Marine Aluminum Flat Bar for Boat Frame Reinforcement and Repair

In marine construction and maintenance, selecting the right materials for boat frame reinforcement and repair is critical for ensuring longevity, strength, and resistance to harsh sea environments. Marine aluminum flat bars provide an impeccable balance of toughness, corrosion resistance, and lightweight properties that make them an optimal choice. Our Marine Aluminum Flat Bars are designed specifically for these demanding applications, conforming to strict industry standards to meet the structural and environmental challenges faced by modern marine vessels.

Material Type: Marine-grade Aluminum Flat BarCommon Alloys: 5083, 5086, 6061, 5052 (depending on strength and corrosion resistance needs)Thickness Range: 3 mm to 20 mm (customizable)Width Range: 10 mm to 150 mm (customizable)Length Range: 1000 mm to 6000 mm (or cut-to-length options)Surface Finish: Mill finish or customized anodizing/plating availableDelivery Condition: Tread (T), Annealed (O), or Heat Treated Temper (T6, T651, etc.)

Alloy Composition and Chemical Properties

| Element | 5083 Alloy (%) | 5086 Alloy (%) | 6061 Alloy (%) | 5052 Alloy (%) |

|---|---|---|---|---|

| Aluminum (Al) | Balance (~95.0) | Balance (~94.2) | Balance (~97.9) | Balance (~97.25) |

| Magnesium (Mg) | 4.0 – 4.9 | 3.5 – 4.5 | 0.8 – 1.2 | 2.2 – 2.8 |

| Manganese (Mn) | 0.4 – 1.0 | 0.5 – 1.0 | 0.15 – 0.4 | 0.1 – 0.5 |

| Chromium (Cr) | 0.05 – 0.25 | 0.05 – 0.25 | 0.04 – 0.35 | 0.15 – 0.35 |

| Silicon (Si) | 0.4 | 0.4 | 0.4 – 0.8 | 0.25 |

| Iron (Fe) | 0.4 | 0.5 | 0.7 | 0.4 |

| Copper (Cu) | 0.1 | 0.1 | 0.15 – 0.4 | 0.1 |

Note: Composition ranges are generalized; precise measurements are available upon specification.

Mechanical Properties

| Property | 5083 (H111) | 5086 (H321) | 6061 (T6) | 5052 (H32) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 317 – 350 | 260 – 310 | 310 – 350 | 220 – 270 |

| Yield Strength (MPa) | 145 – 215 | 180 – 250 | 270 – 310 | 100 – 180 |

| Elongation (%) | ≥ 12 | ≥ 10 | ≥ 10 | ≥ 10 |

| Hardness (Brinell, HB) | 75 – 95 | 80 – 100 | 95 – 115 | 60 – 80 |

| Density (g/cm³) | 2.66 | 2.66 | 2.70 | 2.68 |

Temper Designations and Heat Treatment

- O Temper: Fully annealed for maximum ductility. Typically employed when significant forming or reshaping is needed prior to installation or welding.

- H Series Tempers (e.g., H111, H321, H32): Strain-hardened tempers that provide a balance between strength and ductility—favored in moderate-bearing applications.

- T6 Temper: Solution heat treated and artificially aged to produce high strength with good corrosion resistance—common for structural vessel components exposed to heavy stresses.

- T651 Tempers: Similar to T6, with stress relief by stretching, reducing residual stresses and improving machinability.

Industry Standards and Certifications

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate, governs tensile strength, chemical composition, and quality testing.

- ISO 6361: Covers general requirements for aluminum flat rolled products, including flat bars used in marine industry.

- ABS & Lloyd’s Register Certifications: Our marine aluminum products meet classification society standards important for structural applications and insurance requirements.

- MIL-DTL-24779: Military Specification Aluminium Alloy Plate, Provides resistance criteria, often referenced in design.

Advantages for Marine Applications

- Excellent Corrosion Resistance: High Mg-content 5xxx series alloys like 5083 and 5086 strongly resist saltwater corrosion, offering longer service life.

- Lightweight but Strong: Achieve robust load-bearing capacity without increased vessel weight, boosting fuel efficiency and payload capacity.

- Weldability: Outstanding weld characteristics with appropriate procedure, important for repairs and custom reinforcements on existing vessels.

- Formability: Easily fabricated and formed into complex sectional parts for customized frame repairs.

