aluminum is a precipitation-hardened alloy, mainly comprising magnesium and silicon as major alloying elements, yielding exceptional strength and corrosion resistance particularly advantageous in marine conditions. When treated to a T6 temper, the alloy undergoes solution heat treatment and artificial aging, achieving optimal mechanical performance.

- Type: Aluminum Alloy – 6061

- Temper: T6 (Solution Heat Treated & Artificially Aged)

- Corrosion Resistance: Excellent, especially suitable for marine atmosphere and saltwater exposure

- Weldability: Excellent, weldable by most common welding processes without pre- or post-heating

- Fabrication: High machinability and formability compared to other high-strength alloys

2. Material Parameters and Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Density | 2.70 g/cm³ | ASTM B311 |

| Tensile Strength (Ultimate) | ≥ 290 MPa (42 ksi) | ASTM B209 / ASTM E8 |

| Yield Strength (0.2% offset) | ≥ 240 MPa (35 ksi) | ASTM B209 / ASTM E8 |

| Elongation (in 2 inches) | ≥ 8% | ASTM B209 / ASTM E8 |

| Hardness (Brinell) | Approximately 95 HB | ASTM E10 |

| Modulus of Elasticity | 68.9 GPa (10,000 ksi) | ASTM E1876 |

| Thermal Conductivity | ~ 167 W/m·K at 25°C | ASM Handbook |

3. Chemical Composition (wt.%)

| Element | Range (%) |

|---|---|

| Silicon (Si) | 0.8 – 1.2 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Manganese (Mn) | ≤ 0.15 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

This chemical alloying system optimally balances strength, corrosion resistance, and workability necessary for marine fabrication.

4. Tempering Process (T6 Specification)

The “T6 temper” refers to a two-step heat treatment providing the controlled precipitate microstructure that affords enhanced mechanical properties:

Step 1: Solution Heat Treating:The 6061 aluminum flat bar is heated to approximately 995°F (535°C) to dissolve soluble phases, then quenched in water for rapid cooling, preventing precipitation.

Step 2: Artificial Aging:Post solution treating, the bars are aged at approximately 320°F (160°C) for 8–24 hours to precipitate strengthening phases primarily Mg2Si, giving increased tensile and yield strength.

The process yields a strong, ductile, marine-grade product that resists deterioration even in harsh saltwater conditions.

5. Compliance to Standards

Use of 6061 T6 Marine Aluminum Flat Bars in boat frames requires compliance with international and industry codes, including but not limited to:

- ASTM B209 – Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B221 – Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- MIL-DTL-24779 – Aluminum Alloy Sheet, Plate, and Bars

- ABS, DNV-GL, IMO – Recognized marine classification societies approve 6061 for structural elements in boats and ships

- EN 573-3 – Chemical composition standards for wrought aluminum alloys

- Marine industry-specific protocols for corrosion testing and fatigue resistance.

6. Applications in Heavy Duty Boat Frame Parts

6061 T6 marine aluminum flat bars possess the precise mechanical strength, corrosion resistance, and fabrication versatility required for the following heavy duty boat frame components:

- Hull framing members and side supports

- Structural stringers

- Deck beams and reinforcements

- Bulkhead frames and fasteners

- Transom beams and flotation frame assemblies

- Supporting brackets and mounting areas for propulsion and steering systems

The combination of light weight with strength and superior oxidation resistance is vital in reducing maintenance cycles and extending vessel service life under continual marine constraints.

7. Advantages for Marine Use

- Prolonged Corrosion Resistance: Its naturally occurring oxide layer, enhanced via alloy constituents and humid tolerance, gives excellent defense in environments typical to saltwater immersion or spray.

- Strength-to-Weight Optimization: Aluminum weighs only one-third as much as steel but sustains enough structural integrity to perform where high steel strengths were traditionally required.

- Ease of Maintenance & Fabrication: Straightforward cutting, machining, welding, and thermal process adaptation enables rapid construction and repairs.

- Cost-effectiveness Over Lifecycle: Durable lifespan minimizes replacement and repair frequency, lowering total ownership expenses.

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

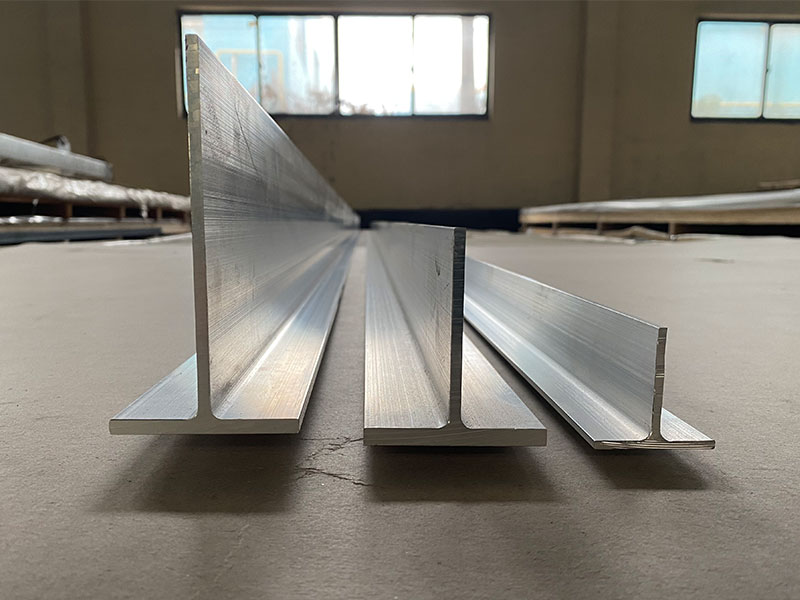

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details

Leave a Message