Marine Aluminum Customized Shapes for Custom Ship Deck and Railing Systems

In the ever-evolving maritime industry, safety, durability, and performance take precedence. Marine aluminum, recognized for its lightweight yet robust characteristics, emerges as the quintessential material in the customization of ship deck and railing systems. With the advent of advanced manufacturing techniques and artistic innovations, marine aluminum is enabling shipbuilders to craft custom shapes that epitomize precise functionality while meeting strict regulatory standards.

The Persuasive Power of Aluminum Sections

Marine aluminum custom shapes serve various purposes in shipbuilding. Their principal functions include providing structural integrity, lightweight solutions for enhancing speed, and catering to aesthetic requirements for a polished finish. Distinct facets to be considered include:

- Structural Support: Custom extruded profiles can be tailored for diverse loading conditions ensuring exceptional stability at sea.

- Weight Reduction: Utilizing aluminum minimizes the weight burden of a ship, leading to improved fuel efficiency. This is particularly pivotal in leveraging performance optimization.

- Corrosion Resistance: Marine-grade alloys inherently display superior corrosion resistance, fabricating an enduring barrier to marine atmospheres.

- Versatility in Design: Custom shapes allow for innovative rail design, essential in conforming to safety regulations while accommodating aesthetics.

Materials and Alloys: A Deep Dive into Chemical Composition

Selecting the appropriate aluminum alloy is paramount. The choice frequently falls to specific grades suited for marine applications, notably series 5000 and series 6000 alloys. Below are properties of selected alloy types:

| Alloy | Significance | Composition_halation | Mechanical Properties & Conditions |

|---|---|---|---|

| 5083 | Very High Stress Resistance In Marine Environments | Al (≥92%), Fe (≥0.4%), Mg (4.0-4.9%), Mn (min 0.4%) | Yield Strength: 277 MPa |

| 6082 | Favorable for Extrusion & Versatile | Al (≥96%), Si (0.7-1.3%), Mg (1.2-1.8%), Mn (min 0.4%) | Yield Strength: 260 MPa AS per ML 2313 integral conditions |

| 6061 | Known for welding quality & strength | Al (≥90%), Mg (0.8-1.2%), Si (0.4-0.8%), Cr (>= 0.04%) | Yield Strength: 241 MPa |

Alloy Tempering and Implementation Standards

Aluminum tempering (heat treatment) can substantially influence resilience and operational endurance. Common temper specifications include H116 and H321 for mariner environments. H116 treated alloys reduce stress corrosion susceptibility, rendering them invaluable in structural applications in oceanic settings.

Compliance with standards is vital, as regulations dictated by societies such as the American Bureau of Shipping (ABS) or Det Norske Veritas (DNV) outline quality expectations. Precision measurement complies with ASTM standards to ensure efficacy on all external structures of the vessels as delineated through ISO 5798 stipulations.

Application Specifics: Decking and Railing Systems

In the construction of ship decks, barrier Removable Clips (BRC) use primarily implemented aluminum cross members ensuring effective slip-resistance surfaces and long-standing performance. Hyper-customizable railing profiles prevent human error by maximizing topple resistance while providing distinct lines for aesthetic appeal.

application facts:

- The integrity ratio of Decreasants to T Chelator rendering erosion resistance for outdoor overlooks tankers is paramount to smooth passenger experience.

- Marine-Grade bolts and Connectors integrated within the rail system crucially support pressure containment when waves strike unexpectedly elevation shifts (SAUCT).

