Marine Aluminum Flat Bar for Heavy Duty Coastal Engineering Projects

Marine aluminum flat bars are a pivotal material choice for heavy duty coastal engineering projects due to their superior strength, corrosion resistance, and durability in harsh saline environments. These specialized flat bars serve critical functions in constructing robust, long-lasting maritime structures exposed to coastal and offshore conditions.

Functions and Importance

In coastal engineering, materials face multifaceted challenges such as continuous exposure to saltwater, mechanical stress, and varying weather conditions. Marine aluminum flat bars offer a reliable solution by delivering excellent mechanical properties combined with outstanding corrosion resistance, significantly enhancing the lifecycle and safety of marine infrastructures.

functions include:

- Structural Support: Providing foundational and connective elements for docks, piers, sea walls, and offshore platforms.

- Corrosion Resistance: Maintaining structural integrity by resisting the oxidative effects of prolonged saltwater exposure, which is critical in marine environments.

- Lightweight Strength: Facilitating easier handling and installation compared to heavier metals like steel, reducing time, labor, and costs.

- Flexibility for Fabrication: Allowing versatile machining, welding, and coating for tailored marine applications.

Common Applications in Coastal Projects

Marine aluminum flat bars find extensive use in the following coastal engineering contexts:

- Reinforcement beams for marine wharfs and jetties.

- Structural components in seawall constructions and waterfront infrastructures.

- Frames and foundational parts of offshore oil rigs and wind turbine platforms.

- Formwork and bracing systems temporarily supporting coastal embankments.

- Marine ladders, railing systems, and stairways exposed to tidal zones.

- Fabrication of floating dock elements or marine container bases.

Their adaptability and reliability form a fundamental part of sustainable, high-performance coastal engineering design.

Technical Specifications and Alloy Details

Marine aluminum flat bars are typically fabricated from high-quality aluminum alloys designed to optimize both mechanical strength and corrosion resistance.

Common Alloys and Temper Designations

The most frequently used marine-grade alloys include 5052 and 5083 aluminum alloys, favored for their excellent performance in saltwater environments.

| Alloy | Temper | Prevalent Use | Description |

|---|---|---|---|

| 5052 | H32, H34 | Widespread marine structural parts | Good corrosion resistance, moderate strength. |

| 5083 | H32, H321 | Heavier load capacity structures | Higher strength, outstanding corrosion traits. |

Chemical Composition (Wt.%)

| Element | 5052 Alloy Min | 5052 Alloy Max | 5083 Alloy Min | 5083 Alloy Max |

|---|---|---|---|---|

| Aluminum | Balance | Balance | Balance | Balance |

| Magnesium | 2.2 | 2.8 | 4.0 | 4.9 |

| Manganese | 0.10 | 0.40 | 0.4 | 1.0 |

| Chromium | - | - | 0.05 | 0.25 |

| Iron | - | 0.40 | - | 0.4 |

| Copper | - | 0.10 | - | 0.1 |

| Zinc | - | 0.10 | - | 0.25 |

| Silicon | - | 0.25 | - | 0.4 |

Mechanical Properties

| Property | 5052 H32 | 5083 H321 |

|---|---|---|

| Tensile Strength (MPa) | 228 – 275 | 317 – 350 |

| Yield Strength (MPa) | 138 – 193 | 215 minimum |

| Elongation (%) | 10 – 14 | 12 – 18 |

| Hardness (Brinell) | ~75 | ~90 |

| Density (g/cm³) | 2.68 | 2.66 |

Implementation Standards and Quality Assurance

Marine aluminum flat bars intended for heavy-duty coastal engineering conform to internationally recognized standards guaranteeing consistency, reliability, and safety in marine conditions. Familiar norms include:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- BS EN 485-2: Aluminum and Aluminum Alloys - Sheet, Strip and Plate, Mechanical Properties.

- ISO 6361: Wrought Aluminum and Aluminum Alloy Sheets - Chemical Composition and Mechanical Properties.

