Aluminum Marine Elbow for Ventilation Systems in Offshore Platforms

Offshore platforms operate under demanding environments where every component must align with strict safety, durability, and performance standards. One often-overlooked yet crucial part of these systems is the Aluminum Marine Elbow used in ventilation ductwork. This specialized fitting ensures proper airflow, structural integrity, and corrosion resistance—all integral to maintaining a safe and functional offshore platform.

What is an Aluminum Marine Elbow?

An aluminum marine elbow is an angular pipe fitting fabricated from marine-grade aluminum alloys designed primarily for ventilation ducts on ships and offshore platforms. It commonly joins sections of ventilation piping at 45°, 90°, or other required angles, allowing precise redirection of airflow within the ventilation system.

Being maritime-grade means it combines strength, corrosion resistance, and light weight—attributes essential for operation on hostile sea environments. Its use in ventilation systems ensures continuous, reliable movement of fresh air and exhaust, which is vital for personnel safety and equipment efficiency.

Functional Roles in Offshore Platforms’ Ventilation

Airflow Optimization: Elbows redirect airflow with minimal turbulence and pressure loss. Proper flow control alleviates strain on fans and reduces the risk of harmful gas buildup.

Structural Durability: Vibration and motion from waves can damage components not designed to tolerate dynamic loads. Aluminum elbow's mechanical strength ensures structural integrity even under offshore motion.

Corrosion Resistance: Saltwater exposure accelerates material degradation. Using marine-grade aluminum with adequate temper treatments prevents corrosion, extending the elbow lifecycle.

Lightweight Advantage: Compared to steel, aluminum elbows reduce the overall vent system weight, facilitating easier installation and reducing load on platform infrastructure.

Technical Specifications and Material Parameters

Alloy Selection and Tempering

The most common marine aluminum alloys for these elbows are 6061-T6 and 5083-H321, selected for their exacting balance of mechanical and chemical properties:

| Property | 6061-T6 Alloy | 5083-H321 Alloy |

|---|---|---|

| Chemical Composition (wt % approximate) | ||

| Silicon (Si) | 0.4 - 0.8 | 0.4 |

| Iron (Fe) | 0.7 max | 0.4 |

| Magnesium (Mg) | 0.8 - 1.2 | 4.0 - 4.9 |

| Chromium (Cr) | 0.04 - 0.35 | 0.05 - 0.25 |

| Copper (Cu) | 0.15 - 0.4 | 0.1 max |

| Manganese (Mn) | 0.15 max | 0.4 - 1.0 |

| Zinc (Zn) | 0.25 max | 0.25 max |

| Titanium (Ti) | 0.15 max | 0.015 max |

- 6061-T6 (solution heat-treated and artificially aged) provides high strength (~290 MPa tensile), good workability, and corrosion resistance

- 5083-H321 (strain-hardened and stabilized with Cr addition) offers superior corrosion resistance, especially in saltwater, though slightly less strength (~275 MPa tensile)

Mechanical Parameters

| Parameter | 6061-T6 | 5083-H321 |

|---|---|---|

| Tensile Strength | 290 MPa | 275 MPa |

| Yield Strength (0.2% offset) | 241 MPa | 145 MPa |

| Elongation at Break | 12-17% | 10-15% |

| Hardness (Brinell) | ~95 | ~75 |

| Density | 2.70 g/cm³ | 2.66 g/cm³ |

Implementation Standards and Compliance

For offshore applications, aluminum marine elbows typically adhere to these internationally recognized standards:

- ABS (American Bureau of Shipping): Rules for Building and Classing Offshore Vessels–covering design, material selection, fabrication, and testing requirements.

- DNV-GL: Offshore standards for material and weld joints on offshore structures ensuring mechanical stability under fatigue loads.

- ISO 15156/ NACE MR0175: Guidelines for resistance to sulfide stress cracking in offshore environments.

- ASTM B241, B221: Horizontal standards specifying production of extruded aluminum shapes and sheet plate for marine use.

Ventilation elbows produced under these standards undergo intensive inspections, including dimensional controls, tensile and bend tests, corrosion resistance assessments, and weld quality verifications—a non-negotiable standard for commercial-use offshore parts.

Installation and Corrosion Control Best Practices

Even the highest-spec marine aluminum undergoes stress in arduous sea settings. Proper implementation is as crucial as choice of material:

- Surface Preparation: Prior to installation, cleaning and priming surfaces minimize chloride deposit accumulation and brush-on high-performance marine sealants prevent galvanic interactions.