- Resistance to Cracking and Fatigue: High ductility and ability to absorb impact and stress observed in heavy seas.

Typical Applications in Marine Engineering

- Structural frame rails and transverse members

- Hull reinforcing stiffeners

- Deck house frameworks

- Gangways and railing components

- Marine repair brackets & seam reinforcements

- Accessory mounts for navigation and communication equipment

Installation and Handling Recommendations

- Pre-conditioning: Prior to welding or bending, flat bars should be cleaned to remove mill oils and contaminants and stress-relieved if required.

- Welding: Use specified aluminum-grade filler materials (e.g., ER5356 for 5xxx alloys, ER4045 for 6xxx alloys). Applying post-weld heat treatments can help prevent sensitization and corrosion.

- Storage: Avoid direct contact with moisture and soluble salts. Utilize protective coatings or climate-controlled storage areas.

- Machining: Select appropriate tooling to prevent galling. Carbide tools are recommended. Use cooling fluids suitable for aluminum machining.

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

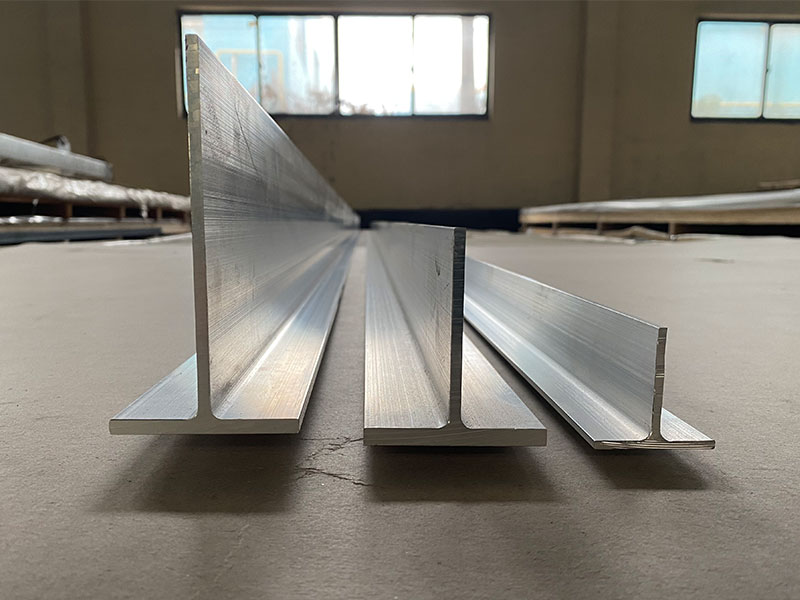

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

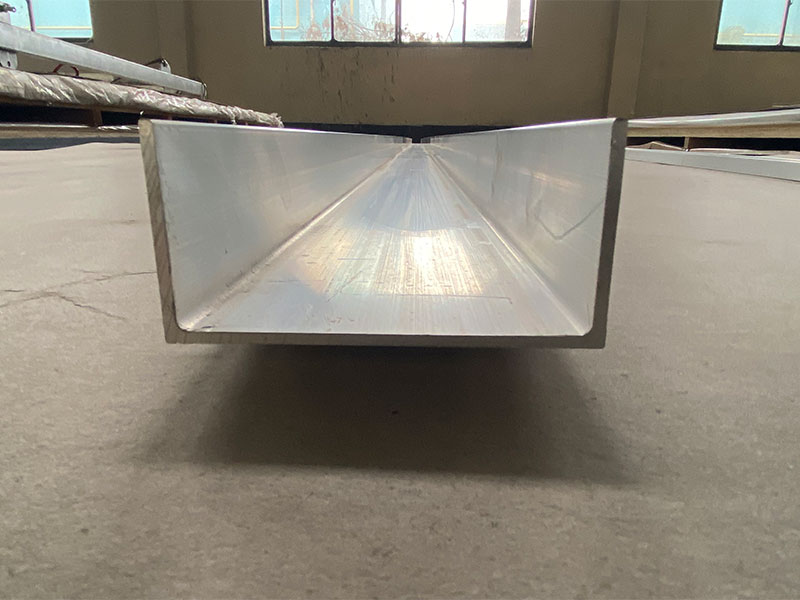

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View DetailsMarine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity.

View Details

Leave a Message