6061 Marine Aluminum Z Shaped Sections for Saltwater Resistant Engineering

In the world of marine construction, material selection is critical for ensuring durability, strength, and resistance to harsh environmental conditions. 6061 Marine Aluminum Z Shaped Sections have emerged as a paramount choice for various marine engineering applications owing to its excellent properties.

Features

- Corrosion Resistance: 6061 aluminum exhibits remarkable resistance to corrosion, especially in saltwater environments, ensuring extended service life.

- High Strength-to-Weight Ratio: This metal is lightweight yet incredibly strong, making it ideal for structural components that reduce overall weight without compromising stability.

- Formability: The aluminum can be easily extruded into complex shapes, providing design flexibility for engineers and architects.

- Versatility in Fabrication: Suitable for various welding, machining, and finishing operations, facilitating ease of construction.

Applications

6061 Marine Aluminum Z shaped sections are widely used across several applications, including:

- Shipbuilding and Repairs

- Structural Supports in Marine Docks and Wharf Fixtures

- Paddle and Rowing Boats

- Sailboat Masts and Rigs

- Railings and Fences in Marine Environments

Technical Specifications

Chemical Composition

The chemical properties of 6061 Marine Aluminum contribute to its favorable working characteristics. The following table outlines the general composition:

| Element | Composition (% Weight) |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.4 - 0.8 |

| Iron (Fe) | 0.0 - 0.7 |

| Copper (Cu) | 0.15 - 0.40 |

| Manganese (Mn) | 0.15 - 0.60 |

| Magnesium (Mg) | 0.8 - 1.2 |

| Chromium (Cr) | 0.04 - 0.35 |

| Zinc (Zn) | 0.0 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Other Elements | ≤ 0.05 each |

Mechanical Properties

6061 aluminum has certain mechanical properties that determine its performance characteristics.

| Property | Value |

|---|---|

| Ultimate Tensile Strength | 310 MPa (45,000 psi) |

| Yield Strength | 241 MPa (35,000 psi) |

| Elongation | 12% to 18% in 50 mm |

| Hardness (Brinell) | 95 HB |

| Density | 2.70 g/cm³ |

Alloy Tempering Conditions

To achieve optimal performance characteristics, various tempering methods are used on 6061 Aluminum.

| Temper | Treatment Temperature | Features |

|---|---|---|

| T4 | Solution Heat Treat | High strength, good corrosion resistance, workable. |

| T6 | Artificially Aged | Maximum strength with reduced ductility. |

Dimensions & Specifications for Z Shaped Sections

| Dimension | Cross Section | Weight (kg/m) ||-----------------|---------------|-------------------|| Z1 | 50 x 25 x 5 | 3.6 || Z2 | 75 x 50 x 5 | 5.5 || Z3 | 100 x 75 x 6 | 8.0 || Z4 | 125 x 75 x 8 | 10.2 || Z5 | 150 x 100 x 10 | 14.8 |Related Products

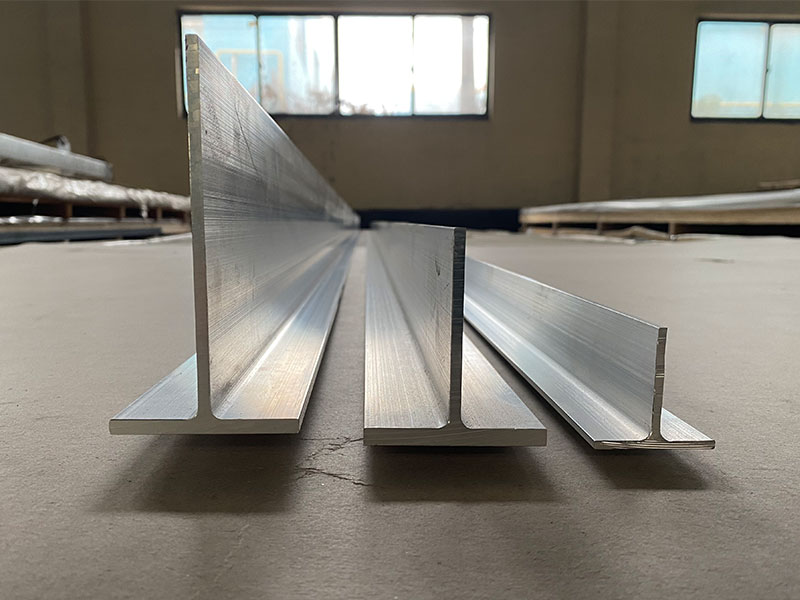

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Saltwater Resistant Engineering

In the world of marine construction, material selection is critical for ensuring durability, strength, and resistance to harsh environmental conditions.

View Details6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine Aluminum Angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details

Leave a Message