Marine Aluminum Angles for Boat Hull Frame and Structural Support

When it comes to marine construction, selecting the right materials is crucial to ensure durability, corrosion resistance, and structural integrity. Marine aluminum angles are engineered to meet the harsh demands of saltwater environments while providing robust support in boat hull frames and other structural applications.

Features of Marine aluminum angles

- Superior Corrosion Resistance: Aluminum naturally forms a protective oxide layer; marine aluminum alloys are further enhanced to resist pitting and crevice corrosion typical of seawater exposure.

- High Strength-to-Weight Ratio: Lightweight yet strong, this material supports substantial loads without adding unnecessary weight to the vessel.

- Excellent Weldability and Fabricability: Easy to cut, weld, and shape, aluminum angles facilitate versatile design and customization during boat building and repairs.

- Low Maintenance: Durable and resistant to marine bio-fouling, these angles require minimal upkeep throughout the lifespan of the vessel.

- Thermal and Electrical Conductivity: Aluminum's good conductivity properties assist in dissipating heat and electric charges, reducing structural risks in marine systems.

Chemical Composition of Common Marine Aluminum Alloys

Marine aluminum angles are often supplied in specific alloys that enhance corrosion resistance and mechanical properties. Below is a typical chemical composition for two widely used alloys: 5083 and 6061.

| Element | Alloy 5083 (wt %) | Alloy 6061 (wt %) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 4.0 – 4.9 | 0.8 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 | 0.15 – 0.4 |

| Silicon (Si) | 0.4 max | 0.4 – 0.8 |

| Iron (Fe) | 0.4 max | 0.7 max |

| Copper (Cu) | 0.1 max | 0.15 – 0.4 |

| Chromium (Cr) | 0.05 – 0.25 | 0.04 – 0.35 |

| Zinc (Zn) | 0.25 max | 0.25 max |

| Titanium (Ti) | 0.05 max | 0.15 max |

| Others | Trace | Trace |

Technical Specifications

Aluminum angles for marine applications come in multiple sizes and tempers customized to suit various structural requirements. Below is a standardized example table expressing common technical parameters.

| Parameter | Typical Range / Units | Notes |

|---|---|---|

| Temper | O, T4, T6 | O: Annealed, T4: Solution treated, T6: Solution treated and artificially aged |

| Thickness | 3 – 25 mm | Custom thickness available |

| Width / Leg Length | 20 – 150 mm | Vary depending on frame design |

| Length | Standard 6m / Custom cut levels | Usually supplied in made-to-measure |

| Density | ~2.70 g/cm³ | Typical for aluminum alloys |

| Tensile Strength | 215 – 310 MPa | Varies by alloy and temper |

| Yield Strength | 125 – 275 MPa | Performance to withstand mechanical load |

| Elongation at Break | 10 – 22 % | Ductility level |

| Corrosion Resistance | Excellent | Especially for alloy 5083 |

Applications of Marine aluminum angles

Marine aluminum angles serve highly specialized roles in the maritime industry. Notable usage includes:

- Boat Hull Frames: To provide structural reinforcement in the longitudinal and transverse ribs; ensures hull rigidity and impact resistance from waves and obstacles.

- Support Frameworks: Used in deck framing, cabin structures, and superstructures where lightweight, but robust performance is required.

- Mounting Brackets and Fittings: Due to corrosion resistance and waterproof properties, often employed as angles for bracketry supporting marine equipment.

- Machinery Bases and Platforms: In marine engine rooms where vibration resistance and meet strength with minimal weight are important.

- Ship and Yacht Repair: For refurbishing damaged structural angles without compromising corrosion safeguards and durability standards.

Why Choose Our Marine aluminum angles?

Our Marine aluminum angles are crafted following stringent quality assurance processes, testing each batch against international marine standards. With experience gained from supporting tens of thousands of square meters of boat frame elements, our products deliver exceptional strength, corrosion resistance, and longevity. We also offer customization to tailored dimensions, tempers, and surface treatments to precisely meet each project requirement.

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

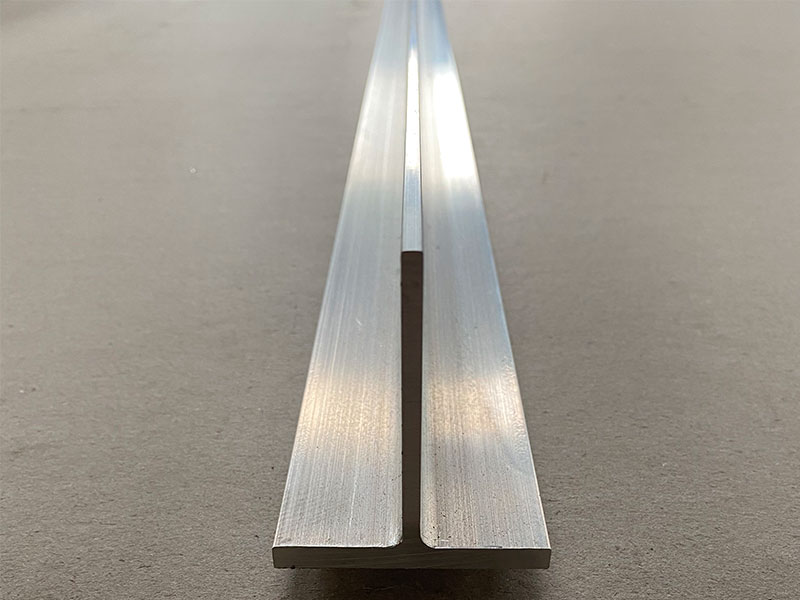

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

5083 Marine Aluminum Z Shaped Sections for Boat Frame and Hull Customization

When it comes to marine structures, the choice of materials is crucial for durability, performance, and safety. One material that consistently stands out in the maritime industry is 5083 marine aluminum.

View Details5086 Marine Aluminum I Beams for Custom Marine Vessel Design

Aluminum 5086 is a high-strength, corrosion-resistant alloy strategically engineered for marine applications. Its benefits, such as excellent real-world longevity and ease of customization, make it a favored choice for shipbuilding or repair processes.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View Details5083 Marine Aluminum Z Shaped Sections for Custom Marine Boat Parts

When it comes to constructing durable, lightweight, and corrosion-resistant components for marine vessels, material selection is crucial. 5083 Marine Aluminum Z Shaped Sections offer an optimal combination of strength, formability.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details5083 Marine Aluminum Channels for Coastal Marine Engineering Projects

In the realm of coastal marine engineering, material selection is crucial for ensuring the durability, performance, and safety of structures exposed to harsh sea environments.

View Details

Leave a Message