Marine Aluminum Fencing and Railings for Durable Offshore Platform Fencing Solutions

Marine environments impose stringent requirements on materials used in construction and infrastructure. Customarily used materials like steel or wood are prone to corrosion, wear, and decay—a glaring challenge on offshore platforms. Enter Marine aluminum fencing and railings: a robust solution that marries durability with functionality, rooted deeply in its unique physical and chemical properties. these components is crucial when specifying a suitable product for multifaceted offshore applications.

The Infrastructure Needs of Offshore Installations

The success of offshore platforms depends on secure, durable, and compliant fencing solutions. These structures must possess resistance to harsh elements like saltwater, high humidity, and fluctuating temperatures. Marine aluminum presents itself as an installation-friendly option thanks to its lightweight nature while ensuring an uncompromising level of resilience.

Index of Functions

Safety: Steel or wooden alternatives often require frequent maintenance due to corrosion or decay; in contrast, marine aluminum minimizes the need for intervention. Safety rails constructed from aluminum prevent rusting and fragmenting, pivotal on platforms located in dynamic marine environments.

Resource Efficient: The lower weight of aluminum introduces significant benefits for offshore logistic operations. Lighter materials lead to reduced transportation costs, easier installation procedures, and savings on support structures.

Aesthetic Appeal: High versatility of design translates into visually responsible railings and fences; producing not just sturdy, but illustrious installations pleasing to the eye.

Unique Technical Attributes and Alloy Tempering

Marine aluminum is frequently distinguished by its alloy composition, encompassing common varieties such as 5083, 5086, and 6061. Each alloy blends strength yet possesses specific properties geared toward certain applications. Below are relevant technical details pertaining to these compositions:

5083 Alloy: Known for its exceptional performance in extreme conditions, this alloy boasts excellent corrosion resistance. Commonly utilized in shipbuilding and hull constructions, it is impervious to stress corrosion cracking.

5086 Alloy: Built to withstand adverse marine conditions represented in boat structures. Often utilized in gas and oil environments as well as railings.

6061 Alloy: Versatile and convenient for general fabrications. Ideal for easy shaping, this variety finds its place in applications where structural strength is of paramount importance.

Chemical Properties Review: Alloy and Tempering

The viability of marine aluminum extends beyond its alloy into its heat treatment parameters; tempering defines different operational capabilities posterea. Below is a concise table outlining specification standards and tempering characteristics.

| Parameter | 5083 H111 | 5086 H116 | 6061 T6 |

|---|---|---|---|

| Yield Strength (MPa) | 200 - 300 | 240 - 285 | ≥ 260 |

| Ultimate Strength (MPa) | ≥ 305 | ≥ 310 | 310 - 360 |

| Elongation (%) | ≥ 8 | ≥ 8 | 10-20 |

| Corrosion Resistance | Excellent | Excellent | Good |

| Fatigue Strength | Good | Good | Better than Average |

The letters “H” or “T” denote the heat treatment process undertaken (H for heat treatment stability, T for solution heat-treated types) providing insight into the integrity of the material post-coating or altering functions.

Implementation Standards and Application Schemes

Incorporating marine aluminum systems must be conducted with adherence to relevant maritime standards. The following guidelines underpin quality installation protocols in the installation protocols likely to be stipulated by American Bureau of Shipping (ABS), Environments and Organization for Standardization (ISO), etc.

aspects include:

Design & Aesthetic Guideline Compliance: Ensure installations meet organization protocol for neuron-stimulating aesthetics while matching certifications for operational companies.

Commercial Standards: Satisfy international demands addressing load requirements based on design lifespan—often incorporating standards such as BS EN 1090 (fabrication integrity and quality) marking thus safeguarding against subsequent rust-trans sourced regulatory pressures.

Testing Before Deployment: Subject installed components to strength testing and corrosion coatings. Inspections pre and remedial assessments solidify the utility lifespan required by operators.