- Welding: When required, joints must follow controlled TIG welding with filler rods matching the aluminum alloy to avoid compromised durability.

- Thermal Treatment: Post-fabrication thermal treatments ensure retention of mechanical properties and microstructural uniformity.

- Periodic Inspection: Connection points of elbows receive detailed non-destructive testing (ultrasonic or dye-penetrant).

Distinctive Advantages of Aluminum Marine Elbows for Offshore Ventilation

- Enhanced Fatigue Resistance: The temper condition controlling grain structure variation helps balance strength with flexibility for dynamic offshore loading conditions.

- Reduced Maintenance Costs: Superior corrosion resistance significantly reduces failures due to rust-induced leaks or cracking.

- Lighter System Weight: Improves overall HVAC system lift-and-handle characteristics and reduces shipping costs.

- Advanced Fabrication Options: Modern CNC extrusion and welding allow custom complex ellipse or oval-shaped ducts for superior aerodynamic efficiency.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

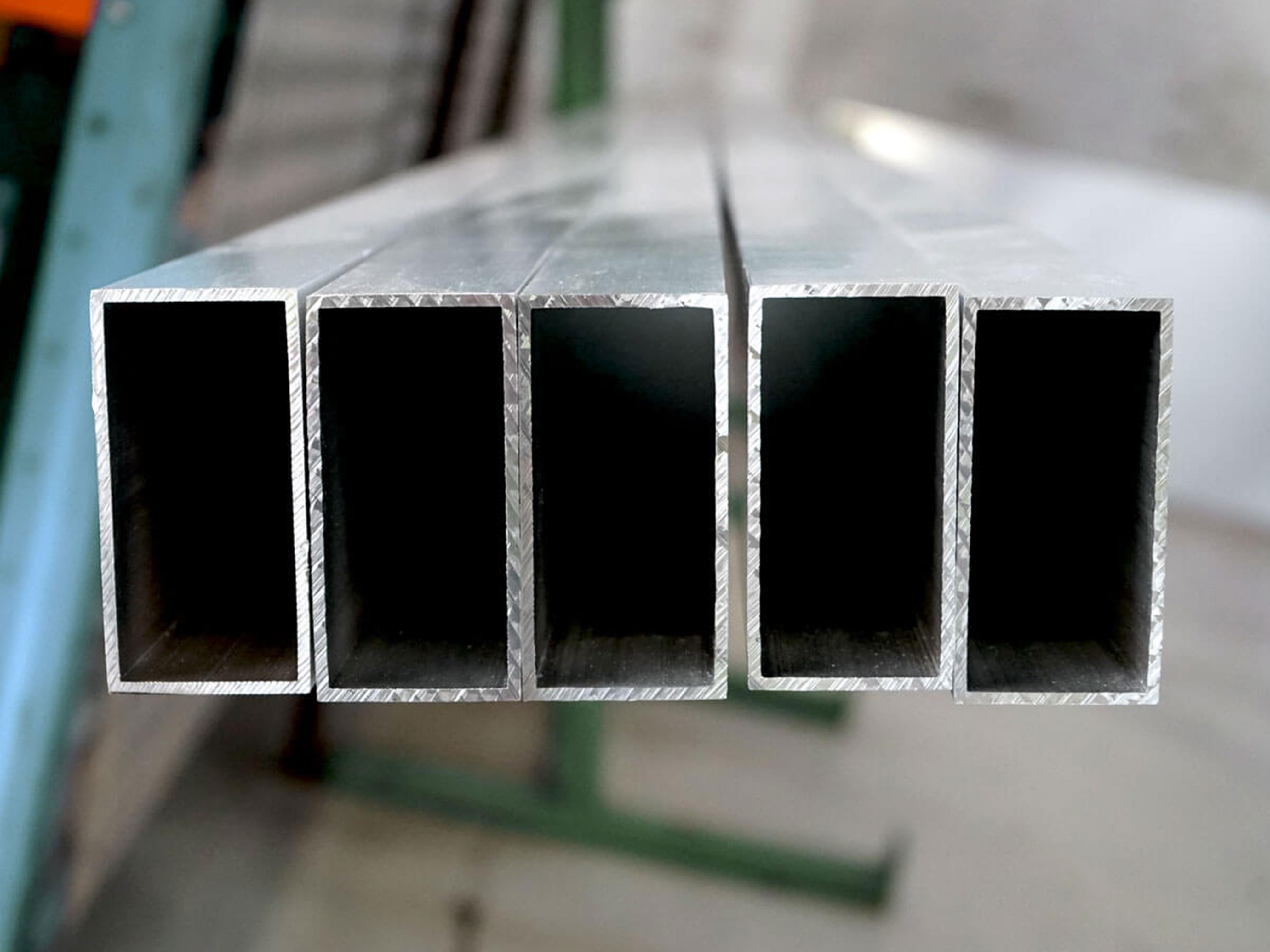