- AWS D17.2M/D17.2: Welding standards suitable for marine aluminum alloys ensuring structural integrity after joining.

Careful adherence to these standards ensures material traceability, quality control, and compliance with project-specific requirements.

Tempering and Treatment Conditions

Proper alloy tempering enhances mechanical properties and corrosion resistance, essential in marine conditions.

| Alloy | Temper | Process | Outcome |

|---|---|---|---|

| 5052 | H32 | Strain hardened and stabilized | Moderate strength and good ductility. |

| 5083 | H321 | Solution heat treated, cold work stabilized | High strength and exceptional corrosion resistance. |

Heat treatments combined with controlled cold working stabilize the molecular structure, optimizing resistance to stress corrosion cracking typical in marine environments.

Advantages Over Other Materials

Marine aluminum flat bars offer distinct benefits over steel and other metal alternatives traditionally used in coastal projects:

- Reduced Weight: Aluminum is approximately one-third the weight of steel, lowering mechanical loads and enabling easier fabrication.

- Enhanced Corrosion Resistance: Exploiting the natural formation of a thin oxide layer, aluminum withstands saltwater decay without the frequent maintenance associated with steel.

- Superior Weldability: Modern marine alloys respond well to precision welding methods, streamlining assembly.

- Recyclability: Being environmentally preferential, aluminum outcomes sustain a circular economy approach.

Related Products

Marine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

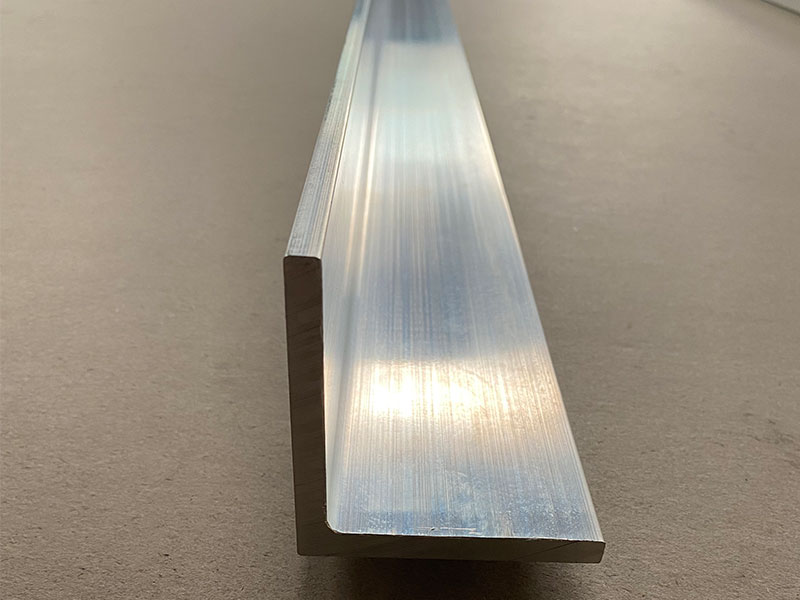

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View DetailsMarine Aluminum Angles for Boat Hull Frame and Structural Support

When it comes to marine construction, selecting the right materials is crucial to ensure durability, corrosion resistance, and structural integrity.

View Details5083 Marine Aluminum Channels for Lightweight Boat Deck Design

The marine industry continually seeks efficiency and versatility in boat construction. Among the materials available, 5083 marine aluminum channels have emerged as a stellar choice for lightweight boat deck design.

View DetailsMarine Aluminum Angles for Custom Marine Vessel Deck Parts

In the demanding maritime environment, the structural integrity and durability of vessel deck parts are paramount. Marine aluminum angles have emerged as a critical solution in the customization and reinforcement of these components.

View Details5052 Marine Aluminum Angles for Heavy Duty Marine Applications

In the world of marine applications, the choice of materials can significantly influence performance and longevity. For heavy-duty usage, marine aluminum angles, particularly 5052 Marine Aluminum angles, come out as premier contenders.

View Details

Leave a Message