Related Products

Marine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

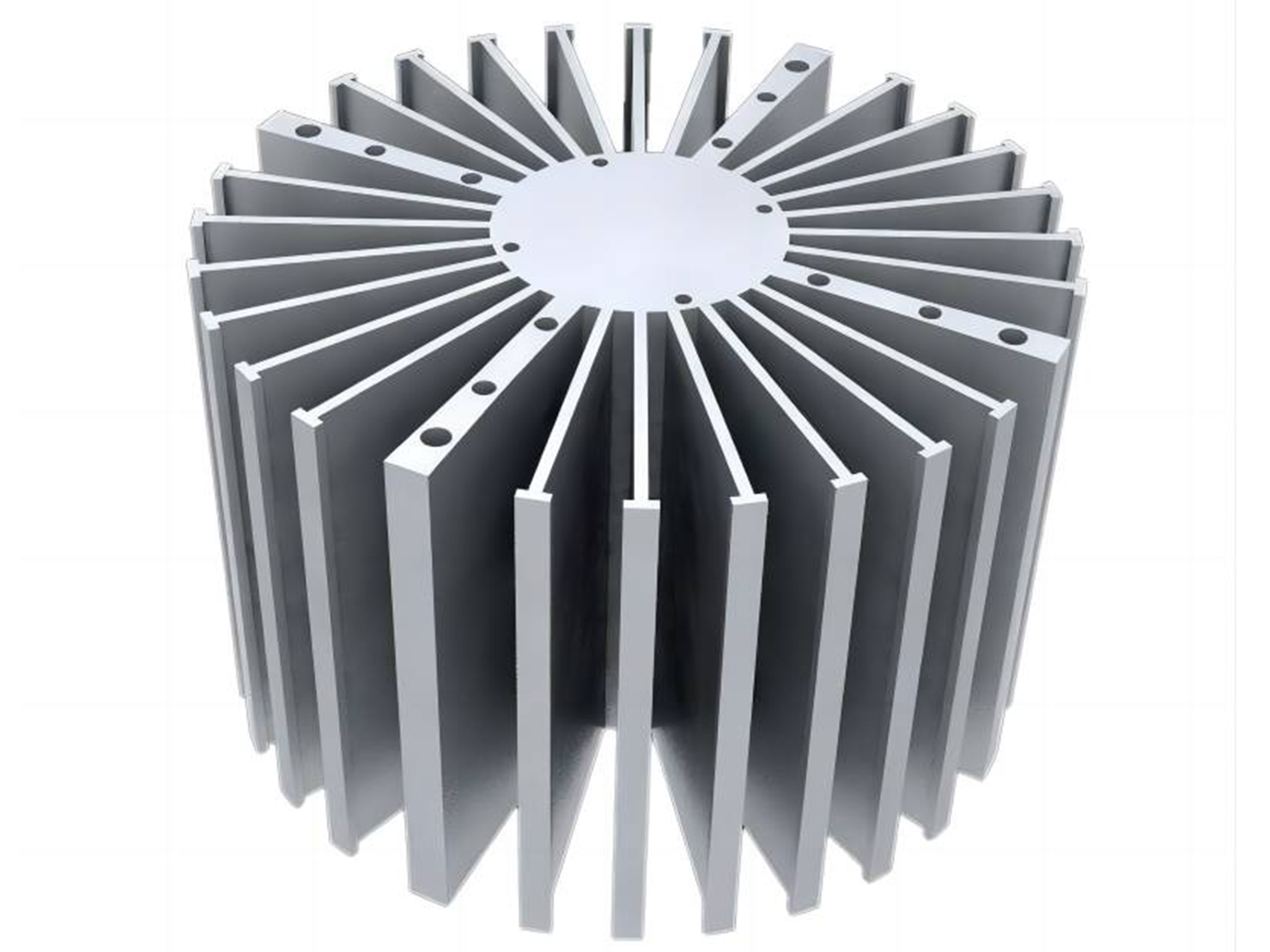

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsRelated Blog

6061 Marine Aluminum Heat Sink Profile for Custom Boat and Ship Engine Cooling

Explore the superior cooling efficiency of 6061 Marine Aluminum Heat Sink Profiles, engineered for custom boat and ship engines. detailed specifications, temper types, chemical properties, standards compliance, and advanced corrosion resistance features o

View Details6061 Marine Aluminum Customized Shapes for Seawater Resistant Offshore Construction

Aluminum alloy 6061 is widely recognized for its excellent mechanical properties, good corrosion resistance, and versatility. Specifically engineered and customized for marine and offshore construction applications.

View DetailsMarine Aluminum Heat Sink Profile for High Performance Heat Transfer in Coastal Equipment

High-performance Marine Aluminum Heat Sink Profile specially engineered for coastal equipment, offering superior corrosion resistance, thermal conductivity, and durability to ensure optimal heat transfer even in harsh marine environments.

View DetailsMarine Aluminum Customized Shapes for Custom Ship Deck and Railing Systems

In the ever-evolving maritime industry, safety, durability, and performance take precedence. Marine aluminum, recognized for its lightweight yet robust characteristics.

View DetailsMarine Aluminum Fencing and Railings for Custom Boat Deck Guardrails

Marine Aluminum Fencing and Railings: The Ultimate Choice for Custom Boat Deck GuardrailsWhen it comes to constructing custom boat deck guardrails, marine aluminum fencing and railings are emerging as the industry’s top choice.

View Details6063 Marine Aluminum Heat Sink Profile for Efficient Cooling of Offshore Equipment

In the marine and offshore industry, equipment reliability and performance hinge on effective thermal management solutions. Heat dissipation is a critical factor influencing the longevity and efficiency of sensitive offshore electronics and machinery.

View Details

Leave a Message