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

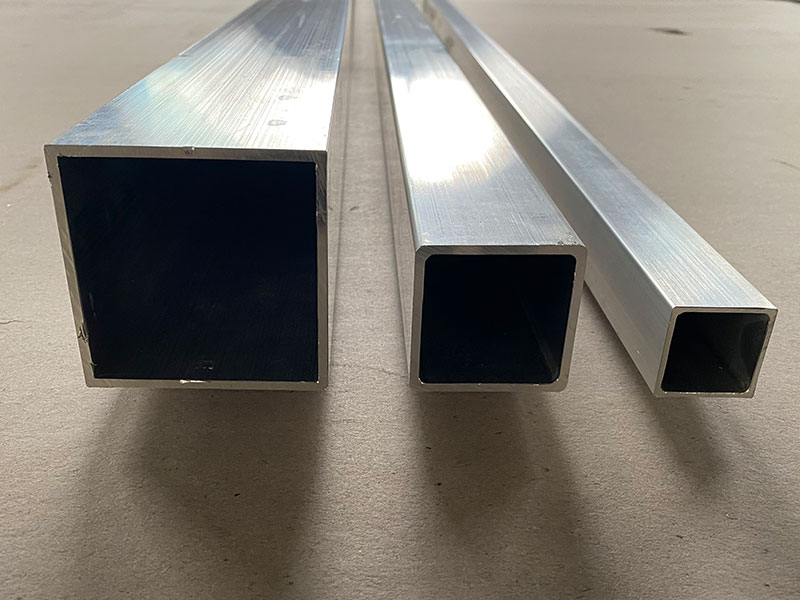

View DetailsMarine aluminum square tubes

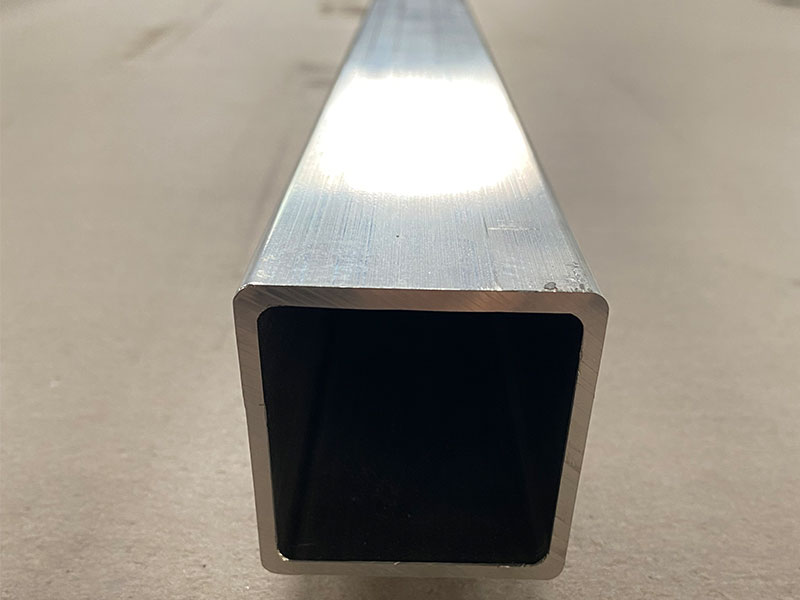

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View DetailsMarine Aluminum Pipe Elbow for Desalination Plant Connections

In modern desalination plants, the choice of piping components is critical to ensuring efficiency, longevity, and resistance to harsh marine environments.

View DetailsAluminum Elbow for Marine Exhaust Systems

In marine engineering, ensuring durability, corrosion resistance, and optimal flow dynamics of exhaust components is crucial for the longevity and performance of onboard systems.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View DetailsAluminum Elbow for High Pressure Saltwater Pipelines on Ships

In modern shipbuilding and marine engineering, the integrity and durability of high pressure saltwater pipelines stand as a critical priority.

View Details6061 Marine Aluminum Square Tubes for Yacht Construction

In the realm of yacht construction, materials play a pivotal role in defining vessel performance, durability, and aesthetics.

View Details

Leave a Message