6082 Marine Aluminum Rod & Bar for Custom Boat Frame Reinforcements

Marine aluminum is the ideal choice for lightweight, durable, and corrosion-resistant applications, particularly in the production of vessels that operate in harsh marine environments. Among various aluminum alloys, 6082 stands out for boat frame reinforcements, providing robust physical and chemical properties that cater to a range of applications.

What is 6082 Marine Aluminum?

6082 is a medium-strength aluminum-silicon-magnesium alloy known for its structural integrity and an excellent resistance to corrosion. This alloy can be used effectively in highly demanding marine environments and is recognized for its potential to override weaknesses in traditional marine materials like steel.

Functions of 6082 Marine Aluminum Rod & Bar

- Strengthening Frameworks: The 6082 alloy is known for being malleable yet robust, making it an excellent candidate for custom boat frames that must resist tensions and strains at sea.

- Lightweight Construction: Aluminum rods and bars are significantly lighter than similar steel components, making toward efficient fuel mixtures and increasing speed and efficiency.

- Corrosion Resistance: With high resistance to seawater corrosion, 6082 stands the test of time and tough conditions while preserving mechanical attributes intact.

- Machinability: It offers good machinability for fabrication processes, enabling manufacturers to produce custom-designed structures.

Applications of 6082 Marine Aluminum

6082 Marine Aluminum rods and bars can be utilized in various sectors within the marine industry such as:

- Custom Boat Frame Reinforcements: Frames require immense strength, and 6082 Aluminum meets and exceeds this requirement.

- Masts and Boom Frameworks: It is widely applied in sailboats where lightweight yet durable materials are essential.

- Deck Support Beams & Gratings: Because they can withstand high loads while being resistant to corrosion in sea environments.

- Various Structural Components: Including furniture for marine applications—they fulfill in packing requirements without adding significant weight.

Technical Details and Specifications

Chemical Composition of 6082 Marine Aluminum

| Element | Percentage (Weight %) |

|---|---|

| Aluminum (Al) | 95.9 - 97.7 |

| Silicon (Si) | 0.7 - 1.3 |

| Iron (Fe) | 0.5 max |

| Copper (Cu) | 0.1 max |

| Manganese (Mn) | 0.4 - 1.0 |

| Magnesium (Mg) | 0.6 - 1.2 |

| Chromium (Cr) | 0.4 max |

| Zn | 0.2 max |

| Ti | 0.1 max |

Physical and Mechanical Properties

| Property | Value |

|---|---|

| Density | 2.70 g/cm³ |

| Ultimate Tensile Strength | 280 - 320 MPa |

| Yield Strength | 240 MPa |

| Elongation | 10 - 20% |

| Hardness (Brinell) | 70 - 90 HB |

| Melting Point | 550 - 660 °C |

Practical Implementation Standards

During the fabrication and processing of 6082, various tempering conditions are common. They help achieve specific qualities like strength and performance, represented through aluminum temper symbols.

| Temper Designation | Description | Additional Features |

|---|---|---|

| T4 | Solution heat-treated and artificially aged | Good initial strength, requires tempering for optimal characteristics |

| T6 | Solution heat-treated and artificially aged | Highest performance in strength, commonly used in final applications |

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

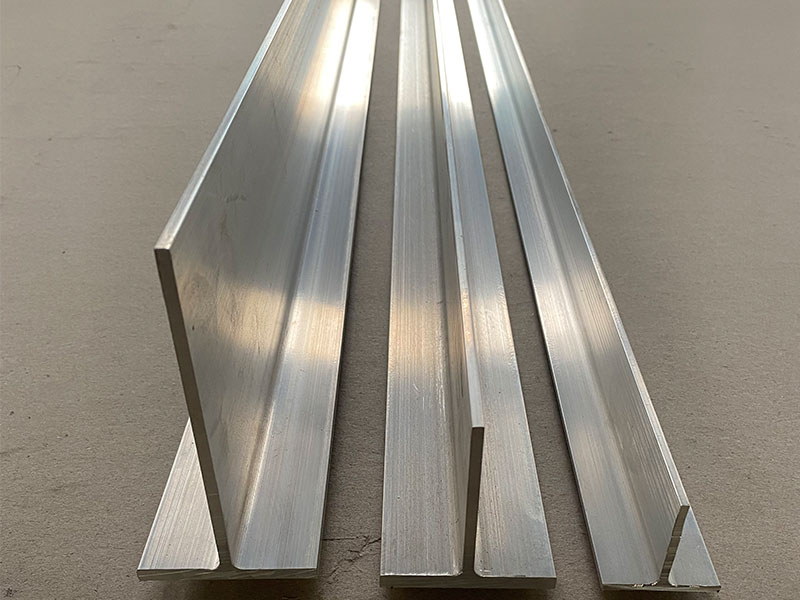

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

5083 5086 6061 6082 marine aluminum channel

IntroductionMarine aluminum channel is an essential structural product in shipbuilding, offshore platforms, marine fittings, and related coastal infrastructure. Compared with steel.

View Details6082 Marine Aluminum Rod & Bar for Custom Boat Frame Reinforcements

Marine aluminum is the ideal choice for lightweight, durable, and corrosion-resistant applications, particularly in the production of vessels that operate in harsh marine environments.

View Details6082 marine aluminum rod & bar

When it comes to marine applications, selecting the right aluminum material is crucial. Among the various alloys available, 6082 marine aluminum rod and bar is know as the premier choice, perfectly balancing strength, corrosion resistance.

View Details

Leave a Message