Related Products

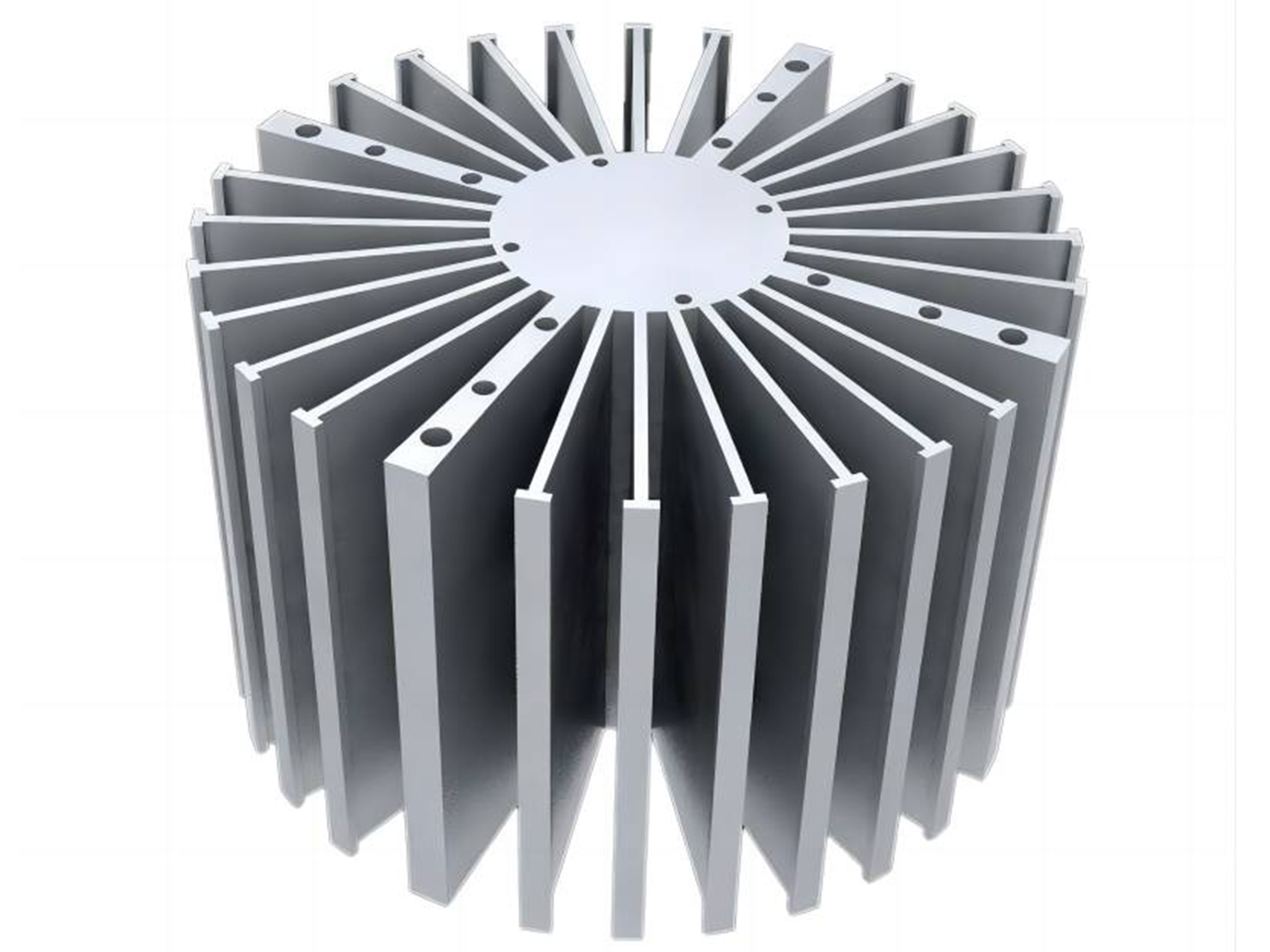

Marine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

6061 Marine Aluminum Fencing and Railings for Offshore Safety Solutions

The demand for durable and corrosion-resistant materials in marine and offshore applications has made 6061 marine aluminum a preferred choice for fencing and railings.

View Details6063 Marine Aluminum Heat Sink Profile for Seawater Resistant Cooling Systems for Boats

When it comes to boats and marine systems, efficient heat dissipation combined with exceptional corrosion resistance is crucial for reliable operations.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View DetailsMarine Aluminum Heat Sink Profile for Lightweight Offshore Cooling Systems

In the ever-challenging marine environment, offshore cooling systems must operate reliably, efficiently, and with minimal weight. This necessitates specialized materials and components, where marine aluminum heat sink profiles have emerged as a solution.

View DetailsMarine Aluminum Customized Shapes for Custom Ship Deck and Railing Systems

In the ever-evolving maritime industry, safety, durability, and performance take precedence. Marine aluminum, recognized for its lightweight yet robust characteristics.

View DetailsMarine Aluminum Fencing and Railings for Custom Boat Deck Guardrails

Marine Aluminum Fencing and Railings: The Ultimate Choice for Custom Boat Deck GuardrailsWhen it comes to constructing custom boat deck guardrails, marine aluminum fencing and railings are emerging as the industry’s top choice.

View Details

Leave a Message